EQUIPMENT FOR DOUGH PREPARATION

It is specially designed for the production of national types of bread and includes equipment for dough components dosing and mixing

Production of a number of lines with production capacity range from 500 to 2400 pcs/h.

It is traditional pita production technology with double dough proofing in automatic mode. Equipment works in 24/7 mode. Solutions are customized for each project.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

CAPACITY

1200, 2400 KG/HOUR

product diameter

up to 300 mm

It is specially designed for the production of national types of bread and includes equipment for dough components dosing and mixing

It separates portions of dough of a given weight with high accuracy to ensure the same size for the finished pita

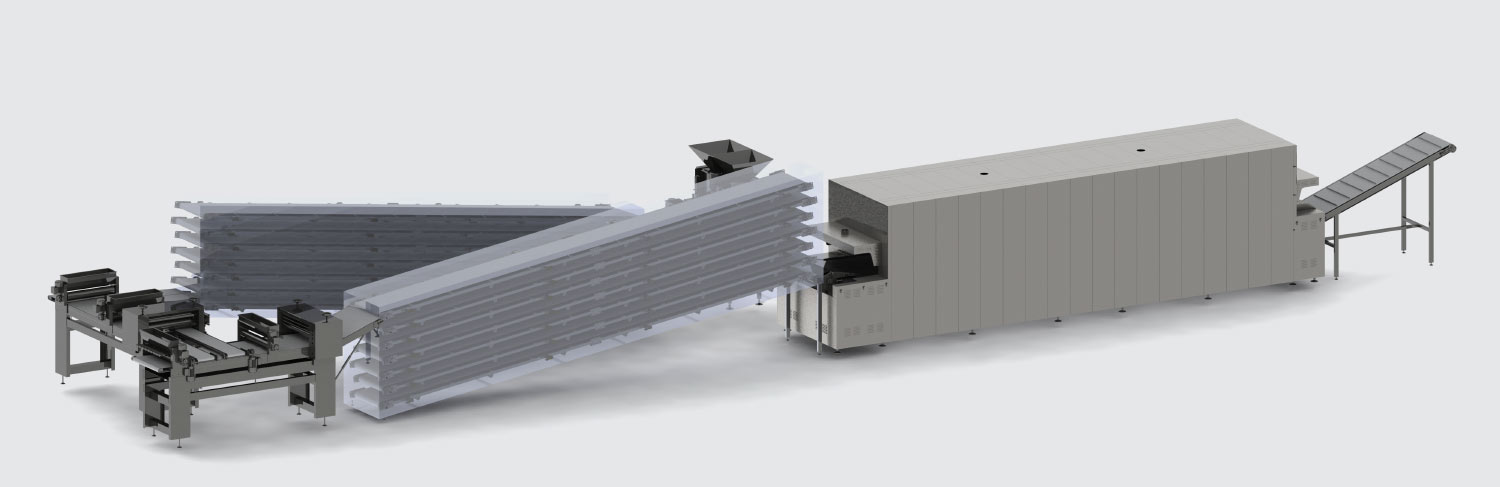

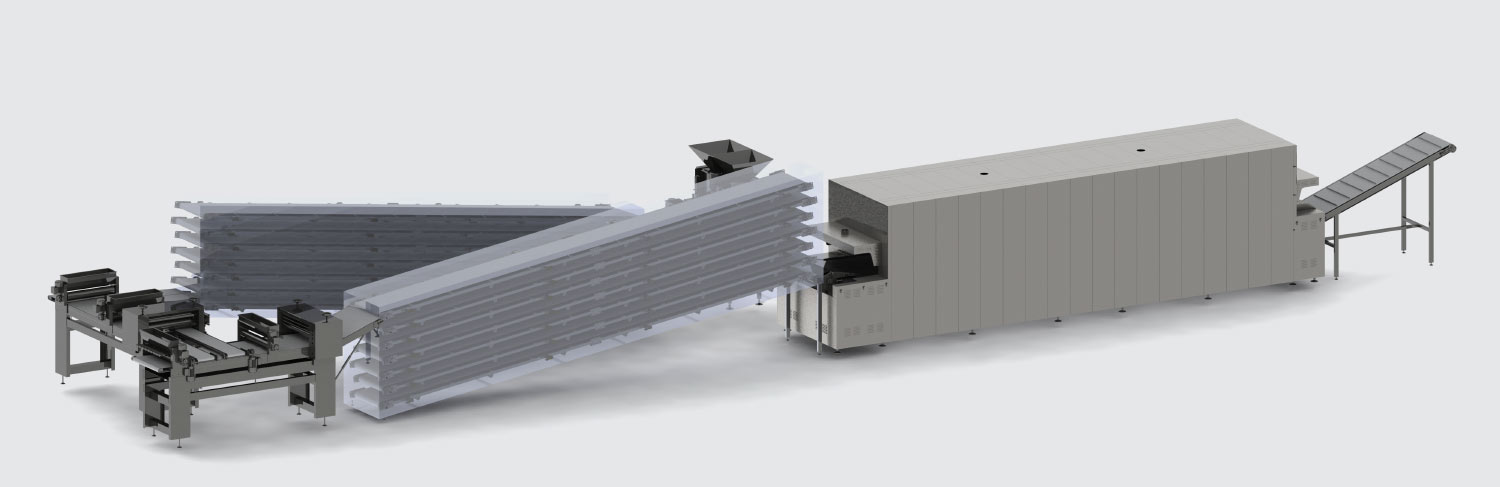

of dough portions is carried out on a multi-tiered conveyor of the proofing chamber

To obtain pita dough blanks, the rolling of dough portions is carried out on two sheeting machines, in two directions

Obtained dough blanks are proofed on a multi-tiered conveyor of the proofing chamber

Being specifically developed for baking national types of bread it provides optimal conditions for pita bread baking

Finished pita is cooled to the packaging temperature on the conveyor system with natural or forced cooling

Cooling of pita at high production volumes requires long conveyors of the cooling system. To reduce the space it occupies, it is possible to use multi-tiered spiral conveyors.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?