ОБОРУДОВАНИЕ ДЛЯ ПОДГОТОВКИ ТЕСТА

специально разработано для производства национальных видов хлеба и включает оборудование для дозирования компонентов теста и тестомесильное оборудование

Изготовление ряда линий с различной производительностью - от 500 до 2400 шт/ч.

Традиционная технология производства питы. Двойная автоматическая расстойка теста.

Работа в непрерывном круглосуточном режиме. Индивидуальные решения под каждый проект.

UTF GROUP - украинский завод-изготовитель, разработчик и проектировщик оборудования для пищевой промышленности с опытом более 25 лет

МОДЕРНИЗИРУЙТЕ СВОЕ ПРОИЗВОДСТВО С ОБОРУДОВАНИЕМ UTF GROUP

Производительность

1200, 2400 шт/час

диаметр продукта

до 300 мм

специально разработано для производства национальных видов хлеба и включает оборудование для дозирования компонентов теста и тестомесильное оборудование

отделяет порции теста заданной массы с высокой точностью для получения готовой питы одинакового размера

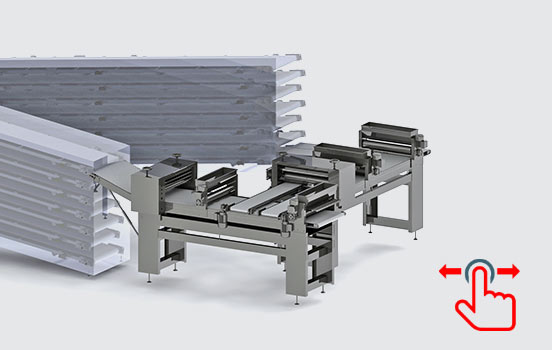

порций теста выполняется на многоярусной конвейерной расстоечной камере

порций теста для получения тестовых заготовок питы выполняется на двух раскаточных машинах, при этом раскатка теста проводится в двух направлениях

полученных тестовых заготовок выполняется на многоярусной конвейерной расстоечной камере

разработанная специально для выпечки национальных видов хлеба обеспечивает оптимальные условия для выпечки питы

готовой питы до температуры упаковки производится на конвейерах системы охлаждения с естественным или принудительным охлаждением

Охлаждение питы при большом объеме производства требует большой длины конвейеров системы охлаждения. Для уменьшения занимаемой ими площади возможно применение многоярусных спиральных конвейеров.

ХОТИТЕ ПОЛУЧИТЬ КОММЕРЧЕСКОЕ

ПРЕДЛОЖЕНИЕ?

УЗНАТЬ СТОИМОСТЬ ЛИНИИ

И ДОПОЛНИТЕЛЬНОГО ОБОРУДОВАНИЯ?