ТЕСТОПІДГОТОВКА

Автоматична подача та дозування борошна та води для автоматизації процесу отримання тесту.

Продуктивність до 250 кг/год

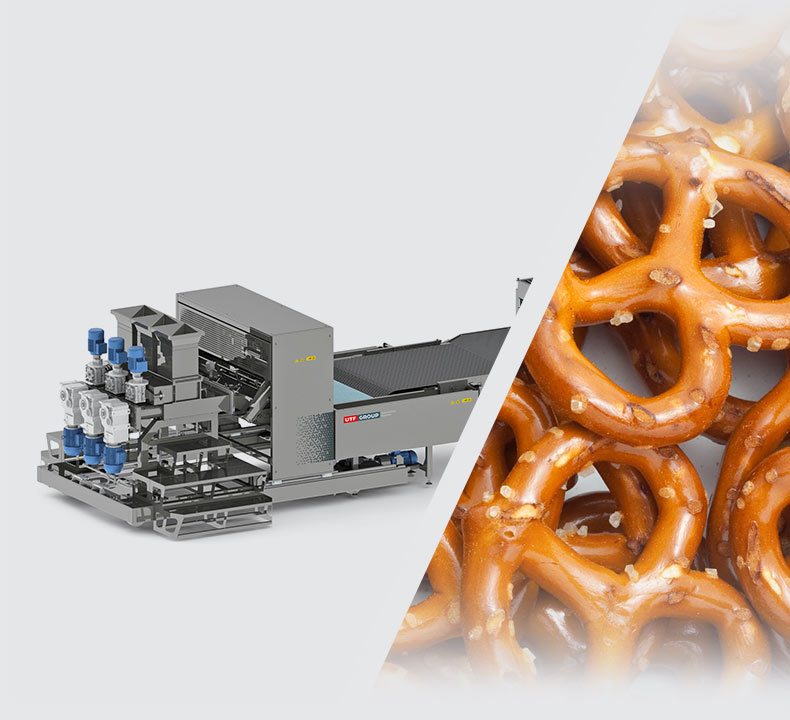

Широкий асортимент продукції на одній лінії.

Екструзійні головки зі змінними вузлами дозволяють випускати всі вироби на одній машині.

Система ошпарювання виробу надає блиску та насиченого відтінку готовим виробам.

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Продуктивність

До 250 кг/годину

Обслуговуючий персонал

2 людини

Займана площа

Від 150 м2

Режим експлуатації

Цілодобово

Автоматична подача та дозування борошна та води для автоматизації процесу отримання тесту.

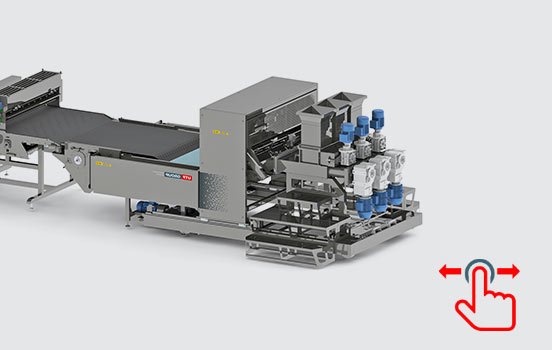

Шнековий екструдер зі змінними формуючими матрицями та пристроєм різання для виготовлення широкого асортименту снеків.

Обробляє поверхневі шари заготівлі гарячою парою для створення готових виробів з блискучою глянсовою поверхнєю.

Випікає снеки на сітчастому металевому поді у пекарній камері з кількома температурними зонами.

Надає снекам золотистого відтінку, для чого вироби пропускають через ванну з нагрітим розчином соди.

Для розширення асортименту можливе посипання виробів сипучими компонентами (сіллю, маком, кунжутом і т.п.)

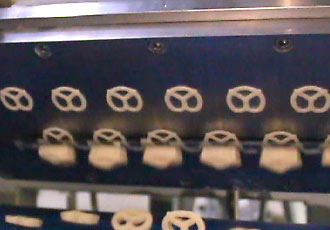

Шнекові екструдери низького тиску, що застосовуються в лінії, зберігають структуру тіста, що дає можливість надавати готовому виробу більш пористу і тендітну структуру.

Швидкозмінні матриці та зручний доступ вузлів формування прискорюють процес переходу з випуску одного виробу на випуск іншого.

Залежно від необхідної продуктивності можливе встановлення одного або кількох паралельно працюючих формуючих вузлів.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?