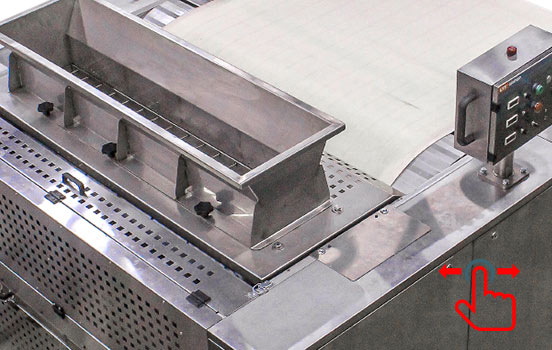

РОТОРОФОРМУЮЧА МАШИНА

призначена для формування заготівель начос формуючими барабанами та їх укладання на коневеєрну стрічку

Повністю автоматичний цикл приготування начос із кукурудзяного борошна.

Модульна конструкція для оптимальної організації виробництва.

Широкий асортимент форм, розмірів та смаків готових виробів.

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

ПРОДУКТИВНІСТЬ ЛІНІЙ

ВІД 90 ДО 500 КГ/ГОДИНУ

ОБСЛУГОВУЮЧИЙ ПЕРСОНАЛ

2 ЛЮДИНИ

ЗАЙМАНА ПЛОЩА

ВІД 160 М2

призначена для формування заготівель начос формуючими барабанами та їх укладання на коневеєрну стрічку

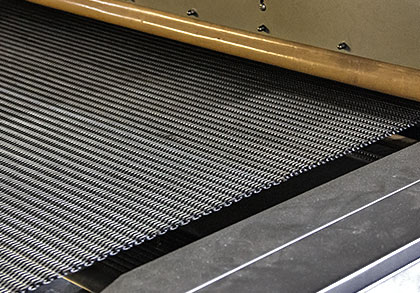

призначена для підсушування поверхні начос для збереження їх форми у процесі приготування в масляній ванні

конвеєр призначений для охолодження чіпсів після печі перед наступними операціями: обсмажуванням, внесенням спецій та упаковкою готового продукту

призначена для смаження начос повним зануренням на певний час у ванну з нагрітою до високої температури маслом

призначений для отримання начос з різними смаками внесенням суміші спецій, які рівномірно розподіляються по товщі продукту в барабані, що обертається

Комплект оборудования для приготовления никстамализованной кукурузной муки (масы) включая варочные котлы, ёмкости для выстаивания, моющую машину и мельницу для измельчения зерен

тунельні печі для підсушування та конвеєрні фритюрниці для смаження начос виробляються у двох варіантах – електричному та газовому

системи фільтрації та повторного використання олії, додаткові баки, системи автоматичної підтримки рівня олії, системи видалення крихти з масляної ванни

можлива комплектація лінії одно- та багатопотоковими пакувальними машинами для автоматичного фасування начос порціями заданої ваги

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?