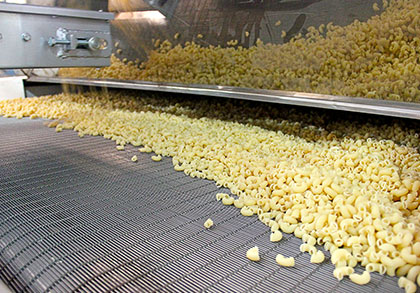

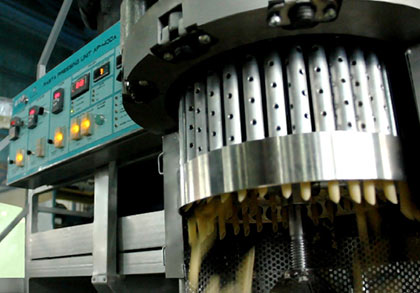

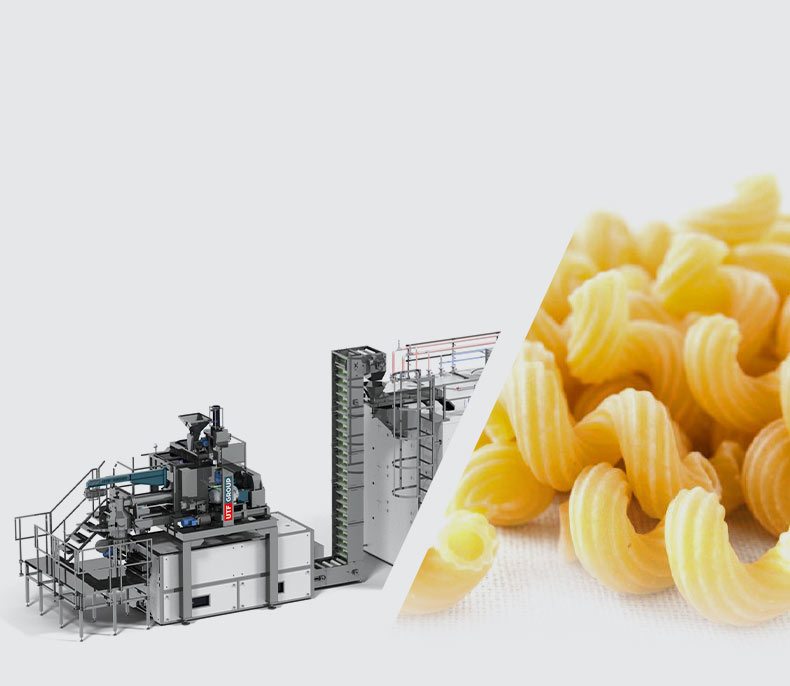

Випуск широкого асортименту макаронних виробів — вермішель, павутинка, ріжки, спіралі, труби, черепашки та багато інших. Макарони високої якості з відмінним смаком та привабливим зовнішнім виглядом виготовляються за італійською технологією. Виробництво як матових, і глянсових видів.

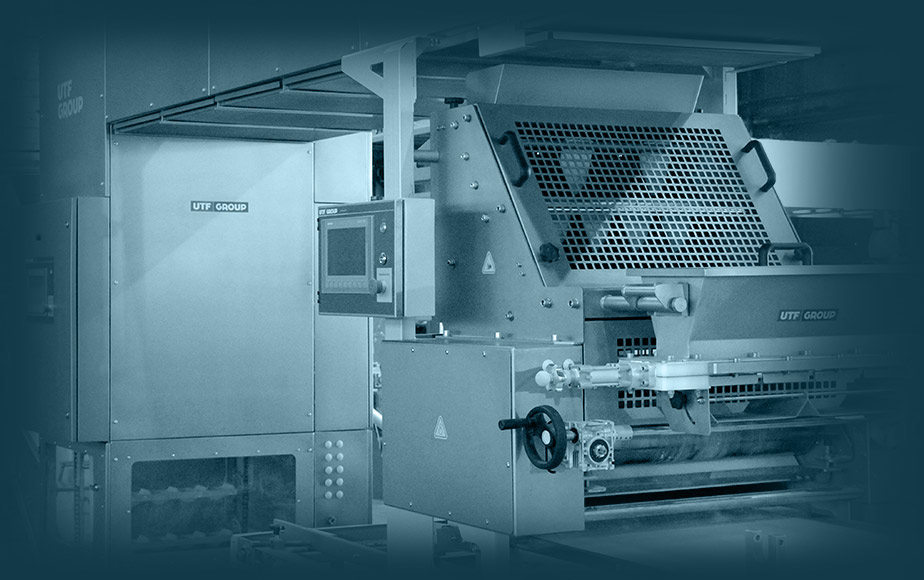

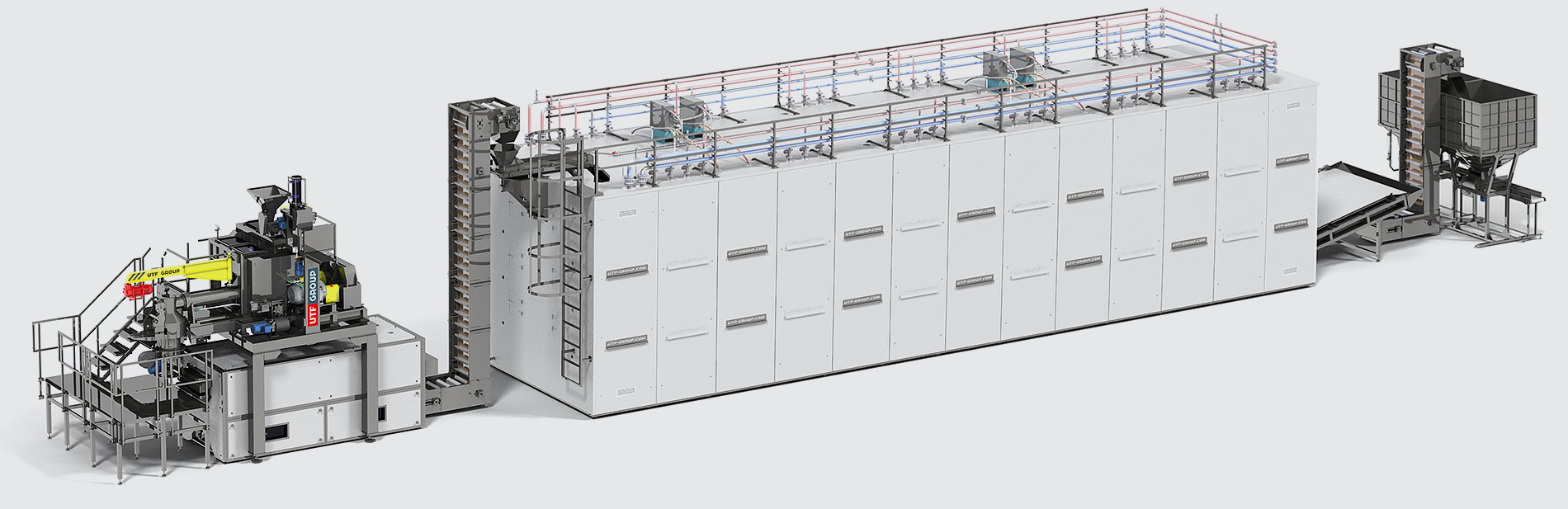

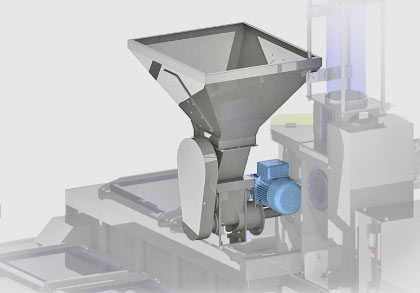

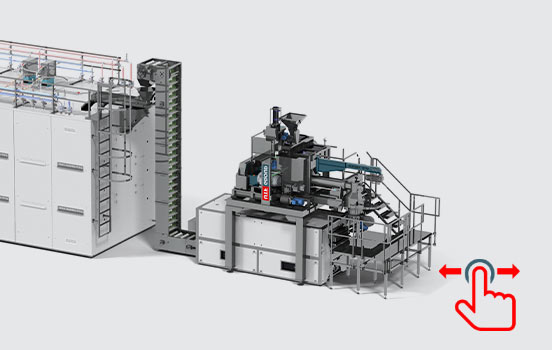

АВТОМАТИЧНА ЛІНІЯ

З ВИРОБНИЦТВА КОРОТКОРІЗАНИХ МАКАРОННИХ ВИРОБІВ

Продуктивність 250-1000 кг/год

Всі лінії виготовляються за індивідуальним замовленням, включають кращу електроніку, що управляє, і повністю протестовані на підприємстві.

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում