DEPOSITING MACHINE

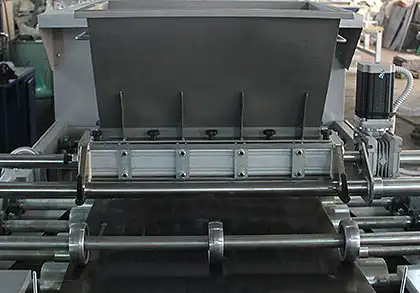

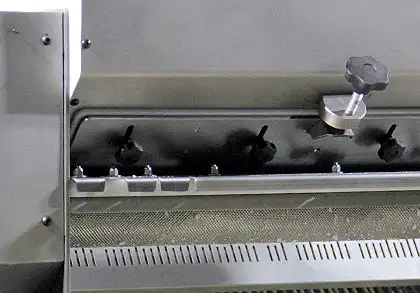

Depositing machine provides the forming of a sponge layer with a stable quality over the entire width.

Equipment for the production of a large assortment of cakes, pastries and rolls made of sponge and sand dough. Modern technologies, the best technical solutions and an individual approach to each project provide the maximum economic effect for both small and large confectionery productions.

UTF GROUP is a Ukrainian manufacturer and developer of confectionery equipment with over 25 years of experience

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

Depositing machine provides the forming of a sponge layer with a stable quality over the entire width.

Along with obtaining sponge layer, depositors make it possible to produce confectionery made of sand dough.

Baking of biscuit layer and sand dough products is made in a tunnel oven. It is possible to use both the UTF GROUP confectionery electric ovens and ovens of various types and designs from other manufacturers.

The forming of dough pieces is performed by cutting a sponge layer into the pieces of a given size using a system of longitudinal and transverse knives.

For a wide range of confectionery products, a large variety of machines for decoration is used — machines and units for liquid fillings injection, sprinkling with bulk ingredients, two- and multi-tiered laying, wrapping, rolling, and many others are among them.

Cake layers for «Napoleon» are made from puff pastry are cut out from a dough ribbon, which is fed to the line in the form of a semi-finished product wound on rolling pins or directly from the puff pastry lamination line.

Cake layers for «Medovik» are made from shortcrust pastry are cut out from a dough strip, which is formed by a roller extruder installed on the line.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?

The main difficulty in automating the processes of making products of sponge and sand dough is the need to obtain a wide range.

Therefore, at most enterprises, only the production of dough pieces and baked semi-finished products is automated, and decorating of finished products is done manually.

Full automation of production requires an individual approach to project implementation, high flexibility of equipment and large production volumes. But due to the fact that it provides the minimum cost of production, it is becoming increasingly widespread.

Almost all people, regardless of gender, age or place of residence, love sweets. Modern confectionery industry, which produces sweets for every taste, is based on this need.

One of the most common confectionery products are cakes and pastries made from sponge and sand dough.