ОБЛАДНАННЯ ДЛЯ ФОРМУВАННЯ МАЦІ

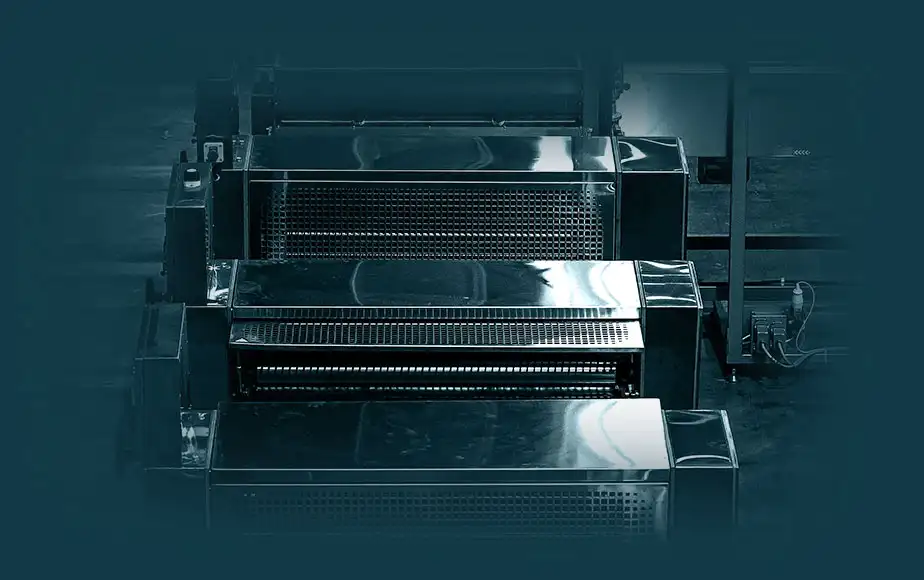

Формування заготовок виконується з каліброваної стрічки тіста. Стрічка формується валковим екструдером з поперечним розкладником, прокочується на тримодульній машині розкочування.

Продуктивність обладнання до 500 кг/год

Відповідає найжорсткішим вимогам, що висуваються при виробництві кошерної маци; формує тестову стрічку з ручною перевіркою перед розкочуванням; гарантує вільний прохід тесту без можливості застрягання по ходу руху.

Забезпечує високу швидкість руху та продуктивність; застосовує конструкцію печі, оптимізовану для випікання національних видів плоского хліба.

UTF-GROUP, один із найбільших виробників промислових ліній та обладнання для виробництва національних видів хліба у Східній Європі.

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Формування заготовок виконується з каліброваної стрічки тіста. Стрічка формується валковим екструдером з поперечним розкладником, прокочується на тримодульній машині розкочування.

Тісто надходить на ножовий конвеєрний стіл, де формуються заготовки.

Для випікання застосовується газова або електрична тунельна піч. Довжина та ширина печі підбираються в залежності від продуктивності лінії.

Після випікання маца охолоджується на конвеєрі охолодження, залежно від планування приміщення можуть застосовуватись поворотні, багатоярусні конвеєри або конвеєрні системи різного компонування.

повна автоматизація процесу виготовлення від подачі тіста до пакування

відповідність вимогам до машин для випуску кошерної маци

мінімальна собівартість одиниці готового продукту

простота управління та обслуговування лінії

постачання та встановлення обладнання по всьому світу

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?