DOUGH PREPARATION EQUIPMENT

It performs a complete technological process of dough obtaining from raw materials dosing to finished dough supplying to the section of blanks forming

Types: pita with a pocket, greek pita

We offer automatic production lines with different capacity from 2000 up to 15000 pieces per hour.

High capacity equipment works in continuous round the clock mode and ensures stable product quality.The line allows the production of various types of pita. Individual solutions are customizeds for each project.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

Capacity

from 2000 to 15000 pcs/h

PRODUCT DIAMETER

up to 210 mm

OCCUPIED AREA

≈ 150 m2

It performs a complete technological process of dough obtaining from raw materials dosing to finished dough supplying to the section of blanks forming

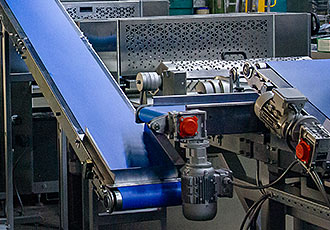

It forms a dough sheet and feeds it to the belt conveyor

It reduces the thickness of the dough sheet by multi-roll processing

It produces dough sheet of a given thickness for the subsequent blanks forming

They sprinkle the conveyor and dough surface with flour, which prevents the dough from sticking to the elements of the frame

Interchangeable cutting drums cut out blanks of a given diameter from the dough sheet

It removes scraps of dough sheet and supplyes it for reuse

It provides optimal conditions for dough proofing which significantly reduces the duration of the proofing process

It bakes the finished product on a metal track heart providing optimal conditions for the pita baking process

Cooling of the product on a long conveyor cooling system requires individual elaboration of the route at the customer’s premises

It lays out pita blanks on a cross conveyor to reduce oven length by increasing the width of the hearth or where room size is limited

Thanks to the system of conveyors it transports the dough scraps from the forming table directly to the extruder

To soften finished product it is passed through a curtain of sprayed water atomized by nozzles of humidifier

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?