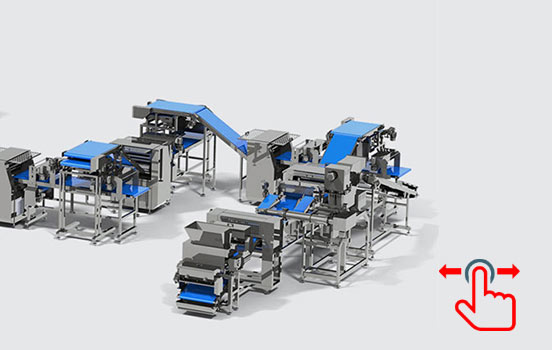

Виробництво дріжджового листкового тесту без застосування холодильного тунелю

АВТОМАТИЧНА ЛІНІЯ

ЛАМІНАЦІЇ ЛИСТКОВОГО ТІСТА

Продуктивність до 1000 кг/год

Модульна конструкція для легкої адаптації лінії під приміщення та існуюче виробниче обладнання.

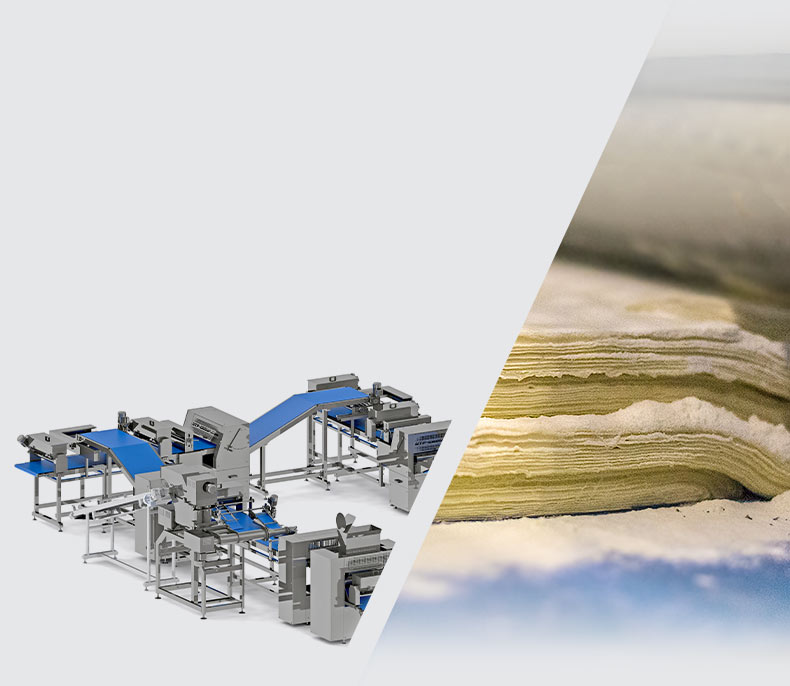

Виготовлення різних видів листкового тіста: дріжджового, бездрожжового, датського. Висока якість листкового тесту з додаванням мінімальної кількості жиру (до 15%)

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում