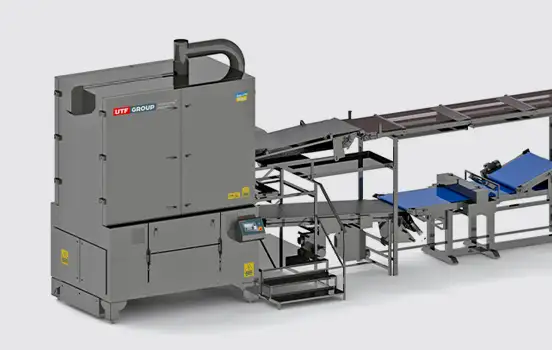

Система управления линией может быть как аналоговой, так и цифровой с сенсорными экранами «Touchscreen».

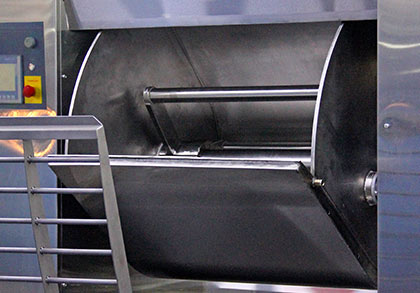

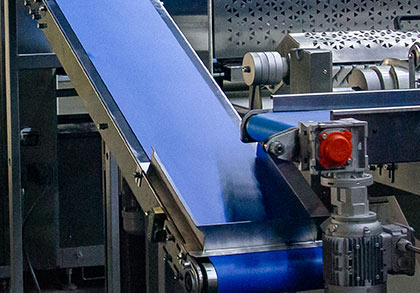

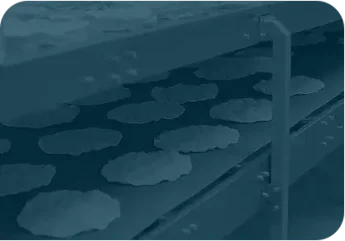

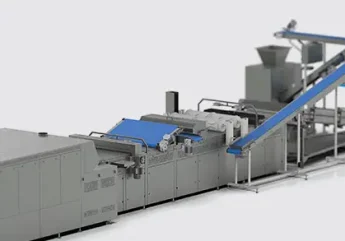

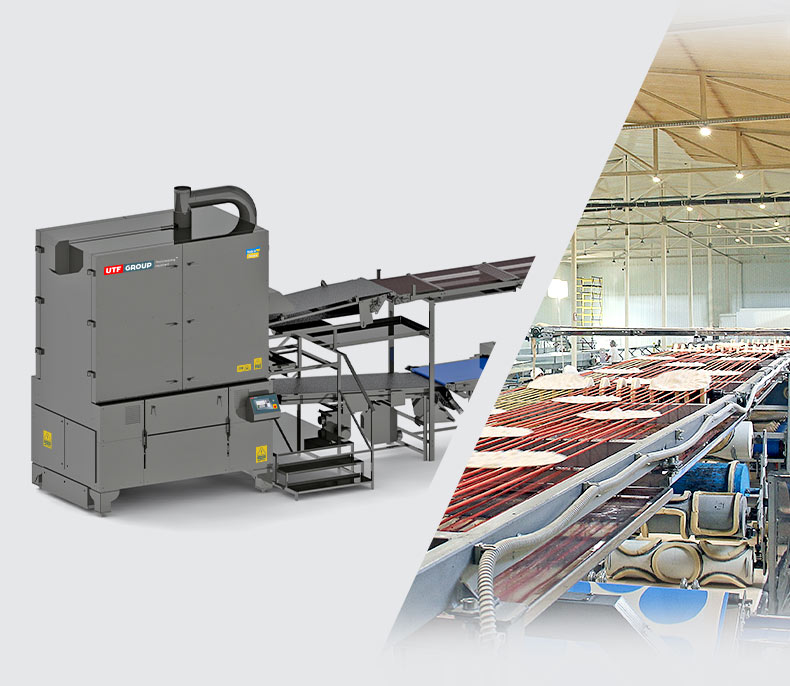

ОБОРУДОВАНИЕ ДЛЯ ПРОИЗВОДСТВА ГАРНИЙСКОГО ЛАВАША

Производство автоматизированных промышленных линий и оборудования для гарнийского лаваша.

Полная автоматизация производственного процесса. Минимальная занимаемая площадь за счет многоярусной компоновки. Минимальные потери тепла благодаря тупиковой конструкции печи.

Производительность линий до 150 кг/ч

Автоматические линии для производства лаваша

Автоматические линии для производства лаваша