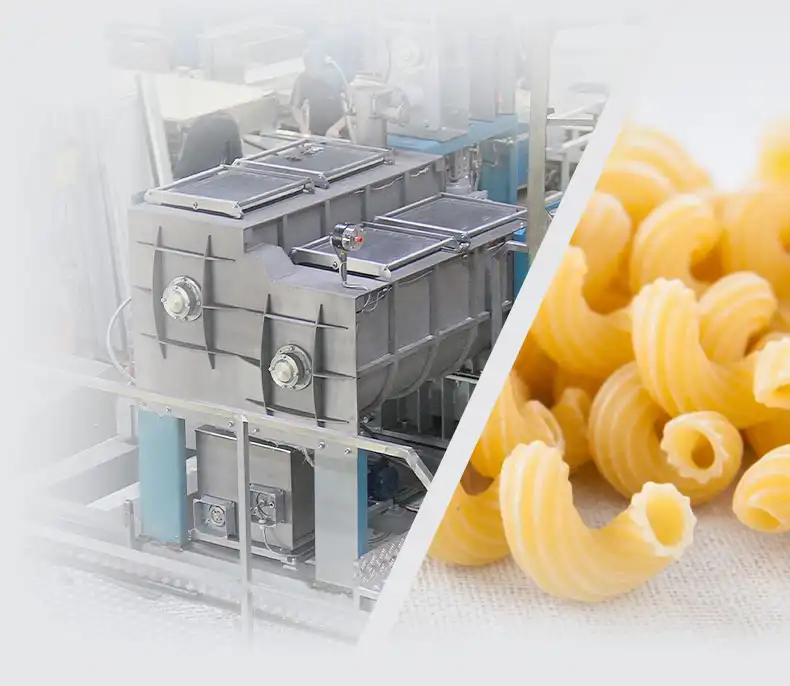

UTF GROUP ГАРАНТУЄ ВИРОБНИЦТВО МАКАРОН ВИСОКОЇ ЯКОСТІ

Отримання якісних макаронних виробів є складним технологічним процесом. Існує безліч технологічних тонкощів, що визначають якість на всіх етапах виробництва: від підготовки тесту до стабілізації готових виробів.

Високошвидкісне змішування на вході забезпечує ідеальну гідратацію сировини, повністю зволожуючи кожну частинку борошна.

Заміс макаронного тесту виконується за умов вакууму отримання високої якості готової продукції. При цьому, крім видалення повітря та ущільнення тіста, покращується склоподібність виробів та зменшується шорсткість, не відбувається потемніння тіста.

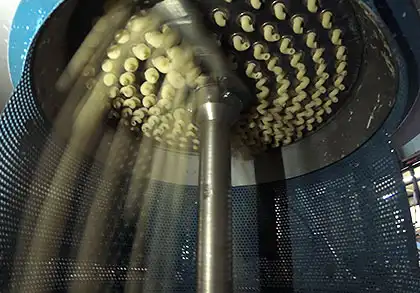

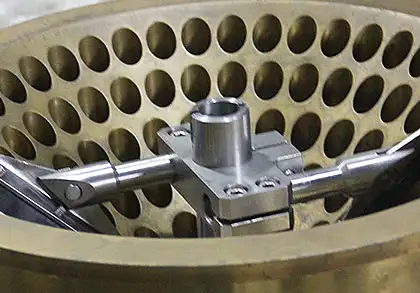

Установка фільтрувальної сітки та індивідуальних для кожної матриці колосників забезпечує правильну форму та довжину макаронів.

Застосування італійської низькотемпературної технології сушіння з делікатним видаленням надлишкової вологи дозволяє уникнути поява тріщин під час виробництва товстостінних макаронних виробів.

МАКАРОННЕ ОБЛАДНАННЯ UTF GROUP

— тривалий термін служби

— робота у будь-яких кліматичних умовах

— низькі експлуатаційні витрати

— високий ступінь енергозбереження

— відповідність європейським вимогам безпеки та гігієни

— виконання монтажних та пуско-налагоджувальних робіт у будь-якій точці світу

— постійну сервісну підтримку з цілодобовим каналом зв’язку

— навчання персоналу безпечної та ефективної роботи на лінії

— безкоштовні консультації з питань експлуатації та розширення можливостей обладнання

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում