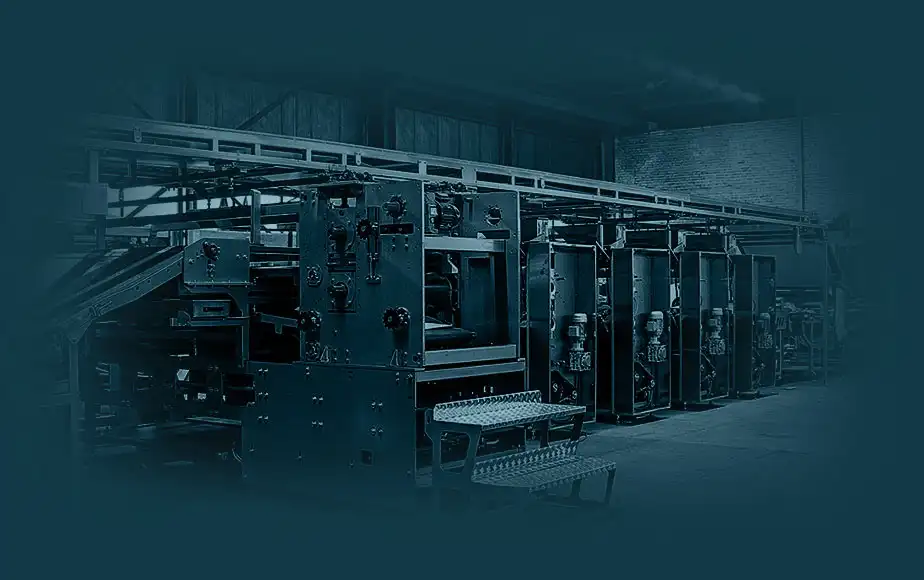

PAPAD FORMING MACHINES

Papad blanks are formed from a dough tape that fits into the layers of a horizontal spreadsheet and is rolled out to a certain thickness.

Automatic equipment is developed for papad production, appadam, happala, papad and other types of national bread which similar to them.

Hhigh performance, reduction of manual labor, advanced control system, operates 24 hours a day, compliance with European hygiene requirements.

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

Papad blanks are formed from a dough tape that fits into the layers of a horizontal spreadsheet and is rolled out to a certain thickness.

Drying is carried out in conveyor drying chambers, in which hot air dries dough pieces, ensuring high equipment productivity and product quality.

After drying, the conveyor system supplies the drying papad to the packaging machine. The design of the conveyors ensures maximum service life.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?

India is a country of great cultural and national diversity, which generates an even greater diversity of national kitchen. One of the important elements on each table is the traditional national bread. And Indian is not an exception – there are dozens of kinds of bread in the country, which differ in the names, recipes, and preparing method.

One of the bread types is papad – flatbread baked from flour obtained from Urdu, lentil, chickpea, rice, tapioca, and some other plants. There are many names and varieties – appalam, pappadam, appadam, happala, pappadum and others.

The final baked papad happens immediately before a meal when dry papad is fried in oil. the most difficult moments in the production process are flatbread. Traditionally, this was done by drying them in sun, but for machine production such a method is unacceptable and drying is carried out in drying chambers which hot air dries the dough pieces, ensuring high performance and quality of the resulting papad.