ОТРИМАННЯ СТРІЧКИ ТІСТА

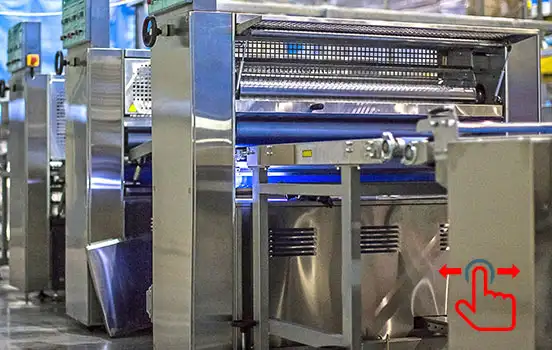

Тістова стрічка для отримання листкового тіста формується на валковому екструдері та доводиться до необхідної товщини на калібраторі.

Широкий діапазон обладнання та комплексів для виробництва листкового тіста та кондитерських виробів з нього. Від «язичків» та листкового печива до круасанів з різними начинками та тортів на основі листкових коржів.

Максимальна автоматизація виробничого процесу, можливість роботи з дріжджовим та бездрожжевим листковим тістом, випуск продукції за сучасними споживчими стандартами, сучасний дизайн та ергономіка.

UTF GROUP - український виробник, розробник та проектувальник обладнання для харчової промисловості з досвідом понад 25 років.

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Тістова стрічка для отримання листкового тіста формується на валковому екструдері та доводиться до необхідної товщини на калібраторі.

Екструдер жиру рівномірно укладає шар жиру на тестову стрічку, після чого стрічка згортається спеціальними вузлами поверх жирового прошарку.

Безпосередньо формування багатошарової структури проводиться машинами поперечного укладання. Комплектність лінії та конструкція машин залежать від необхідної кількості шарів.

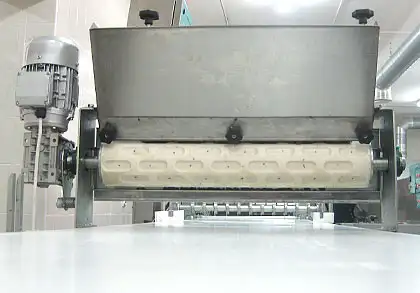

Після кожного етапу ламінації мультиролер виконує делікатну прокатку отриманої листкової тістової стрічки із збереженням отриманої структури тіста.

Формування заготовок із листкового тіста виконується набором вузлів та машин для згортання, скручування, дво- та багатошарового укладання, нанесення насічки на поверхню тощо.

Декорування виробів із листкового тіста проводиться набором машин та вузлів для подачі рідких та пастоподібних начинок, посипання сипучими компонентами, нанесення рідких та пастоподібних покриттів тощо.

Отримані заготовки виробів із листкового тіста випікають у печах кондитерських різних типів. Для високопродуктивного виробництва оптимальним вибором є кондитерські тунельні печі.

Для виготовлення круасанів застосовується спеціальна машина формування круасанів — круассаномат, який вирізує із тестової стрічки та згортає тістові заготовки круасанів.

Обладнання може працювати як у вигляді самостійних одиниць, так і у складі автоматичних комплексних ліній для повного циклу виробництва листкових виробів від отримання тіста до упаковки готових виробів.

Спеціальний конвеєр забезпечує рівномірну подачу порцій жиру в екструдер. Це дає можливість зменшити персонал, замінивши безперервний контроль подачі жиру періодичним з боку оператора лінії.

Завдяки великому вибору змінних формуючих та декоруючих вузлів наша промислова кондитерська машина для листкових виробів забезпечує випуск широкого асортименту готових виробів із листкового тіста.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?

Ніжний смак листкового тіста та найширші можливості для його застосування давно привертають увагу як кондитерів, так і любителів солодкого.

Кондитерські вироби з листкового тіста виробляють багато підприємств від невеликих пекарень до великих кондитерських виробництв. Ручне виготовлення потребує високої кваліфікації кондитера. Тому при зростаючому обсязі виробництва потрібно обладнання для листкового тесту з різним ступенем автоматизації.

Отримання листкового тесту є дуже трудомістким і складним технологічним процесом. Як правило, за невеликих обсягів виробництва його отримують вручну або використовують готове заморожене тісто. Автоматичне формування стає затребуваним тільки в тому випадку, якщо підприємство виробляє великий обсяг листкових кондитерських виробів або великі партії замороженого листкового тесту.