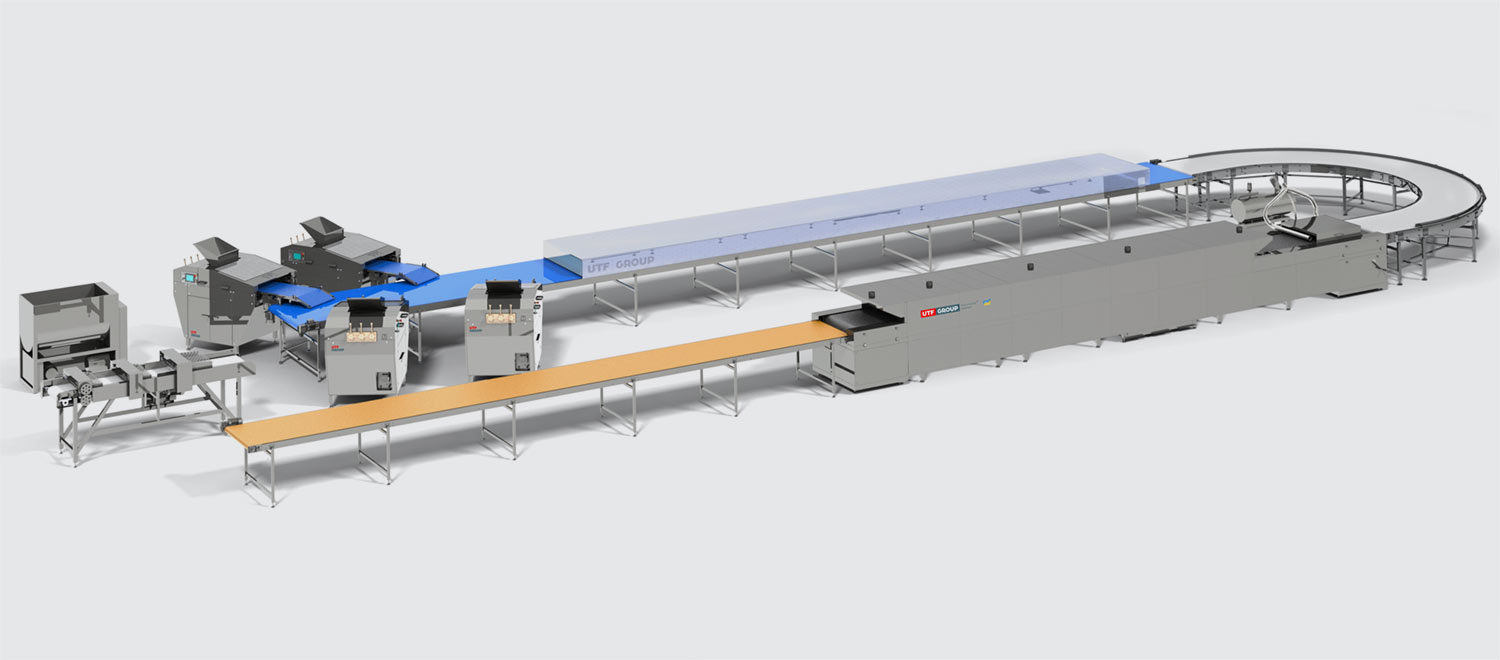

ТЕСТОПІДГОТОВЧЕ ОБЛАДНАННЯ

Забезпечує ефективний процес одержання тіста від дозування сировини до подачі готового тіста на ділянку формування заготовок.

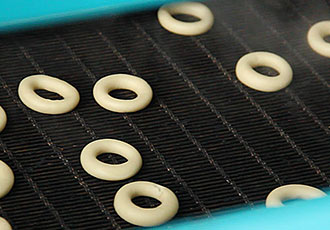

Виробництво всіх видів баранкових виробів

Мінімальна собівартість продукції

Високий рівень автоматизації

Висока точність форми та розмірів

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

ПРОДУКТИВНІСТЬ

100-250 КГ/ЧАС

ДОВЖИНА ПЕКАРНОЇ КАМЕРИ

ДО 30 М

ОБСЛУГОВУЮЧИЙ ПЕРСОНАЛ

3 ЛЮДИНИ

Забезпечує ефективний процес одержання тіста від дозування сировини до подачі готового тіста на ділянку формування заготовок.

Ущільнює тісто і видаляє з нього бульбашки повітря, для чого тісто кілька разів прокочується через прокатні валки із зменшенням зазору.

Ділильно-формуюча машина автоматично відокремлює порцію тіста і формує тестові заготівлі баранкових виробів, кількість машин залежить від продуктивності лінії.

Обробляє поверхневі шари заготівлі гарячою парою для створення блискучої глянсової поверхні готових виробів.

Випікає баранкові вироби на сітчастому поді у кількох температурних зонах

Забезпечує в автоматичному режимі подачу необхідної пари на камеру ошпарювання

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?