OBTAINING A DOUGH RIBBON

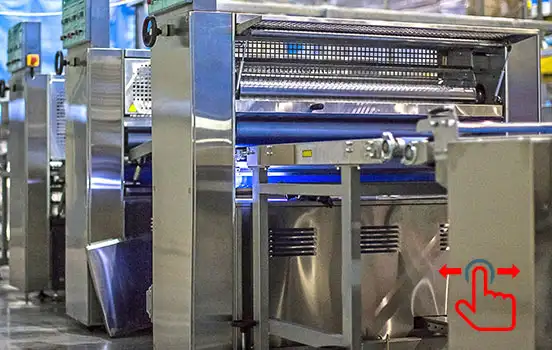

The dough ribbon of puff pastry is formed on a roller extruder and brought to the required thickness on a calibrator.

We offer a wide range of equipment and units for the production of puff pastry dough and danish pastries thereof: from "palmiers" and puff biscuits to croissants with various fillings and cakes based on puff pastry layers.

It totally automates the production process anabling to work with yeast and non-yeast puff pastry. The production is organized according to the latest consumer standards, modern design and ergonomics.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

The dough ribbon of puff pastry is formed on a roller extruder and brought to the required thickness on a calibrator.

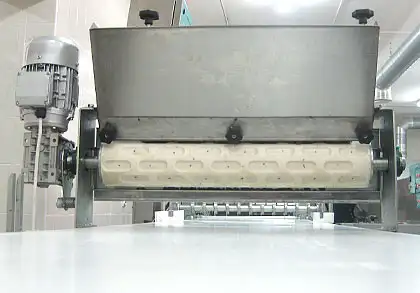

The fat extruder evenly places a layer of fat on the dough ribbon and afterwards the special units fold the dough over it.

The layered structure of the dough is obtained by use of cross-laying machines. The complete set of the line and machines design depend on the required number of layers.

After each lamination stage, the multiroller performs delicate rolling of the resulting puff pastry ribbon while maintaining the obtained dough structure.

The formation of puff pastry blanks is carried out by a set of units and machines for folding, twisting, two- and multi-layer stacking, notching the surface, etc.

Decoration of puff pastry products is performed by a set of machines and units for liquid and pasty fillings feeding, loose components sprinkling, liquid and pasty coatings application, etc.

The resulting puff pastry blanks are baked in various types of confectionery ovens. For high-capacity production, tunnel ovens are the optimal choice.

For the production of croissants, a special croissant forming machine is used. It cuts dough pieces from a dough ribbon and rolls them up.

The equipment can operate both in the form of independent units and as part of automatic integrated lines for the full cycle of danish pastries production from dough obtaining to packaging of finished products.

A special conveyor ensures an even supply of fat portions to the extruder. This allows to reduce the staff by replacing the continuous control of fat supply with periodic control by the operator of the line.

With a wide range of interchangeable forming and decorating units, our industrial puff pastry machine can produce a wide range of finished puff pastry products.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?

Delicious taste of puff pastry and wide opportunities for its use attract the attention of both confectioners and those who love sweets.

Confectionery products made of puff pastry are produced by many enterprises from small bakeries to large confectionery factories. Manual production requires high skills of confectioner. Therefore, with a growing production volume, equipment for puff pastry production with various degrees of automation is required.

Getting puff pastry is a time-consuming and complex process. As a rule, at small production volumes it is produced manually or by using ready frozen dough. Automatic forming is required only in such cases when the enterprise produces a large volume of puff pastry products or large batches of frozen puff pastry.

UTF-GROUP produces automatic lines for puff pastry production at the modern technical level. Due to its advanced design, it allows getting a product of a stable high quality with a minimum amount of fat (up to 15%).