UTF GROUP presents the highest capacity lavash production line in the world

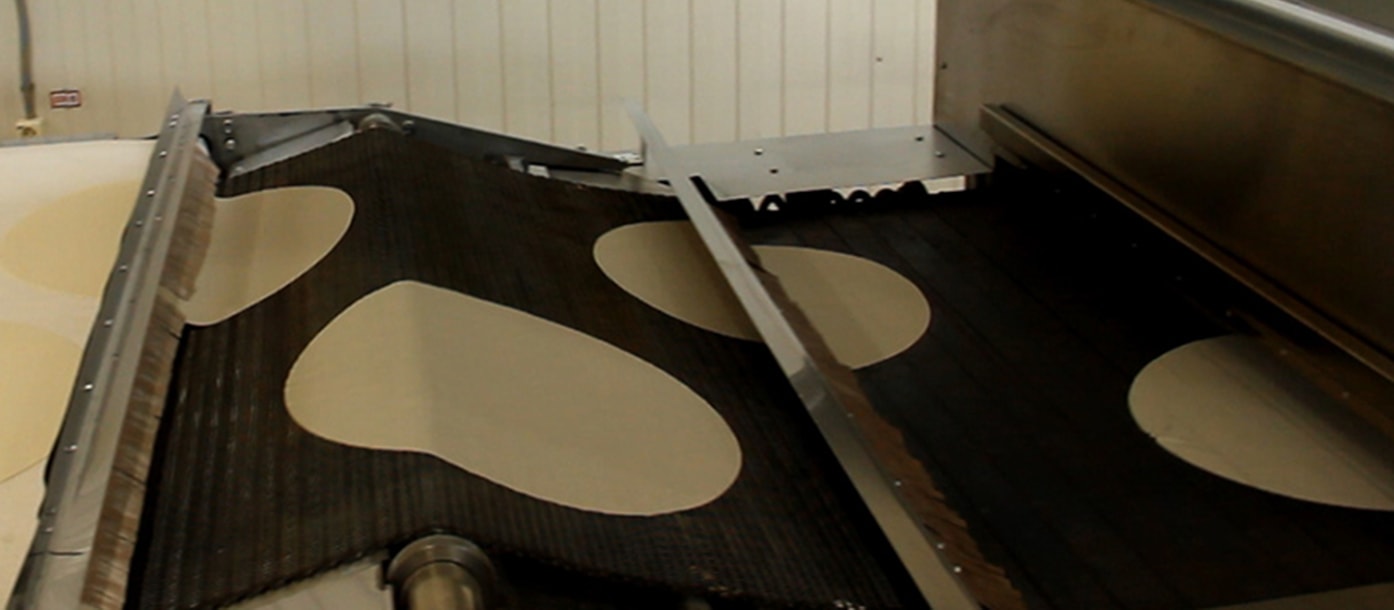

The equipment provides high and stable quality of lavash bread and a wide range of finished products – lavash of rectangular, square, round and oval shapes and various sizes as well as wheat rolls, etc.

In production of this line our company had invested more than 20 years of experience in designing and manufacturing of lavash equipment. The line implements a large number of new developments and unique technical solutions.

A 4-position knife unit with replaceable cutting drums is used in the line. The use of a unit with this design significantly shortens the time of shift from one type of product to another. In addition, the process of mounting and dismantling of drums became more convenient and the service life of the cutting edge of knives increased.

In the line AL-500 a unique high-speed track lavash oven with a length of 10 meters is used. In this oven compactness, high quality of lavash bread and high productivity are combined.

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H