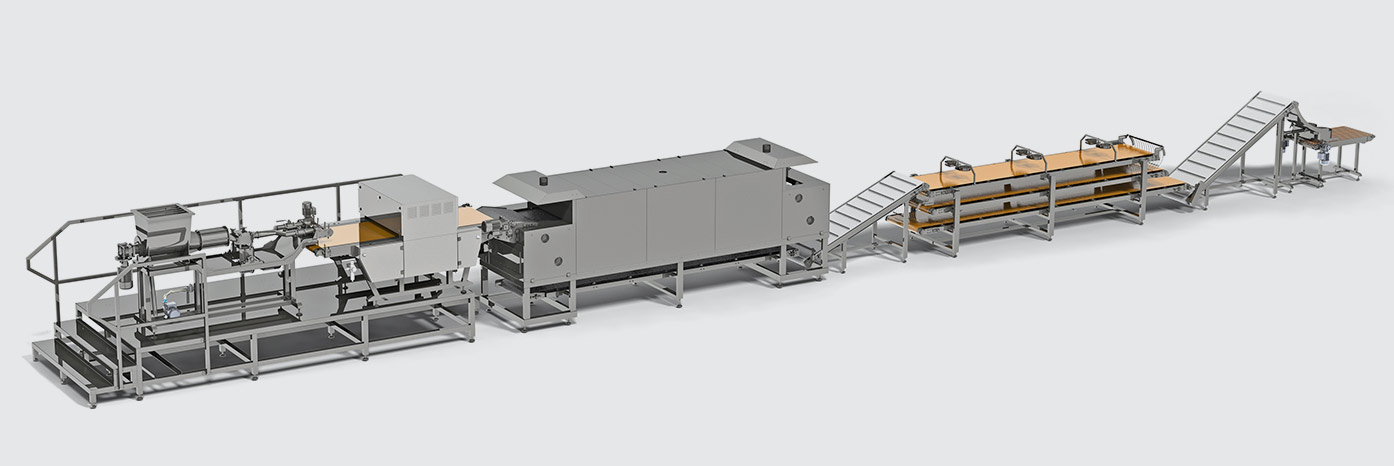

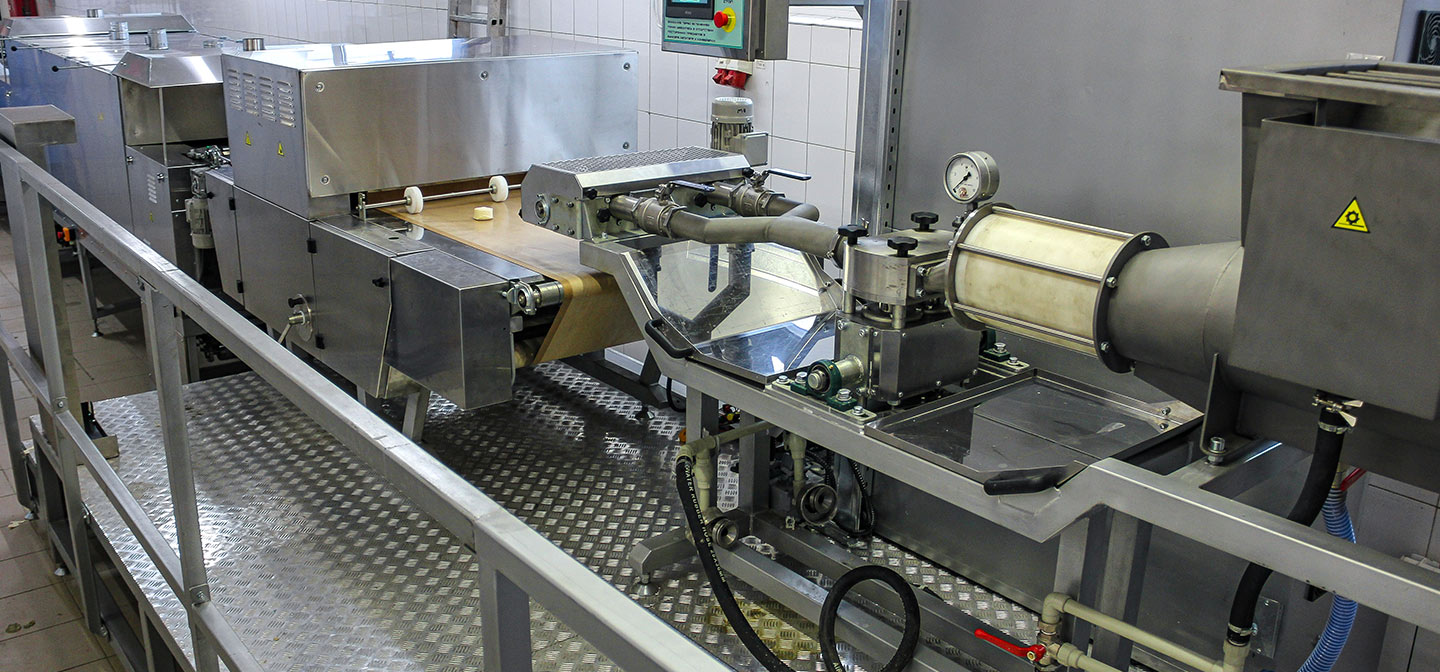

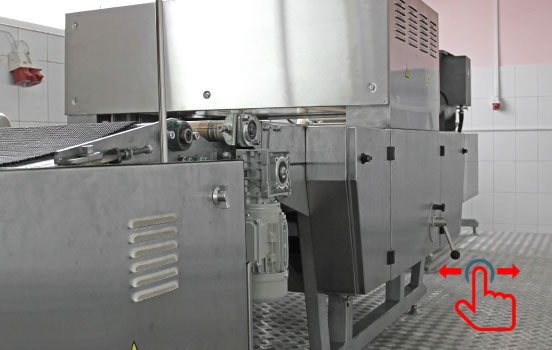

Спроектировано на базе лучших технических решений для обеспечения многолетней надежной работы. Занимает небольшую площадь благодаря компактной конструкции

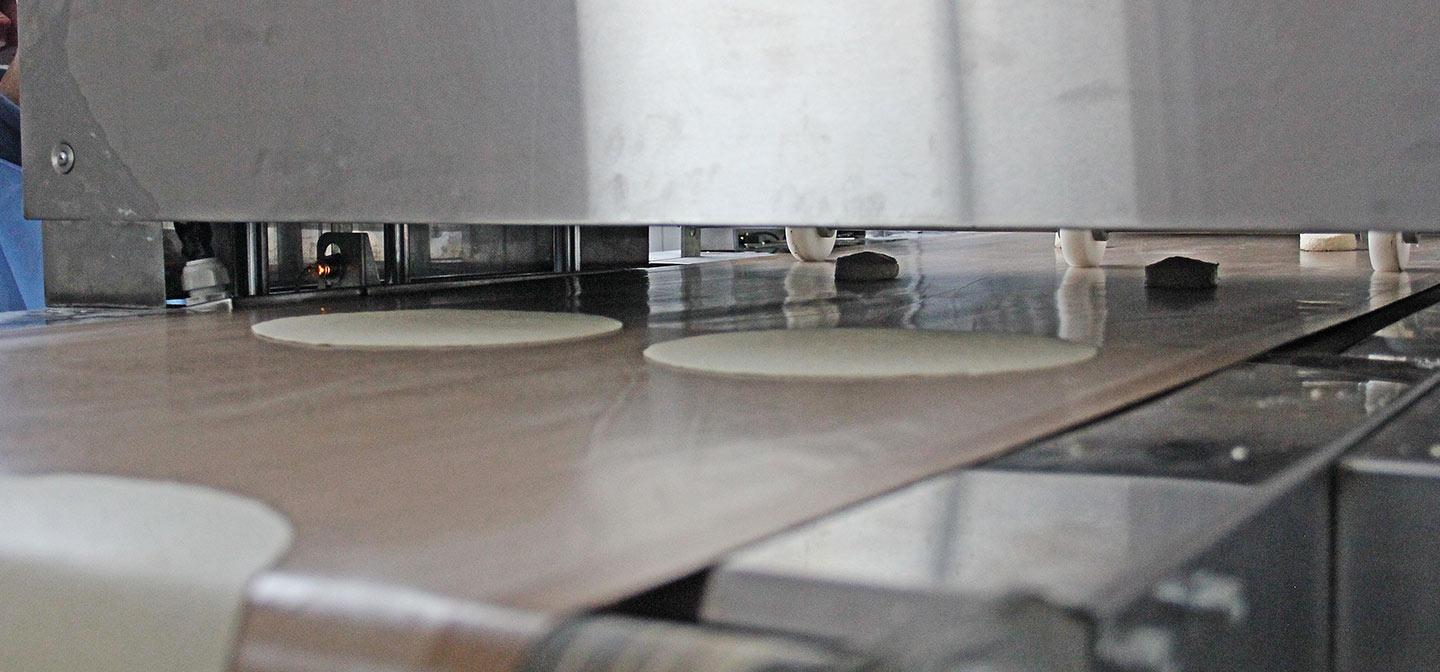

АВТОМАТИЧЕСКАЯ ЛИНИЯ

ДЛЯ ПРОИЗВОДСТВА

ПШЕНИЧНОЙ ТОРТИЛЬИ

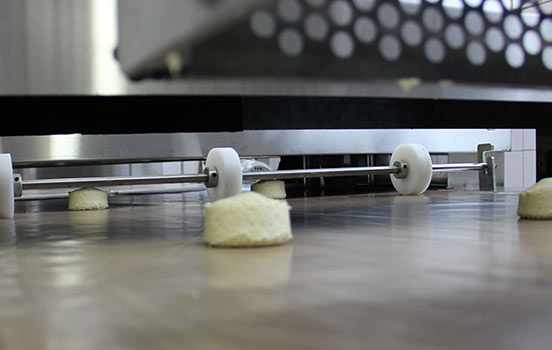

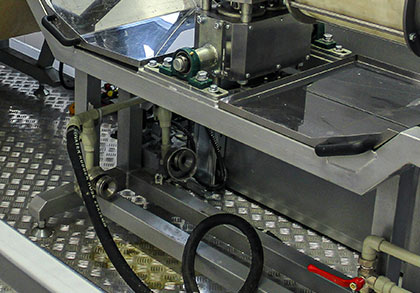

Высокая производительность оборудования. Пневматический привод пресса. Отсутствие обрезков теста. Полная автоматизация технологического процесса.

Автоматические линии для производства лаваша

Автоматические линии для производства лаваша