Переміщення відсаджувальної машини вздовж сталевого пода печі для підвищення продуктивності відсадження

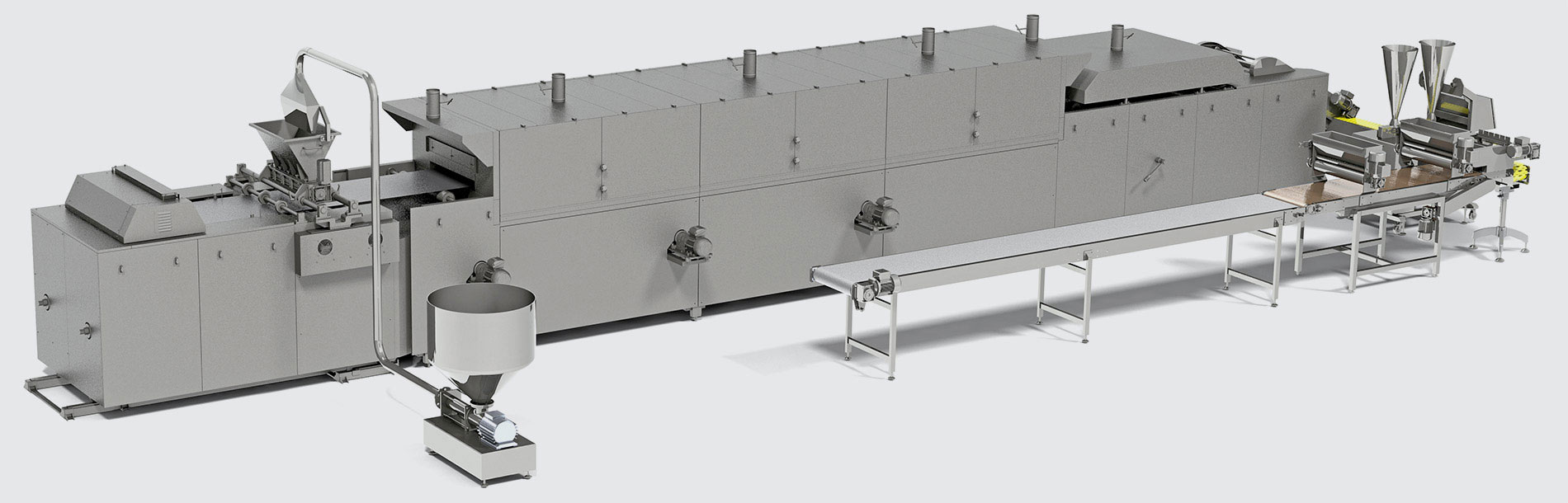

АВТОМАТИЧНА ЛІНІЯ

ДЛЯ ВИРОБНИЦТВА ЕКЛЕРІВ,

ПРОФІТРОЛІВ І ВІДСАДНОГО ДРУКУ

Продуктивність до 1000 кг/год.

Автоматизація основних технологічних процесів. Повна автоматизація процесу приготування заварних тістечок.

Зовнішня поверхня готової продукції без розривів. Великий асортимент виробів із заварного та пісочного тіста. Компактне компонування.

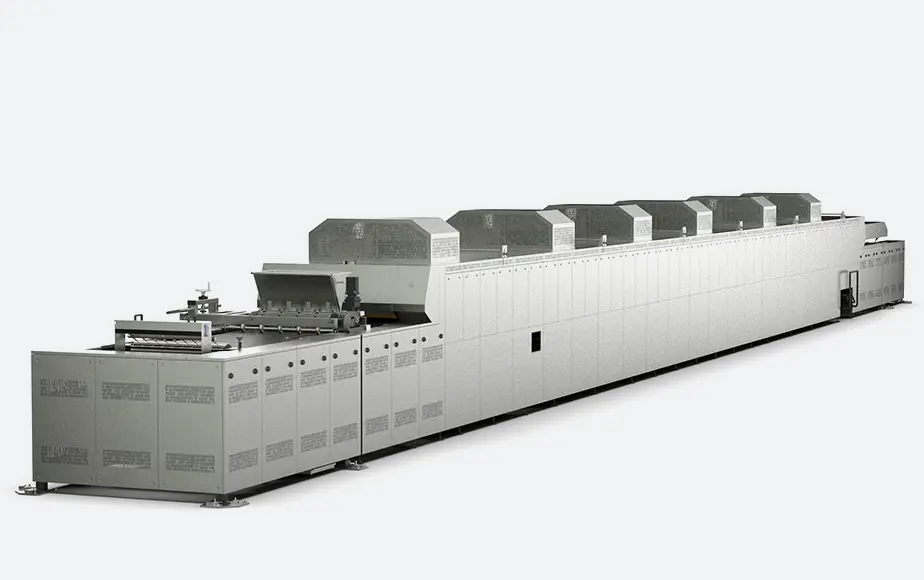

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում