КЛАСИЧНИЙ ЛАВАШ

Класичний вірменський лаваш із простою рецептурою та технологією виробництва став одним із найпопулярніших у світі видів борошняних виробів. UTF GROUP випускає промислове лавашне обладнання з продуктивністю 30-500 кг/год.

Виробництво широкого асортименту обладнання для різних видів лаваша.

Підприємство виробляє готові рішення для виготовлення лаваша з продуктивністю від 20 до 500 кг/год, які підходять для малого, середнього або великого бізнесу.

Виробництво лаваша високої якості, сучасна система управління, надійна цілодобова експлуатація.

UTF-GROUP, один із найбільших виробників промислових ліній та обладнання для виробництва національних видів хліба у Східній Європі.

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Класичний вірменський лаваш із простою рецептурою та технологією виробництва став одним із найпопулярніших у світі видів борошняних виробів. UTF GROUP випускає промислове лавашне обладнання з продуктивністю 30-500 кг/год.

Севанський лаваш зі складною рецептурою та технологією приготування нині набирає популярності у всьому світі. UTF GROUP випускає промислові лінії для випуску севанського лавашу з продуктивністю до 80 кг/год.

Гарнійський лаваш із насиченим смаком та особливою технологією випічки завоював любов поціновувачів лавашу у багатьох країнах. UTF GROUP – єдиний виробник промислового обладнання для випуску гарнійського лаваша.

На лініях UTF-GROUP можливе приготування лавашу для фаст-фуду (шаурми, хот-догів тощо) – він не рветься і не ламається на згинах, а також може допікатися разом із начинкою.

Для отримання лавашного тіста подають попередньо підготовлену сировину (просіяне борошно, підігріта вода), дозуючи його вручну або за допомогою автоматичних дозаторів згідно з рецептурою.

Потім подають підготовлену сировину в тістоміс, де виконується його замішування. Застосування обладнання UTF-GROUP, спеціально розробленого для підготовки лавашного тіста, забезпечує виробництво продукту найвищої якості.

Тісто подається в автоматичну камеру розстоювання, де в оптимальних умовах відбувається процес розстоювання тіста, що забезпечує еластичність його поверхні і ефективний процес бродіння необхідний для насиченого смаку готового лаваша.

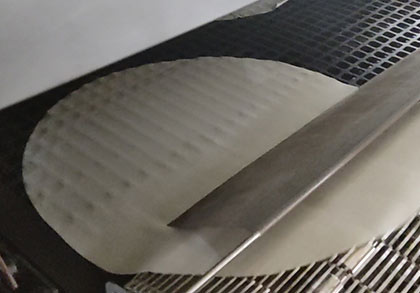

Готове тісто подають на комплект машин, які зі стрічки тіста формують заготовки лаваша. Процес формування заготовок може відбуватися в автоматичному та напівавтоматичному режимі.

У напівавтоматичному режимі на розкатному обладнанні формують лаваш із округлих порцій тіста заданої ваги та розміру, отриманих на ділильній машині.

У цьому режимі заготовки формують із прокатаної у двох напрямках стрічки тіста. Квадратні та прямокутні заготовки отримують за допомогою дискових ножів та гільйотини, круглі та овальні – ріжучих барабанів.

Випікання продукту в печах, які забезпечують найсприятливіші умови для випікання готових виробів. Тунельні печі виробництва UTF-GROUP оптимізовані для вірменського лаваша.

Газова або електрична тунельна піч для тонкого лаваша із шириною пода до 1000 мм гарантує ідеальну випічку. Підбір печі з урахуванням продуктивності обладнання забезпечує максимальну економічну ефективність.

Для виробництв з невеликими обсягами випуску продукції використовується компактна пічка для лаваша з прямокутним або круглим подом.

Зволоження після процесу випічки є важливим етапом виробництва, що дозволяє отримати м’який лаваш, готовий до упаковки та вживання.

Автоматичні лінії лаваша UTF-GROUP можуть бути доповнені комплектом обладнання для виробництва пшеничних та мультизернових чіпсів

На автоматичних лініях можна організувати виробництво тонкої пшеничної тортильї. За рахунок великих розмірів і меншої товщини такий вид тортильї набув широкого застосування в мережах фаст-фуду.

сертифіковано відповідно до вимог світових стандартів, для Євросоюзу надається сертифікат РЄ та Євро-1, обладнання відповідає європейським вимогам щодо гігієни та безпеки

гарантія надійної роботи нових моделей обладнання – нові конструкторські рішення попередньо відпрацьовуються на реальному виробництві

надання компанією професійних консультацій з технології та особливостей виробництва лаваша

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?

Лаваш — це відомий з давніх-давен вірменський продукт, який давно вже переступив межі одного народу і став всесвітнім надбанням. Він є дуже тонким прісним бездрожжевим хлібним виробом. Мінімальна кількість інгредієнтів (борошно, сіль та вода), проста технологія приготування і, найважливіше, чудовий смак забезпечили йому популярність як безпосередньо як хлібний продукт, так і в ролі різних страв. Мала товщина, гнучкість та міцність вірменського лаваша допомогли йому завоювати популярність у фаст-фуді, де його використовують для загортання різноманітних виробів — шаурми, люля-кебаб, хот-догів, ролів та багатьох інших.

UTF-GROUP понад 25 років працює у галузі виробництва обладнання для виготовлення вірменського лаваша. Ніхто не працював у цьому напрямку довше і краще, ніж ми! Традиційний процес виробництва лаваша вимагає відточених навичок при формуванні та випіканні виробів, а також значних трудовитрат протягом усіх етапів виготовлення. Усе це призводить до високої собівартості одиниці готової продукції. UTF-GROUP замінює копітку ручну працю машинною, яка не вимагає від формувальників та пекарів високої кваліфікації, а то й зовсім замінює їх автоматами. Обладнання з різним рівнем автоматизації – від автоматизації окремих процесів розкочування та випікання до повністю автоматизованого виробництва – максимально повно відповідає планам та стратегії розвитку будь-якого виробника від дрібних пекарень до великих заводів.

Україна, Київська область,

Києво-Святошинський район, Михайлівська Рубежівка,

Урочище Потоки, 2