THE EQUIPMENT ENSURES

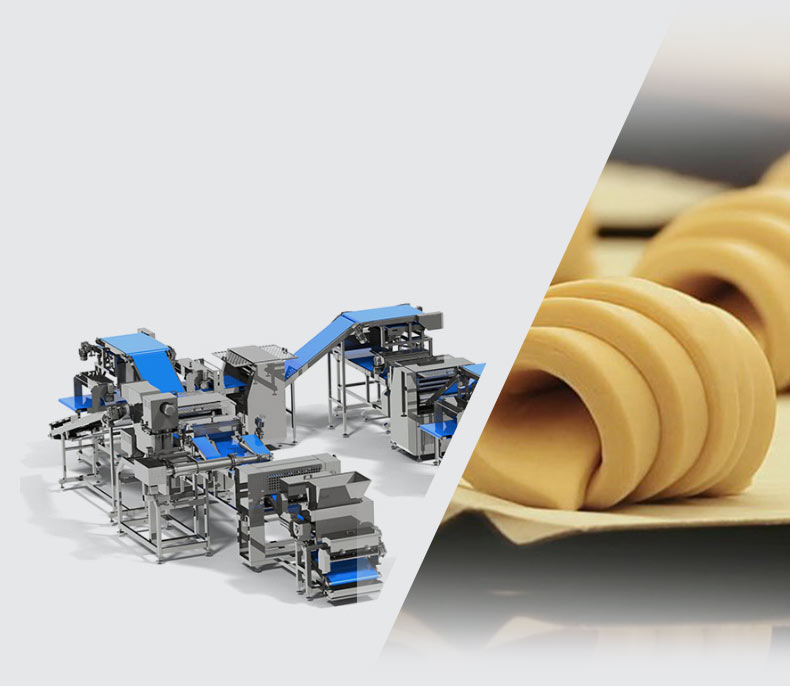

High production capacity, wide range of products, high precision of weight, shape and winding of the croissant, gentle processing of the dough while maintaining its ideal structure, product change within a few minutes

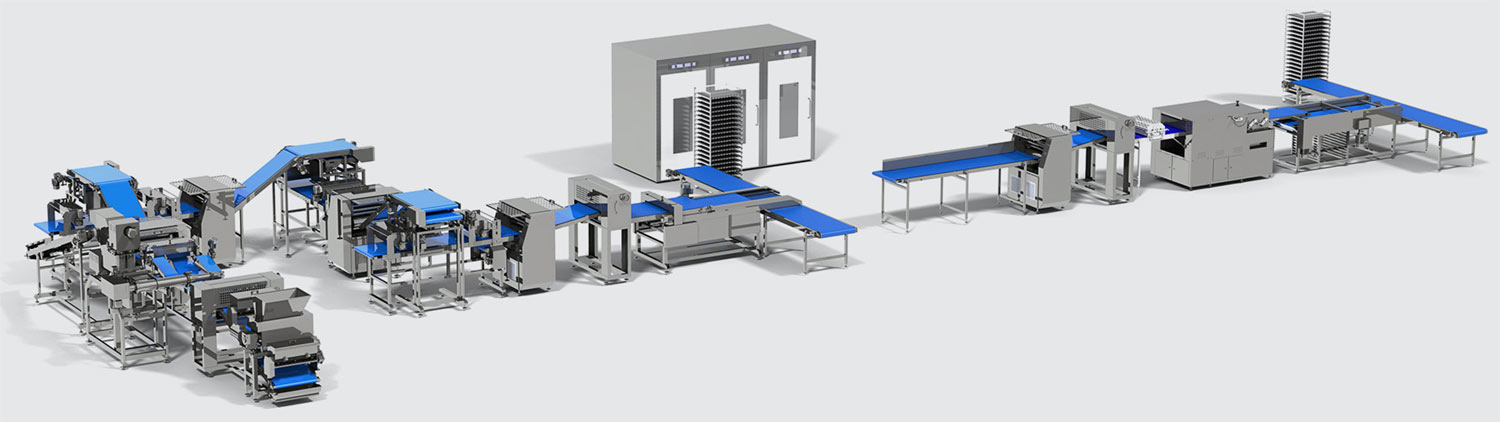

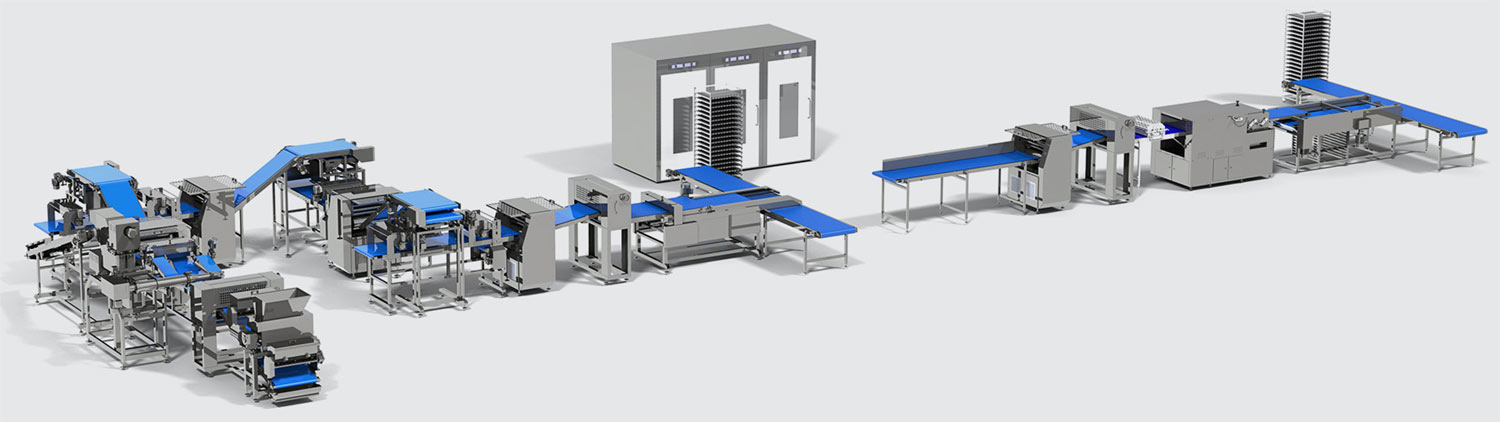

A large number of line options are created according to specific customer needs for production of a wide range of croissant size, shape and weight. Croissant with different types of bend may be formed: straight, curved, compressed and others. Automation of the main technological processes is implemented.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

CAPACITY

UP TO 4200 PCS/HOUR

NUMBER OF ROWS OF CROISSANTS

UP TO 7 ROWS

SERVICE STAFF

2 PEOPLE

High production capacity, wide range of products, high precision of weight, shape and winding of the croissant, gentle processing of the dough while maintaining its ideal structure, product change within a few minutes

It is possible to develop the project of a complete line for the croissant production which includes dough preparation, dough pieces forming, croissants baking, cooling and packaging.

To cool puff pastry dough, it is possible to use automatic conveyor chambers for complete automation of the process of croissant dough pieces forming.

The machine for filling, installed before forming machine, allows you to significantly expand the range of products.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?