LAVASH PRODUCTION LINE HAS BEEN SUPPLIED TO ODESSA

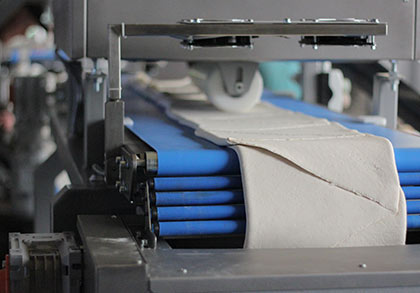

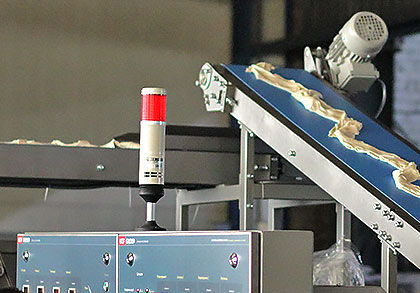

An automatic line for lavash production with a capacity of 100 kg/h has been shipped to Odessa.

The line is designed to produce thin lavash in various sizes and shapes for grocery stores and fast food outlets.

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

More

More

More

More

More

More