Швидкий перехід з одного продукту на інший за рахунок швидкознімної конструкції формуючих вузлів.

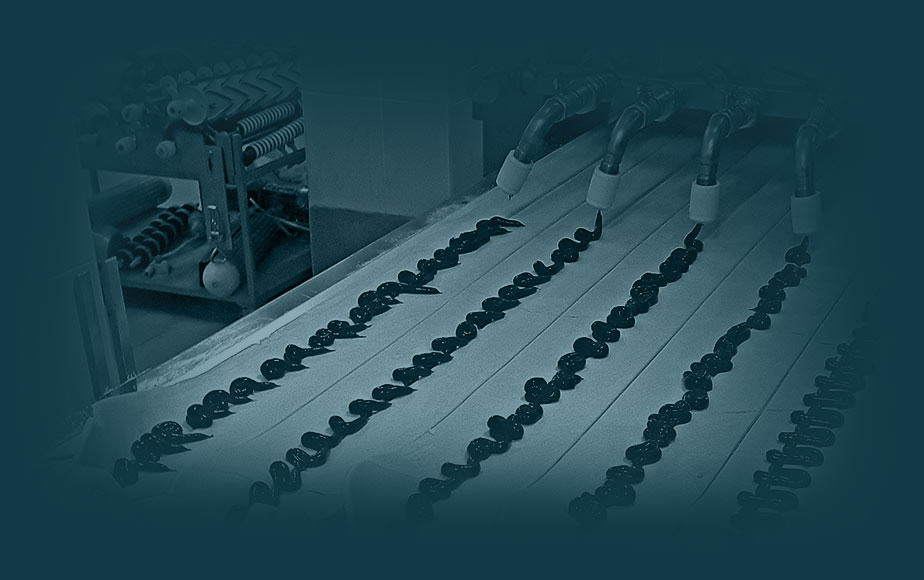

ЛІНІЯ ФОРМУВАННЯ ВИРОБІВ

З ЛИСТКОВОГО ТІСТА

Широкий асортимент кондитерських виробів з листкового тіста. Висока точність форми та ваги виробів. Відсутність потреби у кваліфікованих кондитерах. Компактні розміри обладнання.

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում