Launch of the new automatic line for puff pastry production manufactured by UTF-GROUP

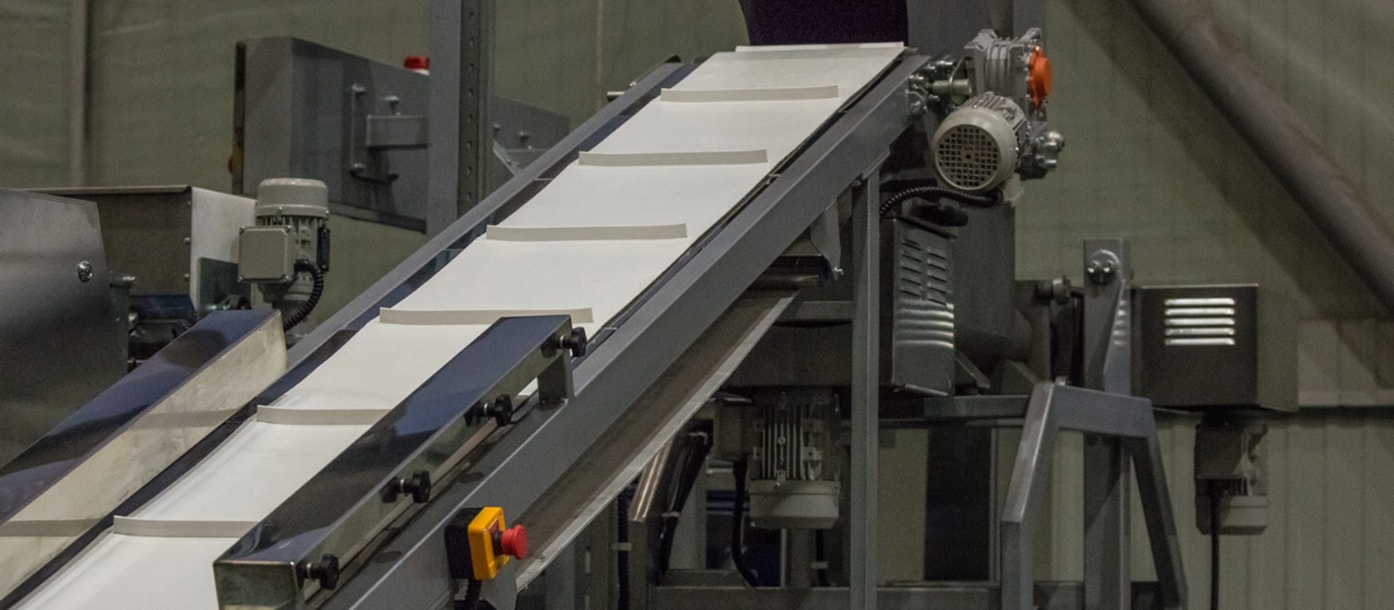

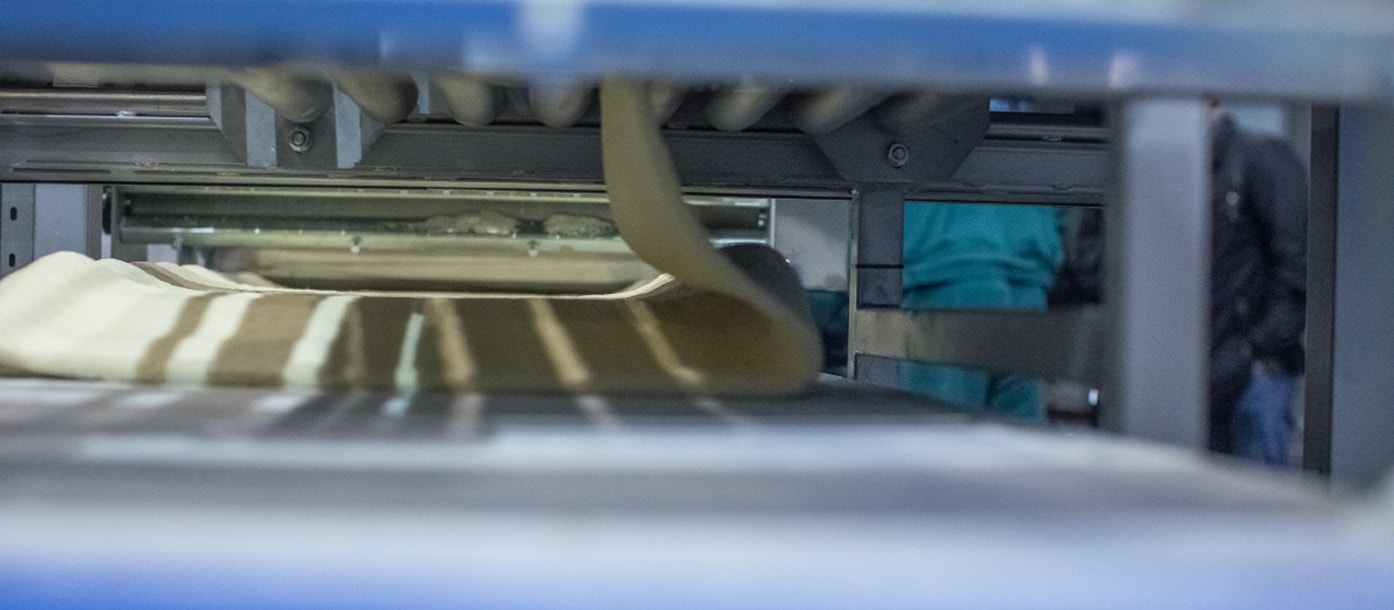

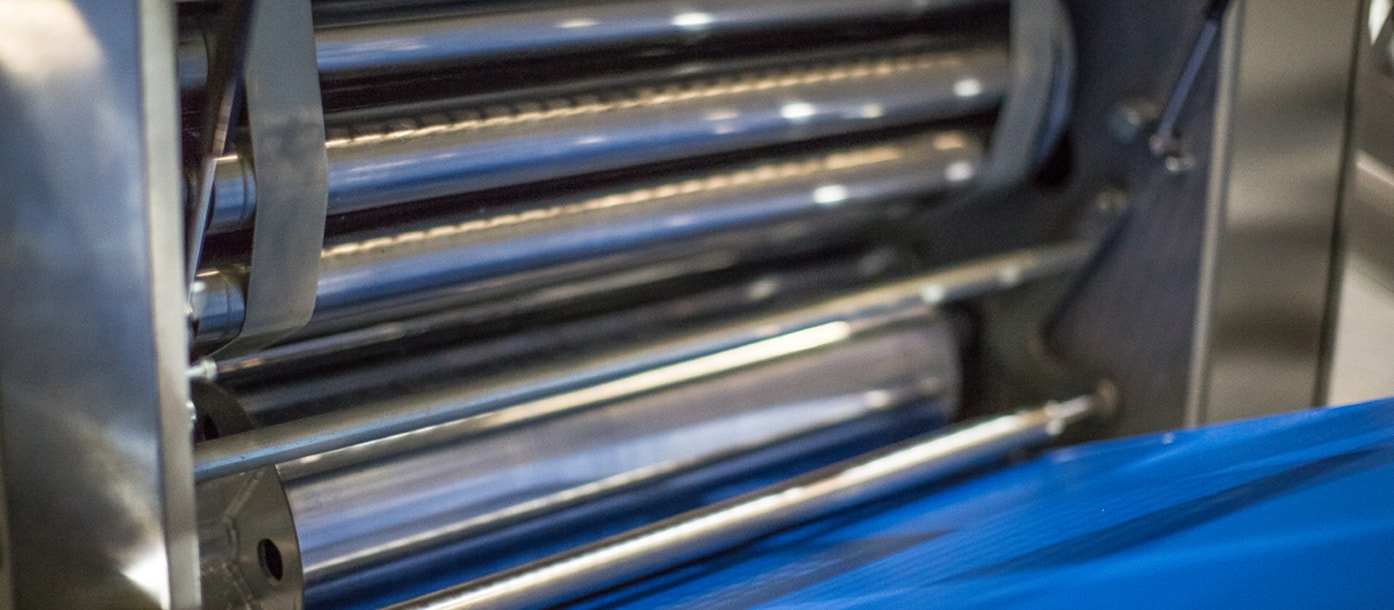

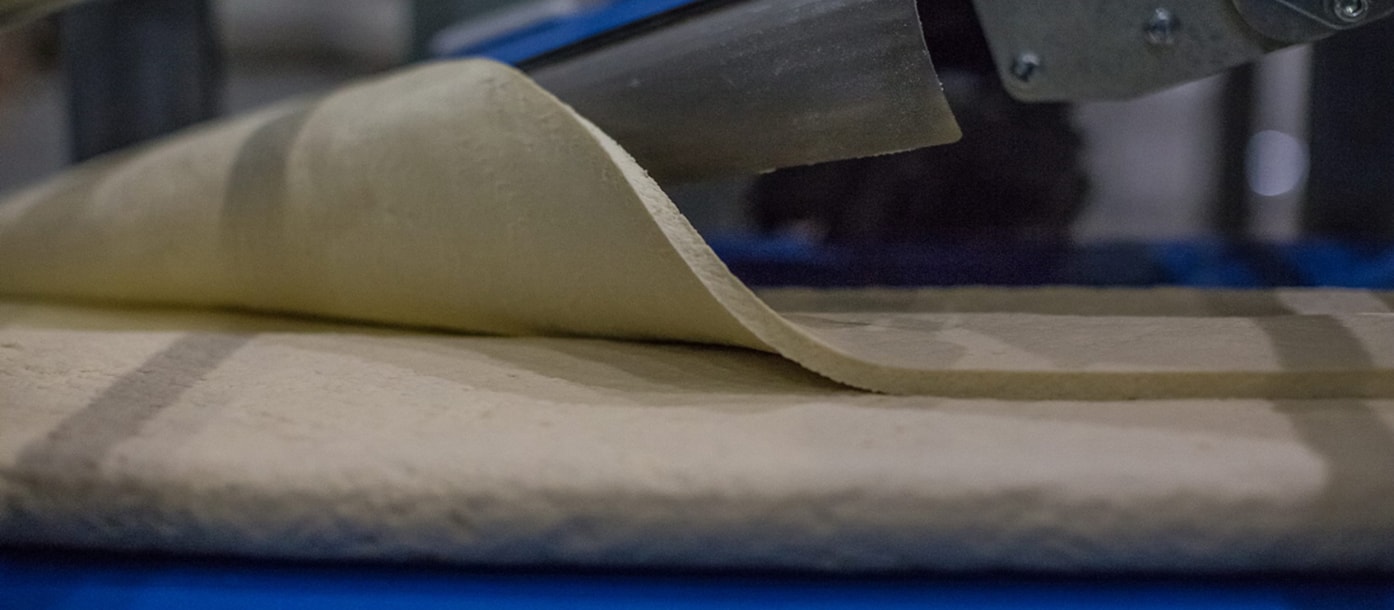

The comprehensive project for the organization of continuous production of puff pastry in automatic mode was realized by our company.

The line provides automatic production of up to 1000 kg/h of puffpastry dough, the number of layers in which is adjustable up to 288.

The line design allows the production of yeast puff pastry dough without the use of a cooling tunnel.The width of the conveyor at the exit of the line is 1000 mm, thickness of the ready puff pastry dough is from 2 to 6 mm.

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H