FLOUR TORTILLA

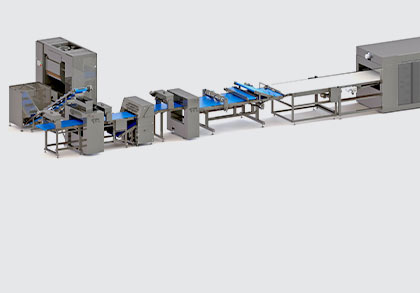

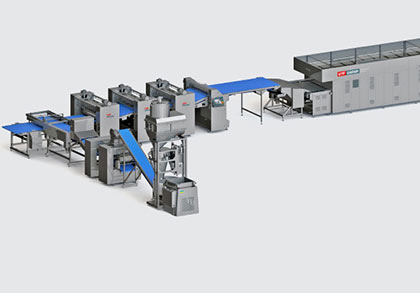

Our company produces separate machines and automatic lines for flour tortilla production with a capacity from 100 up to 600 kg/h

We produce flatbread making machines, fully automatic industrial lines and other solutions for the production of various flat bread types: lebanese bread, lavash, pita, corn and flour tortilla, israeli matzo, papad, chapati and others - processing equipment for the production of various flatbreads

Our commercial equipment ensures all processes of flatbread production.

We have: pita bread production lines, flour tortilla equipment, commercial corn tortilla machines, arabic bread machines, lavash production lines, matzo production equipment suitable for any business size

UTF GROUP is a manufacturer of fully automatic flatbread machines with more than 25 years of experience in food processing equipment

UPGRADE YOUR PRODUCTION WITH UTF GROUP

Our company produces separate machines and automatic lines for flour tortilla production with a capacity from 100 up to 600 kg/h

There are commercial corn tortilla machines and turnkey solutions for corn tortilla production with a capacity up to 500 kg/h

We also produce fully automatic lines fo thin pita (arabic pita bread) production up to 30 cm diameter with capacity up to 2400 pcs/h

We also produce fully automatic lines fo thin pita (arabic pita bread) production up to 30 cm diameter with capacity up to 2400 pcs/h

We hold leader position in the development and production of industrial processing equipment for lavash production. Our company developes lavash machines and lines with a capacity from 20 up to 500 kg/h

There are industrial automatic equipment for israeli matzo production with a capacity up to 1000 kg/h

It ensures all processes of pita production including dough preparation, proofing, forming, cutting, baking and cooling.

We hold leader position in the development and production of industrial processing equipment for lavash production. Our company developes lavash machines and lines with a capacity from 20 up to 500 kg/h

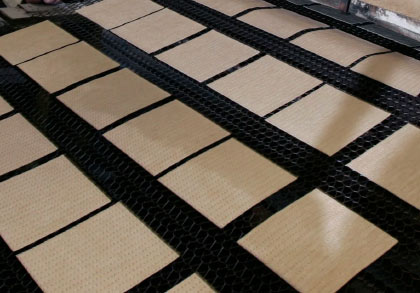

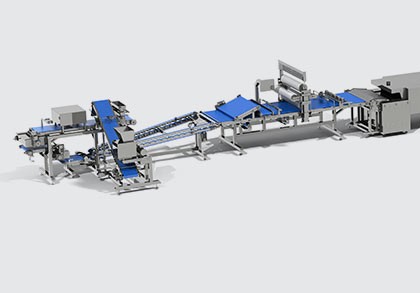

Automatic line for the production of corn tortillas with capacity up to 500 kg/h

The fully automatic industrial tortilla machines allow to produce tortillas with a diameter up to 300 mm

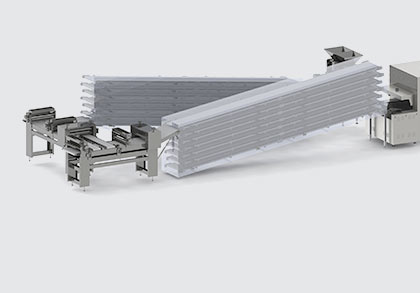

Automatic and semi-automatic lines for small, medium and large business with various caapacities. Choose the equipment: 500, 300 , 200, 100, 80, 30 (kg/h)

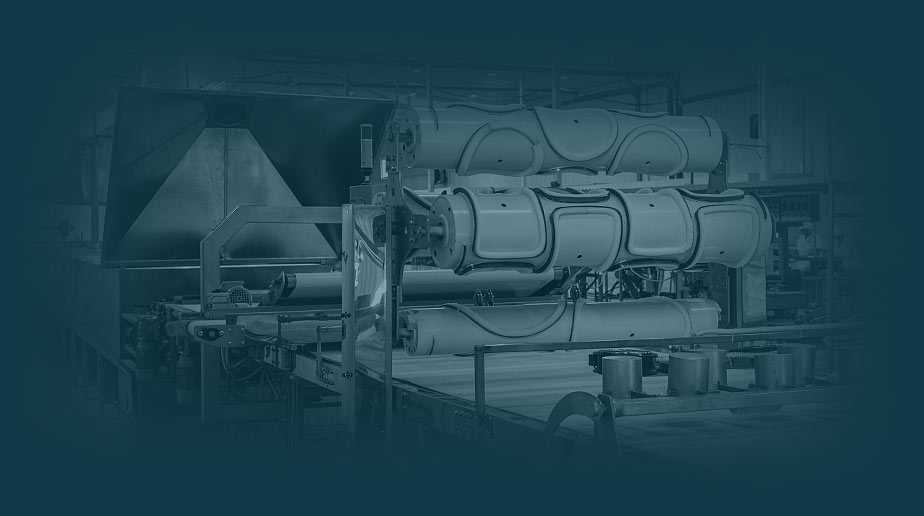

Automatic line for the production of israeli matzo with capacity up to 1000 kg/h

Screw dough divider with several rows, rounding units, heated pneumatic presses.

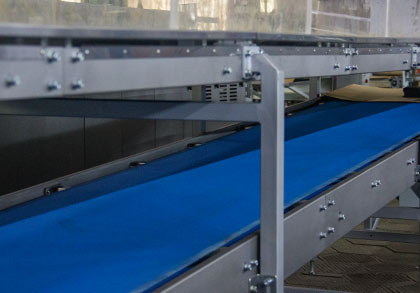

Molding forming machine ensures forming of corn tortilla blanks by molding drums and their laying on a conveyor belt.

Rolling machines form dough blanks by sequential rolling in two perpendicular directions. Another technology for pita production consits in cutting out dough blanks from dough sheet.

Dough extruders, dividers, rounding units, rolling machines, automatic forming knife units.

Extruders, rolling machines, folding stations, guillotines, longitudinal knives, cross-cutting units

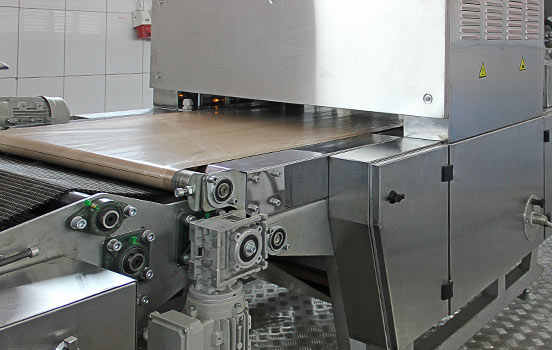

Majority of flat bread is baked in track tunnel ovens. There are continious ovens with electric or gas heating. Several temperature zones with individual adjustment of the upper and lower heating elements in each zone.

It bakes matzos on a metal mesh hearth in a baking chamber with several temperature zones with individual heat control for an optimal and fast baking process.

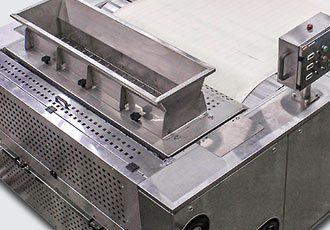

We offer two-tier electric or gas tunnel ovens for tortilla production. This oven type has loading conveyor, several temperature zones, speed adjusting of the oven conveyor and the baking time of the product.

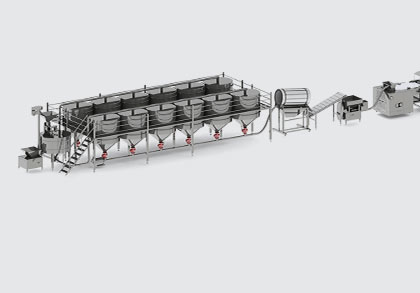

Рorizontal kneading machines, continious mixers, water and flour dispensers, sifters, dosing hoppers with dough feed system, cyclone hoppers and others…

There are proofing chambers of various capacities. Parameters of the preliminary proofing process (temperature and air humidity in the chamber) are controlled. Chambers have loading and unloading systems.

Multilevel, spiral, stabilisation, intermediate conveyors, forced cooling systems, humidifiers, stackers…

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?