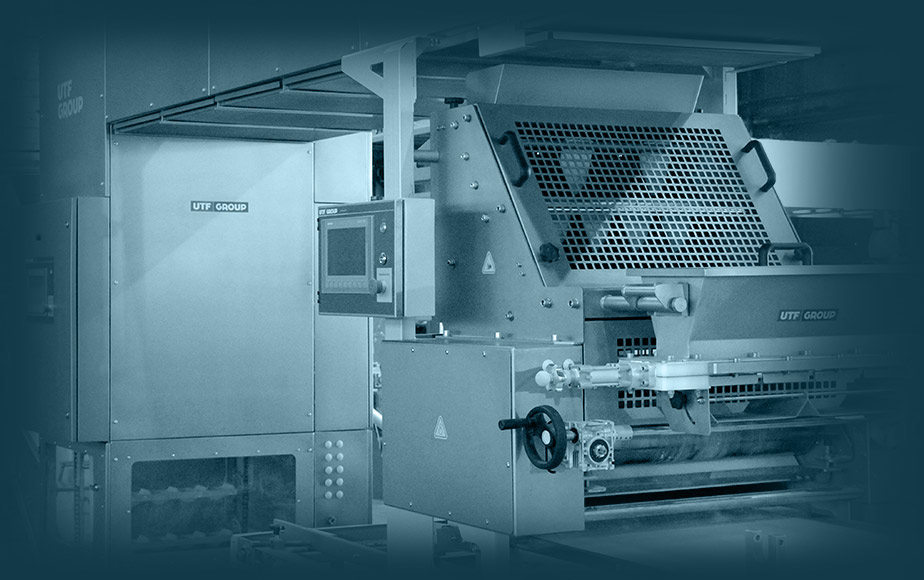

ОБЛАДНАННЯ

ДЛЯ ХАРЧОВОЇ ПРОМИСЛОВОСТІ

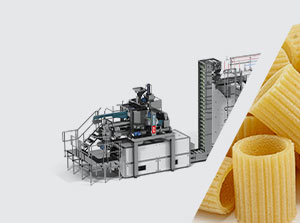

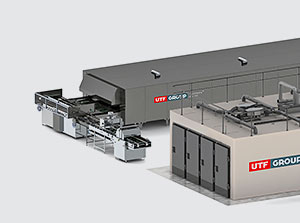

Автоматичні лінії, комплекси, вузли та окремі одиниці обладнання для виробництва широкого асортименту продукції харчової галузі

у хлібопекарській промисловості, кондитерському виробництві, виробництві макаронних виробів та снеків, обладнанні для фастфуду

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում