PITA

Pita (pitta) is a round, flat, unleavened bread made both from wholemeal flour as from the premium wheat flour. It is extremely popular on the Mediterranean coast and in the Middle East countries.

We produce equipment for the production of various types of pita.

Automatic and semi-automatic lines with a capacity from 1,200 and to 7,200 units per hour make possible to organize both a small bakery workshop and a large pita production enterprise.

UTF GROUP, one of the largest manufacturers of industrial lines and equipment for the production of national types of bread in Europe

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

Pita (pitta) is a round, flat, unleavened bread made both from wholemeal flour as from the premium wheat flour. It is extremely popular on the Mediterranean coast and in the Middle East countries.

There are many pita varieties: Arabic, Greek, Israeli, Iraqi (laffa), etc.

A distinctive feature of the traditional pita is that the water steam released from the dough during baking accumulates in a bubble in the center of the cake, separating dough layers.

Thus, a “pocket” is formed inside the flatbread, it can be opened by cutting the edge of the pita with a sharp knife. You can stuff it by salads, meat and other fillings.

The automatic dough divider dispenses portions of dough of a given size, which are fed for preliminary proofing. Then, rolling machines form dough blanks by sequential rolling in two perpendicular directions.

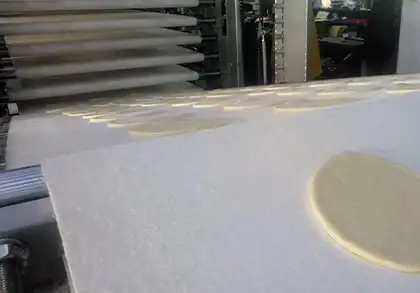

Another technology for pita production consits in cutting out dough blanks from dough ribbon. Extruder forms a dough ribbon, cutting is performed by drums with plastic knives with a wide rounded edge, due to which pita dough pieces with pressed edges are obtained.

Proofing is a mandatory step in the production of pita. Two-stage proofing of the dough in conveyor chambers ensures the production of high quality finished products in automatic mode.

Some varieties of pita do not require two stages of dough proofing. In this case, only one chamber is used for dough pieces proofing.

Pita is baked in a track tunnel oven with electric or gas heating. The oven is customized for baking of national types of bread

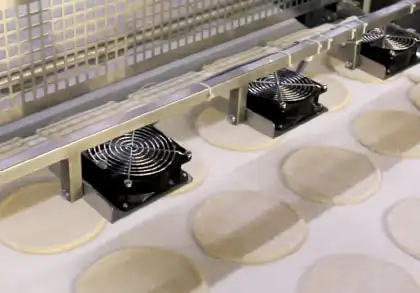

Complex technical solutions are used to save space: multilevel, spiral conveyors, forced cooling systems, etc.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?

An important element in the automation of pita production is the automation of the proofing process. The proofing should be carried out in two stages: the first stage -before rolling, the second – before baking. Conveyor proofing chambers ensure proofing without disrupting the whole technological process. For maximum space saving, the proofing chambers has the multitier design and the complex trajectory of movement