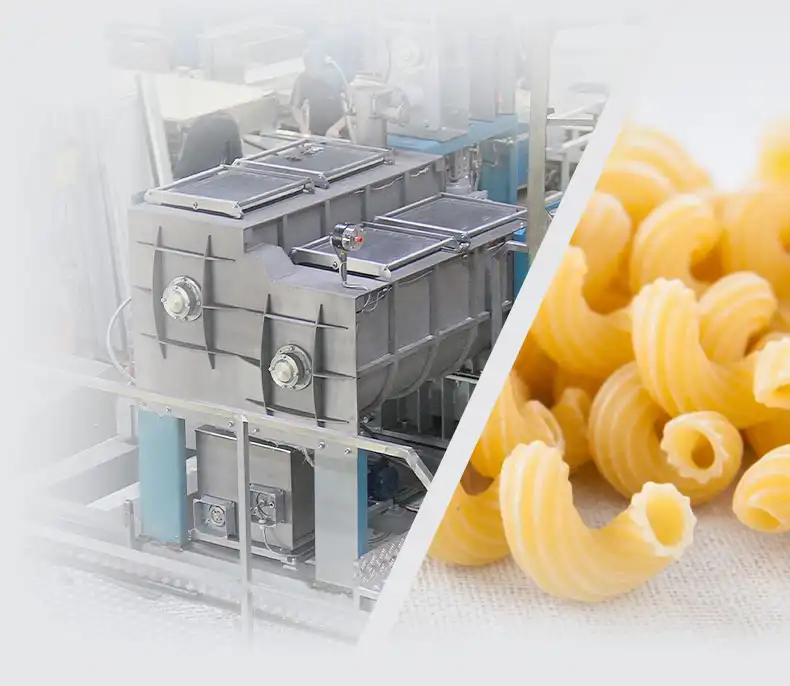

UTF-GROUP GUARANTEES PRODUCTION OF HIGH-QUALITY PASTA

Getting high-quality pasta is a difficult process. There are many details that determine quality at all stages of production – from dough preparation to stabilization of ready-made pasta.

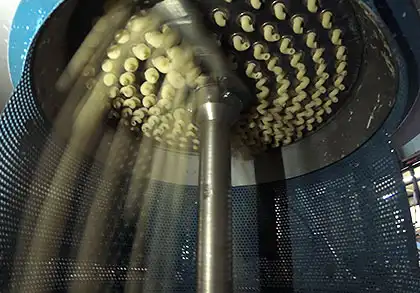

High-speed mixing at the inlet ensures perfect hydration of the raw materials, fully moistening each particle of flour.

Mixing of the pasta dough in a vacuum condition throughout the whole process ensures high-quality of dough. At the same time, besides air removal and compaction of the dough, the glassiness of the products improves and the roughness decreases, the darkening of dough does not occur.

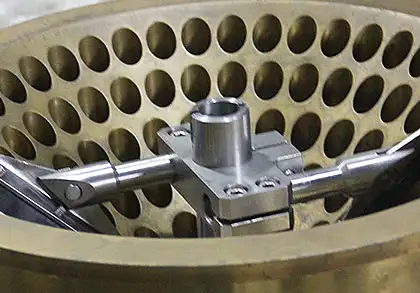

Installation of filtering mesh and grate, individual for each extrusion die, ensures the correct shape and length of pasta.

The use of the Italian low-temperature drying technology with the delicate removal of excess moisture from pasta allows avoiding the appearance of cracks in the production of thick-walled pasta.

PASTA EQUIPMENT FROM UTF-GROUP PROVIDES

— long service life

— work in any climatic conditions

— low maintenance

— high energy saving

— compliance with European safety and hygiene requirements

— installation and commissioning works anywhere in the world

— constant service support with round-the-clock communication channel

— staff training for safe and efficient operation of the line

— free advice on the operation and expansion of possibilities of the equipment

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H