Automatic line with the capacity 400 kg/h has been launched in India

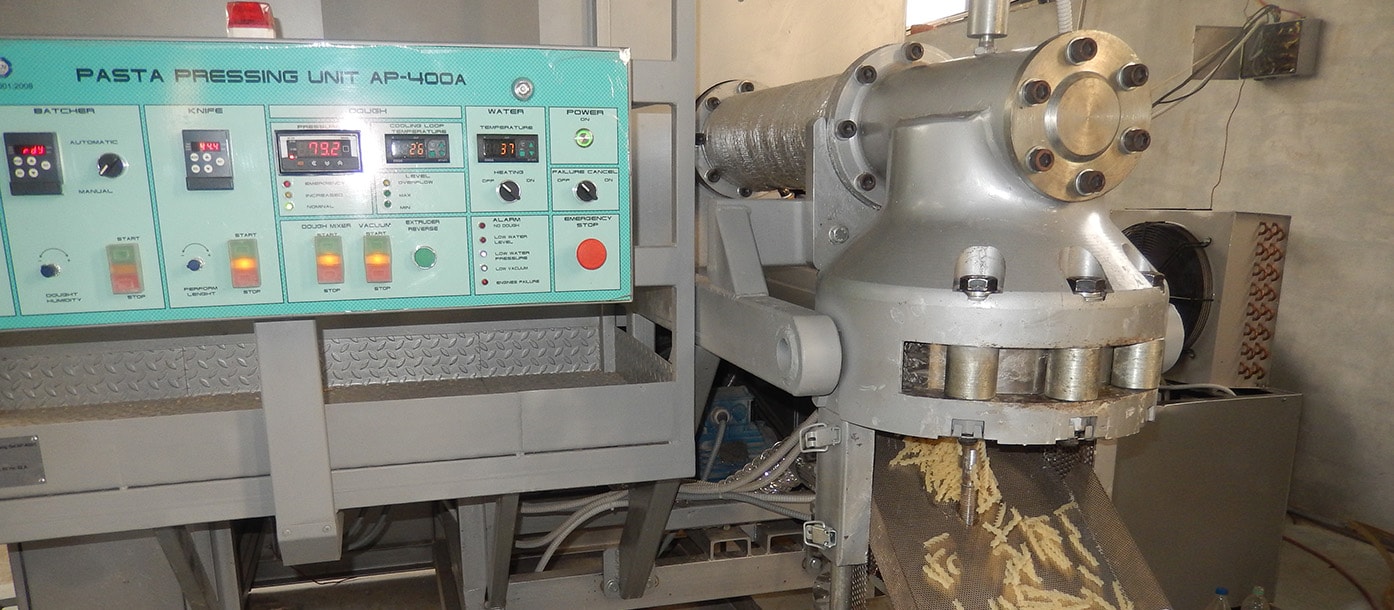

The complex of equipment for the automatic production of short-cut pasta made of durum wheat flour with a capacity of 400 kg/h was launched in the Indian city of Kanpur (Uttar Pradesh).

The complex was designed specifically for the implementation of this project. It includes:

-flour sifter-batcher with a bag tilting device;

-automatic pasta press;

-feeding conveyor systems;

-drying complex;

-steam processing system;

-cooling conveyor.

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H