DOUGH PREPARATION EQUIPMENT:

Dough preparation is carried out on complexes for pre-ferment and finished dough preparation, which include a dough mixer with flour and water dispensers.

We manufacture automated production lines and other equipment for a wide range of bakery products.

Our lines automate all processes involved in the production of bakery goods, including the preparation of pre-ferment and dough, preliminary and final proofing, forming of dough pieces, baking, and cooling of finished products.

PRODUCTION CAPACITY

UP TO 700 KG/H

RANGE OF BUNS WEIGHT

25-140 G

Dough preparation is carried out on complexes for pre-ferment and finished dough preparation, which include a dough mixer with flour and water dispensers.

The supply of pre-ferment to the dough mixer in the finished dough preparation complex is mechanized. The bowl tipper lifts and unloads specially designed bowls.

.

The receiving hopper for finished dough can store two batches. A screw conveyor delivers the dough from the receiving hopper for further operations while preserving its structure.

The transfer of dough to the forming section is done by an inclined conveyor with covers for dust protection.

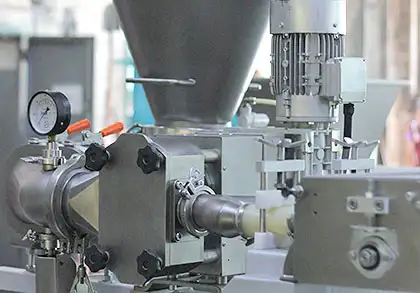

The dough is fed to the cutter by a screw unit and a pumping station, which ensures the stability of the portion weight. The pressure is monitored by a pressure gauge.

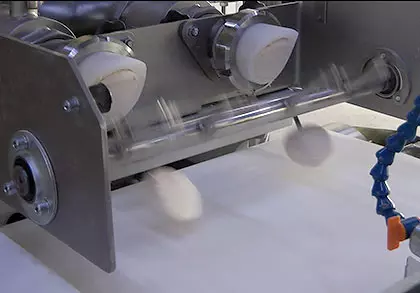

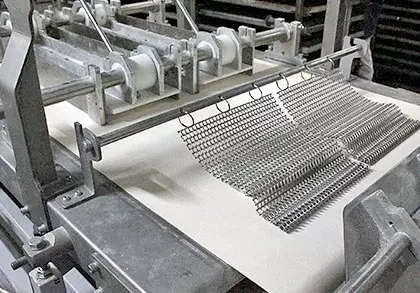

The portion divider delivers the set portions of dough in two rows. Portion separation is performed by a wire, the cutting step is controlled by a sensor.

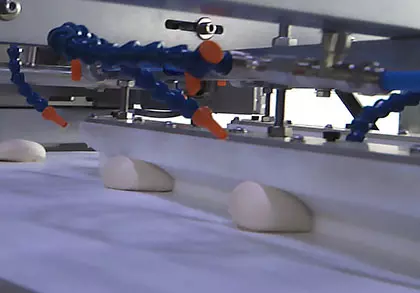

Dough pieces passing along the conveyor with guides get a spherical shape. The blowing unit prevents the dough from sticking to the belt.

The dough pieces are sprinkled with flour. Before sprinkling, the flour is sifted on a pneumatically driven tray. Excess flour is diverted for reuse.

The loading system accumulates and feeds the blanks into the cells of the pre-proofing chamber with a vibrating plate.

The blanks are moved inside the chamber by a chain conveyor in cradles and the proofing time is controlled by the speed of the conveyor.

In the chamber with controlled parameters of humidity and temperature the dough acquires the necessary structure.

After the proofing process is complete, the cradles are tipped over and the billets are fed to the moulding machines.

The rolling unit of the bun forming machine moulds the dough pieces received on the guides into the required shape.

To produce hot dog buns, the dough pieces are additionally passed through a rolling machine with a conveyor belt.

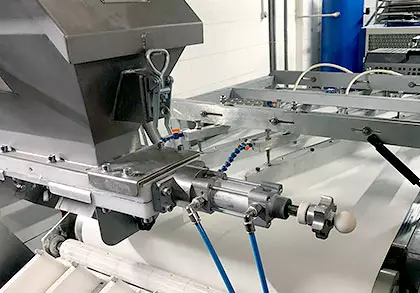

Dough pieces are placed on baking trays, which are fed by a stepper conveyor.

The laying process is automatic. Hot dog buns are stacked 2 in a row and hamburger buns 4 in a row.

The pan shaker shakes the pieces to center them in the baking tray sockets allowing the baked products to be perfectly shaped.

Excess flour is removed from the tray by the extraction system. The trays with the centered pieces are placed in a trolley for moving into the proofing chamber.

The final proofing of the dough pieces is carried out in a proofing chamber with four rows of trolleys. Proofing time and climate parameters are adjustable.

The trolleys with the trays move automatically inside the proofing chamber. When the proofing process is complete, a light signal illuminates above the corresponding exit.

The trays with the dough pieces are fed onto a conveyor belt, which guides them into the oven for finished products baking.

The trays are moved along the conveyor belt in steps equal to the length of the tray, the feeding is controlled by pneumatically driven lifting tables.

The machine of spraying and sprinkling of workpieces ensures the sprinkling of products with sesame, poppy seeds and other loose components.

A roller conveyor with step-by-step feeding accumulates trays to fill the entire width of the baking chamber and then feeds them into the oven.

The products are baked directly on the trays. Up to three rows of trays can be baked simultaneously.

The convection system ensures temperature equalization and optimal heat distribution in the baking zones.

Additional heating channels are available to partially replace electric heating elements with other heat sources.

Inside the oven there is a steam treatment area with steam supply from a steam generator.

At the outlet of the oven there are conveyors that take the trays from the oven and move them with acceleration to the conveyor which removes them from the oven at an angle of 90°.

The baked buns are removed from the tray and cooled automatically.

At the oven exit, a conveyor takes the trays and moves them to the depaner.

The depaner with vacuum suction cups removes the finished products from the trays and places them on the cooling conveyor.

The cooling systems for the finished products and trays are designed separately for each project, taking into account the layout of the room and the customer’s requirements.

Spiral conveyors are used for cooling of the finished products in order to save space.

The machine for cutting burger buns allows you to cut buns for further packaging.

To produce a hot dog bun, the bun cutting and drilling machine cuts off one end of the bun and makes a hole in it.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?