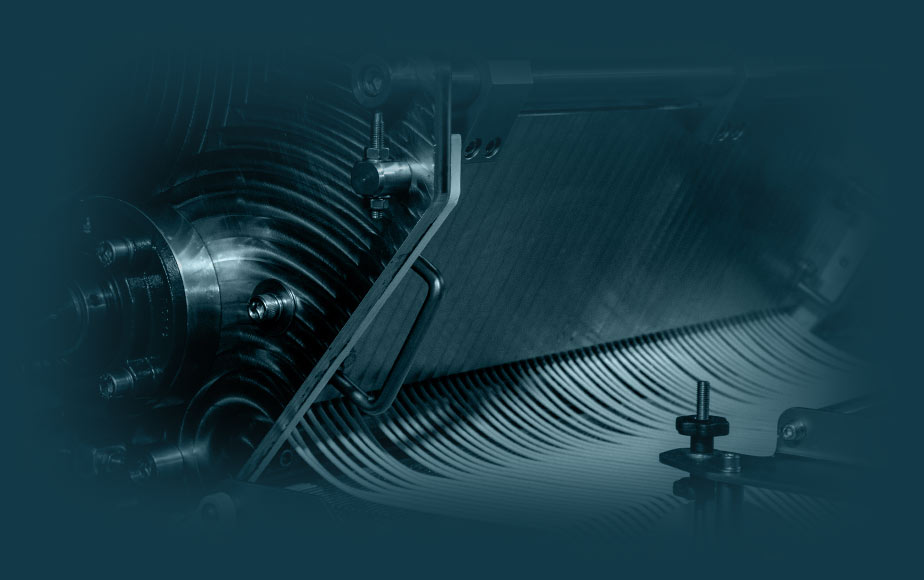

ФОРМУЮЩАЯ МАШИНА СОЛОМКИ

формирует тестовые жгуты заданного диаметра, которые для исключения склеивания равномерно распределяются по ширине конвейера

Производительность от 80 до 150 кг/ч

Выпуск соломки различных видов: сладкой, соленой, ванильной, киевской.

Полная автоматизация процесса производства. Продукт различной длины и диаметра

UTF GROUP - украинский завод-изготовитель, разработчик и проектировщик оборудования для пищевой промышленности с опытом более 25 лет

МОДЕРНИЗИРУЙТЕ СВОЕ ПРОИЗВОДСТВО С ОБОРУДОВАНИЕМ UTF GROUP

ПРОИЗВОДИТЕЛЬНОСТЬ

100-250 КГ/ЧАС

ДЛИНА ПЕКАРНОЙ КАМЕРЫ

ДО 30 М

ШИРИНА ПОДА ПЕЧИ

1000-2000 ММ

ОБСЛУЖИВАЮЩИЙ ПЕРСОНАЛ

2 ЧЕЛОВЕКА

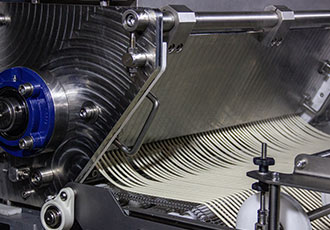

формирует тестовые жгуты заданного диаметра, которые для исключения склеивания равномерно распределяются по ширине конвейера

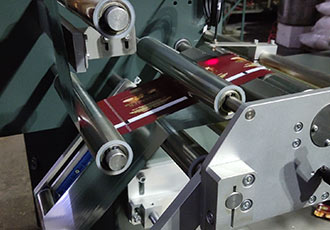

придает соломке золотистый оттенок, для чего тестовые жгуты пропускают через ванну с нагретым до 70-90°С раствором двууглекислого натрия

надсекает тестовый жгут для формирования будущей линии надлома готового продукта, расстояние между надсечками является длиной соломки и регулируется системой управления

для расширение ассортимента возможна посыпка тестовых жгутов сыпучими компонентами (солью, маком, кунжутом и т.п.)

выпекает соломку на сетчатом металлическом поде в пекарной камере с несколькими температурными зонами

охлаждает соломку после выпечки до температуры упаковки на системе ленточных транспортеров

Формующая часть линии производства соломки является отдельным комплексом оборудования, что дает возможность его совместной работы с существующими на предприятии заказчика туннельными печами с сетчатым подом.

Для автоматизации процесса упаковки возможно обеспечить интеграцию в состав линии машин для упаковки соломки в полиэтиленовые пакеты, картонные ящики и другие виды упаковки.

ХОТИТЕ ПОЛУЧИТЬ КОММЕРЧЕСКОЕ

ПРЕДЛОЖЕНИЕ?

УЗНАТЬ СТОИМОСТЬ ЛИНИИ

И ДОПОЛНИТЕЛЬНОГО ОБОРУДОВАНИЯ?