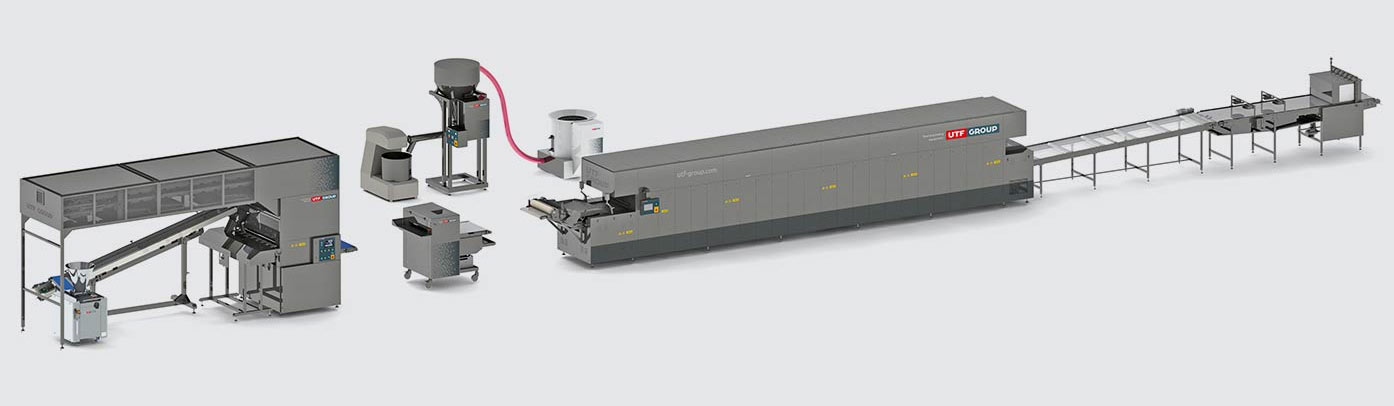

DOUGH SHEETING MACHINE FOR LAVASH

The dough piece is rolled out to the specified thickness.

Rolling is performed in two directions.

Capacity up to 100 kg/h

The line occupies small area but ensures high productivity. CE certificate for work in the European Union countries is provided.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

CAPACITY

100 KG/H

INSTALLED POWER

UP TO 75 KW

SERVICE STAFF

4 PEOPLE

EQUIPMENT AREA

FROM 75 M2

The dough piece is rolled out to the specified thickness.

Rolling is performed in two directions.

Loading conveyor with a press roller allows you to feed a thin dough piece of lavash to the hearth of the oven in automatic mode.

Several individually adjustable temperature zones ensure a consistently high quality of baking.

For Sevany lavash baking we produce gas or electric tunnel ovens. The selection of the oven is carried out taking into account capacity of the equipment and ensures maximum economic efficiency.

Nozzles form a water mist providing uniform moistening of the entire lavash surface with minimal water consumption.

The vacuum system separates dough portions with high precision and stability of the weight. The minimum pressure on the dough allows to work with liquid dough.

Automatic proofing of the dough is carried out in a conveyor chamber where optimal conditions are created for the process of dough fermentation. The design provides a minimum footprint.

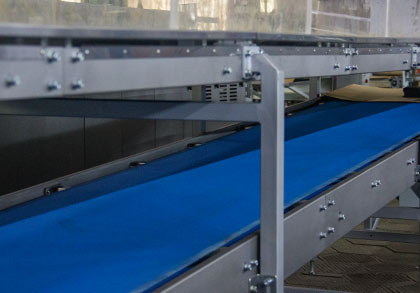

Lavash reaches normal temperature and humidity on the stabilization conveyor, evenly distributing moisture throughout the thickness of the product.

Qualified bakers are not required due to the automation of all critical technological processes

Reliable round-the-clock operation is ensured by the use of high quality materials and components

Automation of the processes for dough proofing, blanks forming and baking ensures the production of high quality lavash

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?