DOUGH PREPARATION EQUIPMENT

The preliminary prepared sifted flour and heated water are fed into the mixer by means of automatic dispensers. Minimal contact time of water with flour is ensured.

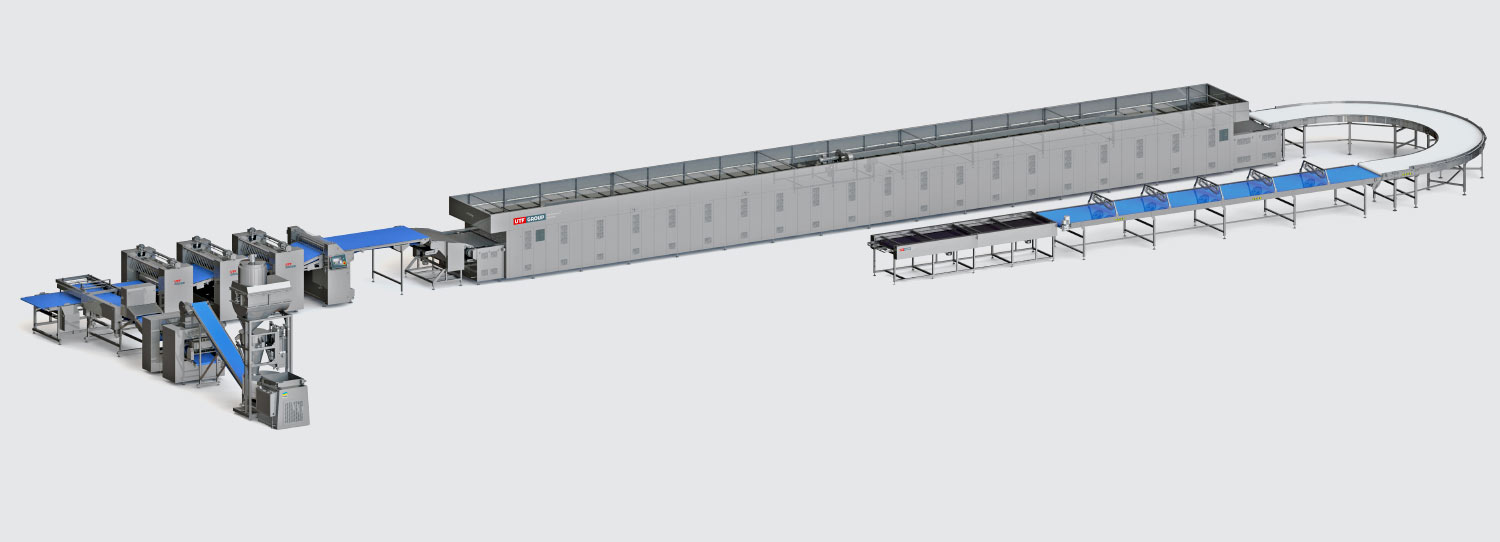

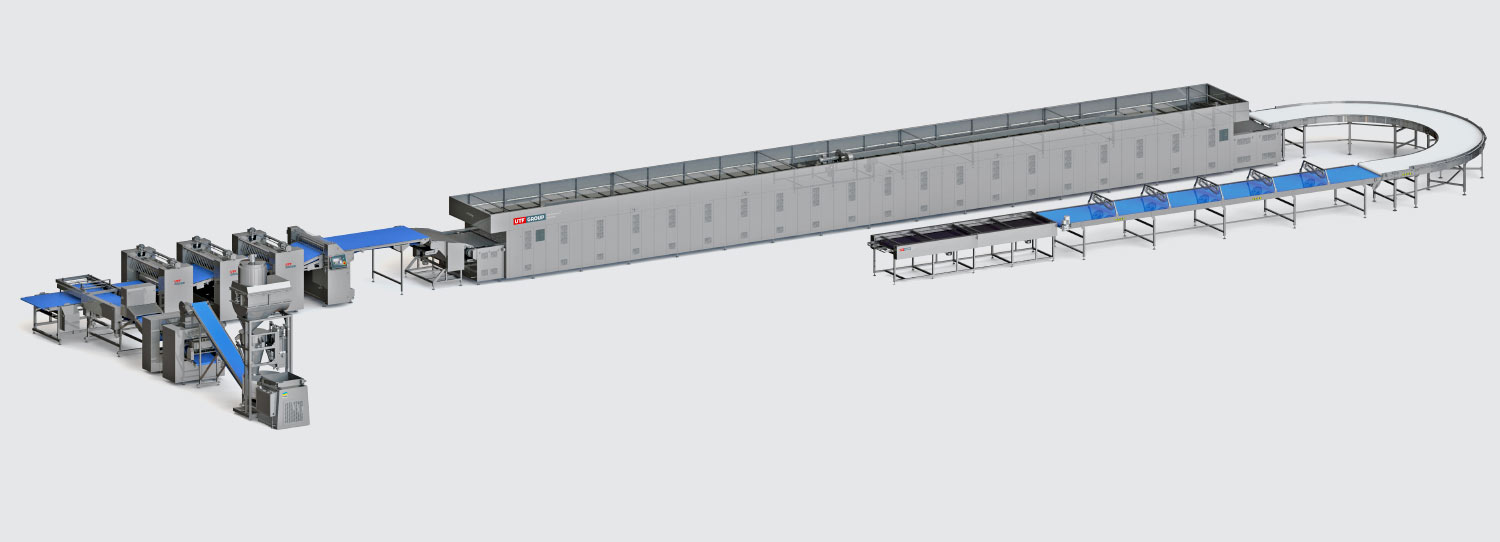

Capacity of the line 1000 kg/h

The line allows you to produce kosher matzos. The dough isn't delayed in the production process. The finished product production cycle is less than 18 minutes.

It ensures high capacity and automation of the entire process.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

CAPACITY

1000 kg/h

TIME OF BAKING

1.5 MIN

FINISHED PRODUCT

< 10 MIN

TEMPERATURE OF BAKING

380-400 °С

SERVICE STAFF

3 PEOPLE

The preliminary prepared sifted flour and heated water are fed into the mixer by means of automatic dispensers. Minimal contact time of water with flour is ensured.

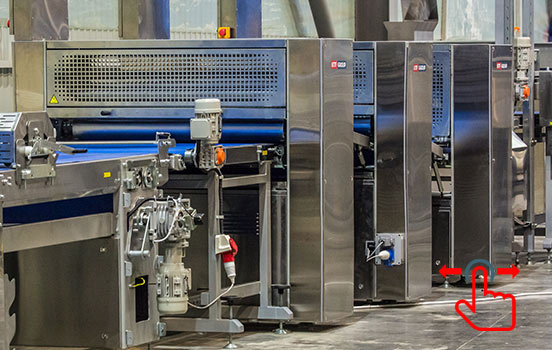

The roller extruder forms the matzo dough sheet, while the design of the hopper and rolling system eliminates dough delay.

It calibrates the dough sheet for thickness, eliminating the delay of the dough in the machine elements.

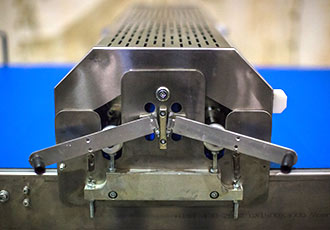

Cutting by guillotine of dough sheet fragments of equal length and their transverse laying in several layers allows you to create the necessary structure of the dough.

It rolls out the dough to obtain the dough sheet of the required thickness. The design of the machine eliminates the dough delay in the equipment elements.

The disc cutting system separates the dough sheet into strips of a given width, with the dough perforated by a special block. Sticking of the dough in the units is excluded.

The final formation of matzo dough pieces is performed by a cross-cutting unit, which separates the dough strips into pieces of a given length.

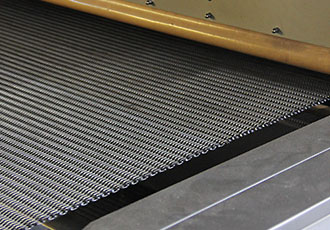

Metal mesh belt conveyor can handle the hot elements of the tunnel oven. It performs automatic stacking of matzo blanks on the mesh hearth of the oven.

It bakes matzos on a metal mesh hearth in a baking chamber with several temperature zones with individual heat control for an optimal and fast baking process.

The finished matzos have to be cooled after baking to room temperature. The design of conveyors system takes into account the layout of the premises and packaging equipment.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?