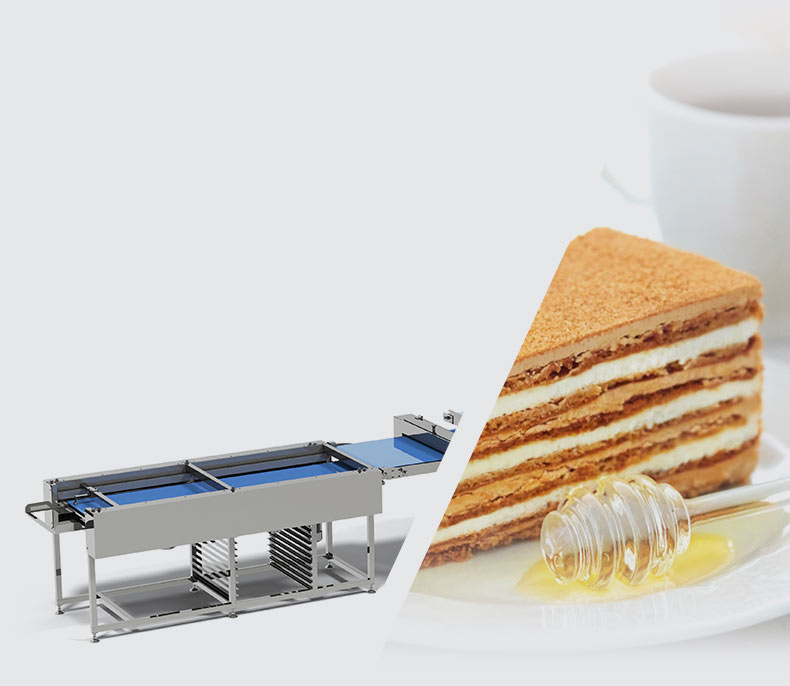

ПОДВІЙНИЙ КАЛІБРАТОР

Для отримання тонких заготовок застосовується двоетапне калібрування стрічки тіста, що дозволяє отримати необхідну товщину із збереженням структури тіста.

Для тортів типу "МЕДОВИК" та "НАПОЛЕОН"

Виробництво коржів тортів різної форми та розмірів. Виготовлення коржів тортів із листкового та пісочного тіста. Швидкий перехід з одного типорозміру на інший. Висока продуктивність

UTF GROUP - український виробник і проектувальник обладнання для харчової промисловості з досвідом понад 25 років

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

ПРОДУКТИВНІСТЬ

до 150 кг/год

ВСТАНОВЛЕНА ПОТУЖНІСТЬ

3,5 кВт

ОБСЛУГОВУЮЧИЙ ПЕРСОНАЛ

2 людини

Для отримання тонких заготовок застосовується двоетапне калібрування стрічки тіста, що дозволяє отримати необхідну товщину із збереженням структури тіста.

Система управління може бути аналогової чи цифрової на основі промислового контролера.

Застосування автоматичного укладання заготовок на деко дозволяє виключити ручну працю при цієї операції.

Можливе встановлення системи конвеєрів, яка забезпечить повернення обрізків тіста від формувального столу до екструдера в автоматичному режимі.

виробництва провідних світових виробників (Ammeraal\Habasit\Chiorino)

частотними перетворювачами Schneider Electric

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?