ОБЛАДНАННЯ ДЛЯ ВИРОБНИЦТВА БАРАНКОВИХ ВИРОБІВ UTF GROUP-ЦЕ:

— комплексне рішення для організації виробництва баранкових виробів під ключ

— можливість повної автоматизації технологічного процесу на всіх етапах виробництва

— баранкова машина нового покоління, яка забезпечує високу якість готового продукту

— можливість інтеграції з існуючим обладнанням

— висока продуктивність при низьких витратах

ВИРОБНИЦТВО СУШОК - ВИГІДНІ ІНВЕСТИЦІЇ

Баранковіі вироби користуються традиційною популярністю на просторі колишнього СРСР і в Східній Європі. Цей класичний вид слов’янської народної випічки за рахунок простоти виготовлення, тривалого терміну зберігання та високої ціни продукції по відношенню до собівартості сировини є одним із вельми привабливих напрямків розвитку бізнесу.

Тому високопродуктивне виробництво сушок-човників, сушок-малюток, бубликів, бубликів та інших видів бубликів є дуже затребуваним на нашому ринку. Багато виробників прагнуть мати у своєму асортименті ці продукти як основний або додатковий продукт.

ВИПУСК БАРАНКОВИХ ВИРОБІВ ВИМАГАЄ ІНДИВІДУАЛЬНОГО ПІДХОДУ

Виробництво різних видів баранкових виробів має багато особливостей як на етапі приготування бараночного тіста, так і на етапах формування тестових заготовок та випічки.

Різні розміри, час вистоювання, час та температура випічки вимагають від обладнання високого рівня варіативності. У цьому необхідно забезпечити оптимальні умови отримання кожного типу продукту. Крім цього, на вимоги до обладнання значно впливає планована продуктивність.

Тому кожен проект потребує ретельного розгляду для забезпечення максимальної ефективності обладнання.

НАШІ РІШЕННЯ З ОБЛАДНАННЯ ДЛЯ ВИПУСКУ БАРАНОК

Вимоги до продуктивності та асортименту вирішуються застосуванням різної кількості формувальних машин, конфігурацією технологічного обладнання та параметрами печі. Кількість баранкових машин може бути збільшено з однієї до двох, трьох або п’яти штук. Заміна пневматичного приводу машини електромеханічним дозволила збільшити точність форми та розмірів заготовок та виключити застосування стисненого повітря.

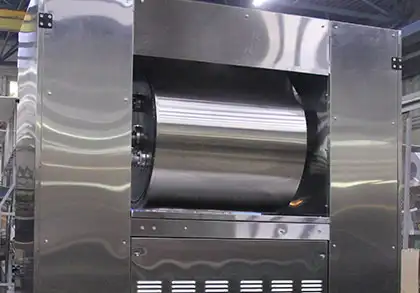

Треба відзначити, що виробництво різних видів баранкових виробів на одній печі вимагає широкого діапазону регулювання температури та швидкості руху (так час випічки може становити від 9 до 18 хв, а температура випічки від 165 до 290 Со).

Застосування електричних парогенераторів UTF GROUP різних моделей, що підбираються з урахуванням необхідної продуктивності лінії, та ошпарювальних камер з утилізацією відпрацьованої пари дозволяє отримувати баранкові вироби з привабливою блискучою поверхнею.

Լավաշի արտադրության սարքավորում

Լավաշի արտադրության սարքավորում