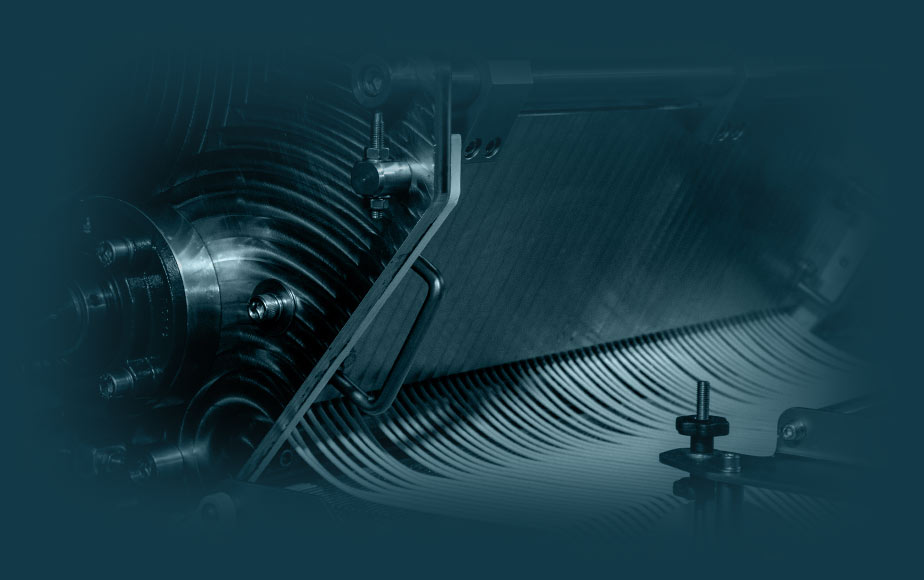

ФОРМУЮЧА МАШИНА СОЛОМКИ

формує джгути тіста заданого діаметра, які для виключення склеювання рівномірно розподіляються по ширині конвеєра

Продуктивність від 80 до 150 кг/год

Випуск соломки різних видів: солодкої, солоної, ванільної, київської.

Повна автоматизація процесу виробництва.

Продукт різної довжини та діаметру

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

ПРОДУКТИВНІСТЬ

100-250 КГ/ГОДИНУ

ДОВЖИНА ПЕКАРНОЇ КАМЕРИ

ДО 30 М

ШИРИНА ПОДА ПЕЧІ

1000-2000 ММ

ОБСЛУГОВУЮЧИЙ ПЕРСОНАЛ

2 ЛЮДИНИ

формує джгути тіста заданого діаметра, які для виключення склеювання рівномірно розподіляються по ширині конвеєра

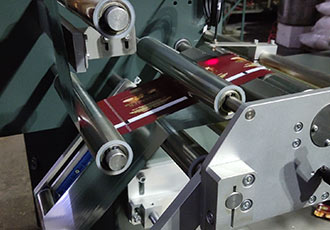

надає соломці золотистого відтінку, для чого джгути тіста пропускають через ванну з нагрітим до 70-90°С розчином двовуглекислого натрію.

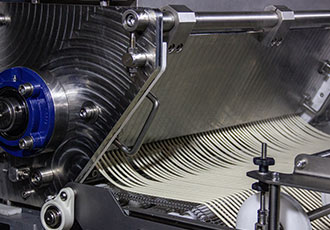

надсікає джгут тіста для формування майбутньої лінії надлому готового продукту, відстань між надсічками є довжиною соломки та регулюється системою керування

для розширення асортименту можливе посипання джгутів тіста сипучими компонентами (сіллю, маком, кунжутом і т.п.)

випікає соломку на сітчастому металевому поді в пекарній камері з кількома температурними зонами

охолоджує соломку після випікання на системі стрічкових транспортерів до температури пакування

Формуюча частина лінії виробництва соломки є окремим комплексом обладнання, що дає можливість спільної роботи з існуючими на підприємстві замовника тунельними печами з сітчастим подом.

Для автоматизації процесу пакування можливо забезпечити інтеграцію до складу лінії машин для пакування соломки в поліетиленові пакети, картонні ящики та інші види упаковки.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?