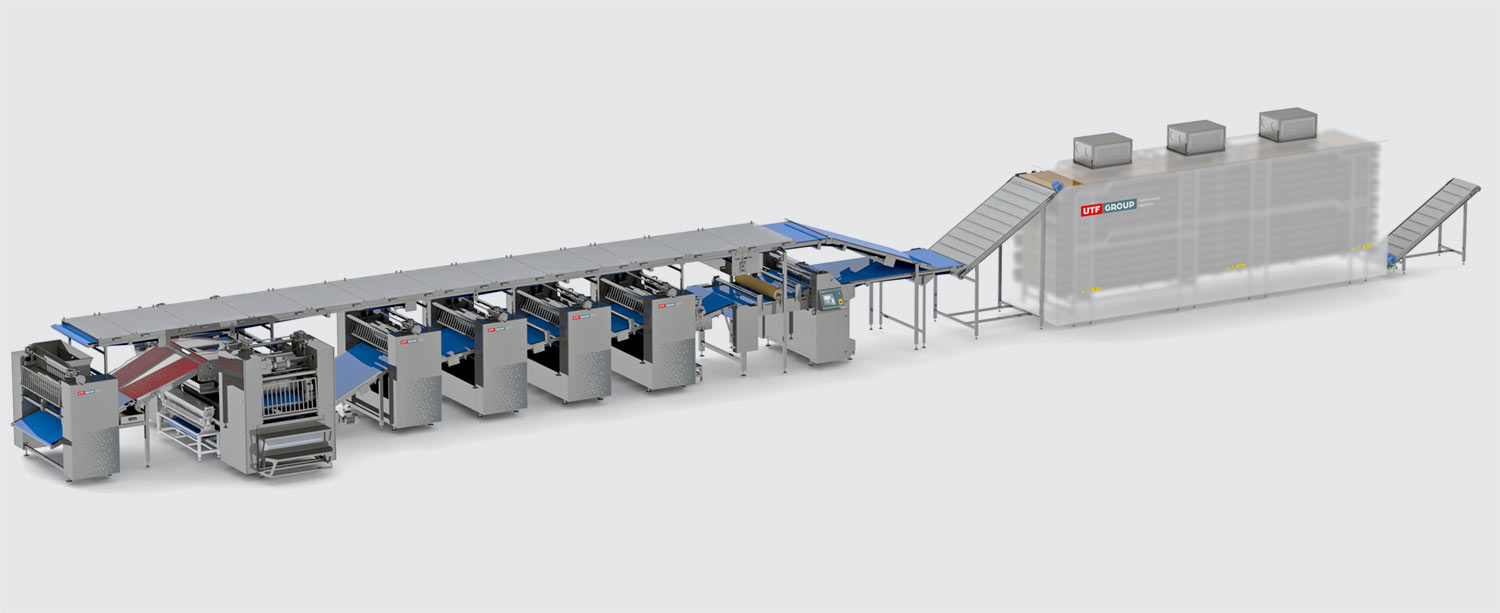

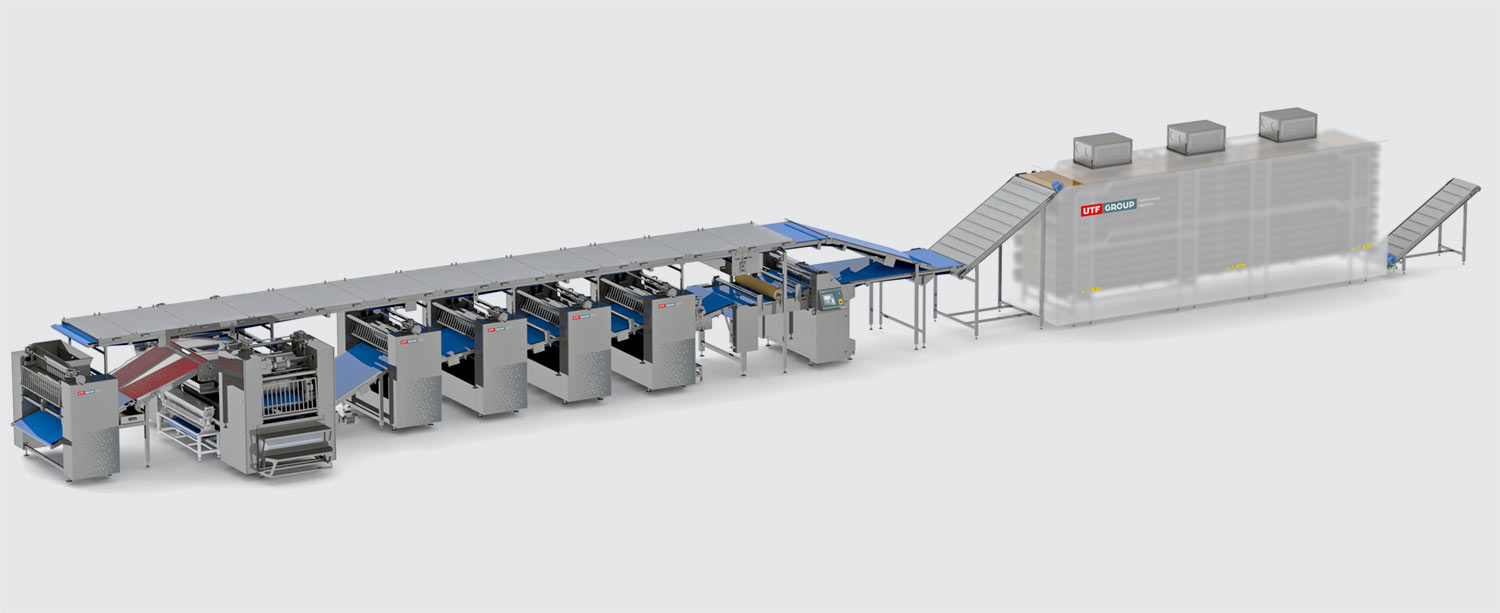

ПОВОРОТНИЙ НОЖОВИЙ МОДУЛЬ

Установка поворотного ножового модуля з чотирма змінними ріжучими барабанами скорочує час переходу на продукцію іншого розміру.

Висока продуктивність обладнання. Повна автоматизація процесу виробництва. Робота у безперервному цілодобовому режимі.

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

ПРОДУКТИВНІСТЬ

ВІД 100 КГ/ГОД

ВСТАНОВЛЕНА ПОТУЖНІСТЬ

ДО 92 КВТ

ОБСЛУГОВУЮЧИЙ ПЕРСОНАЛ

2 ЛЮДИНИ

ЗАЙМАНА ПЛОЩА

ВІД 45 М2

Установка поворотного ножового модуля з чотирма змінними ріжучими барабанами скорочує час переходу на продукцію іншого розміру.

Можливе встановлення системи конвеєрів для автоматичного повернення обрізків тіста, що залишилися після вирізування заготовок зі стрічки тіста, в екструдер для повторного використання.

Для нагрівання повітря в сушильній камері можуть застосовуватись електричні нагрівальні елементи, газові пальники та гаряча вода, нагріта бойлером (може працювати на будь-яких видах палива).

Для автоматизації пакування папад можна укомплектувати лінію дворядним укладачем, який формує стопки із заданим числом виробів.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?