HARD BISCUITS (COOKIES)

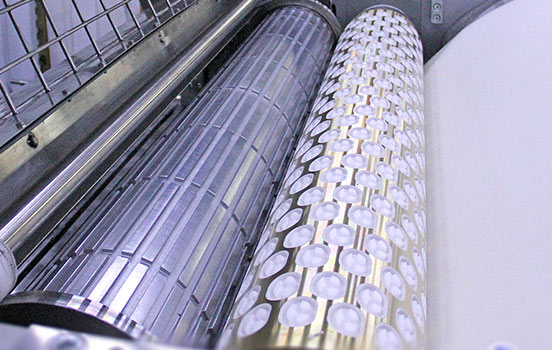

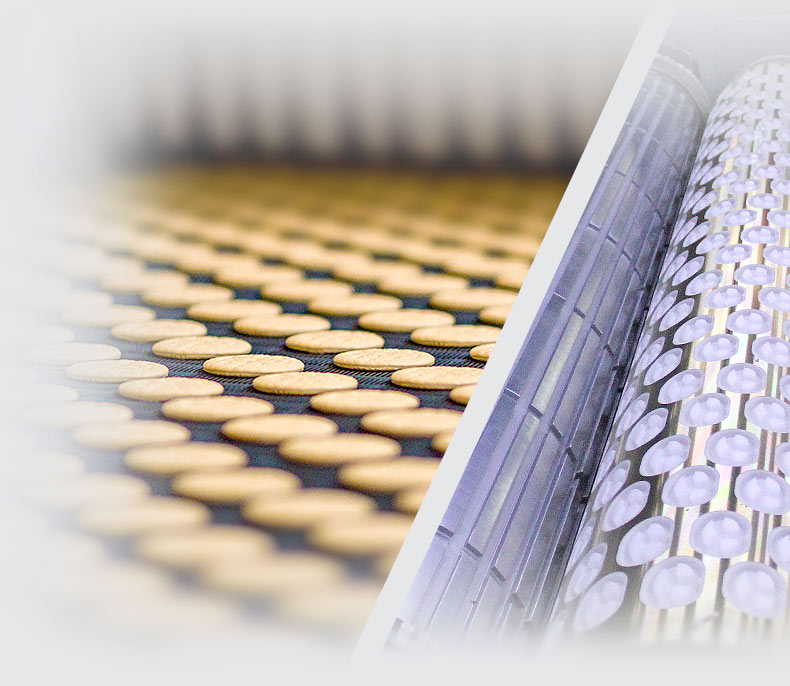

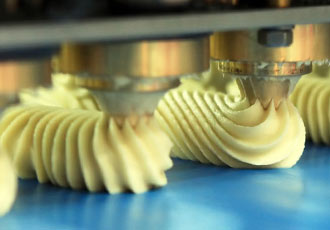

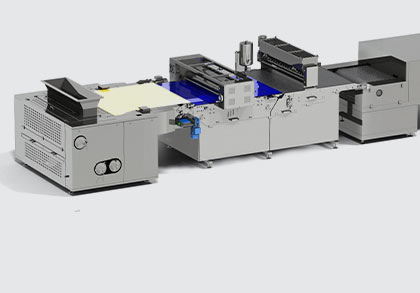

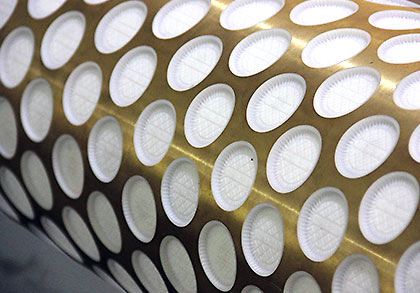

Digestive or semi-sweet biscuits are made from dough with low fat and sugar content. The dough for this cookie is elastic and stretchy, requires long multi-stage rolling with resting between stages. Biscuit blanks are formed by industrial cutting machines.

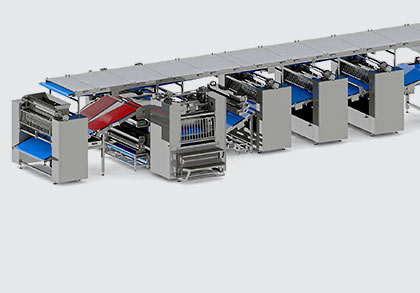

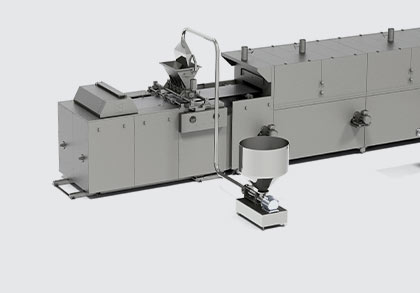

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H