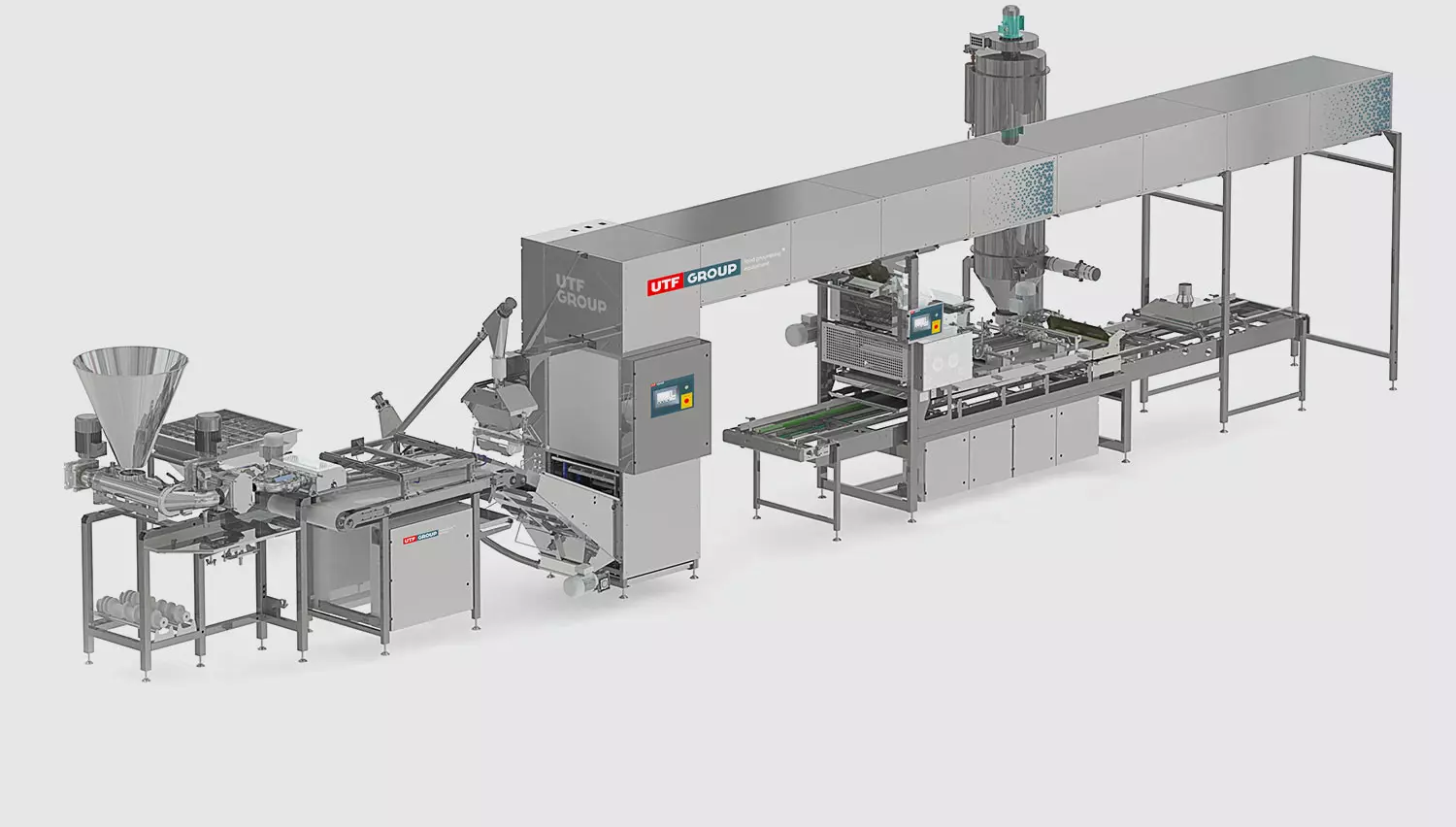

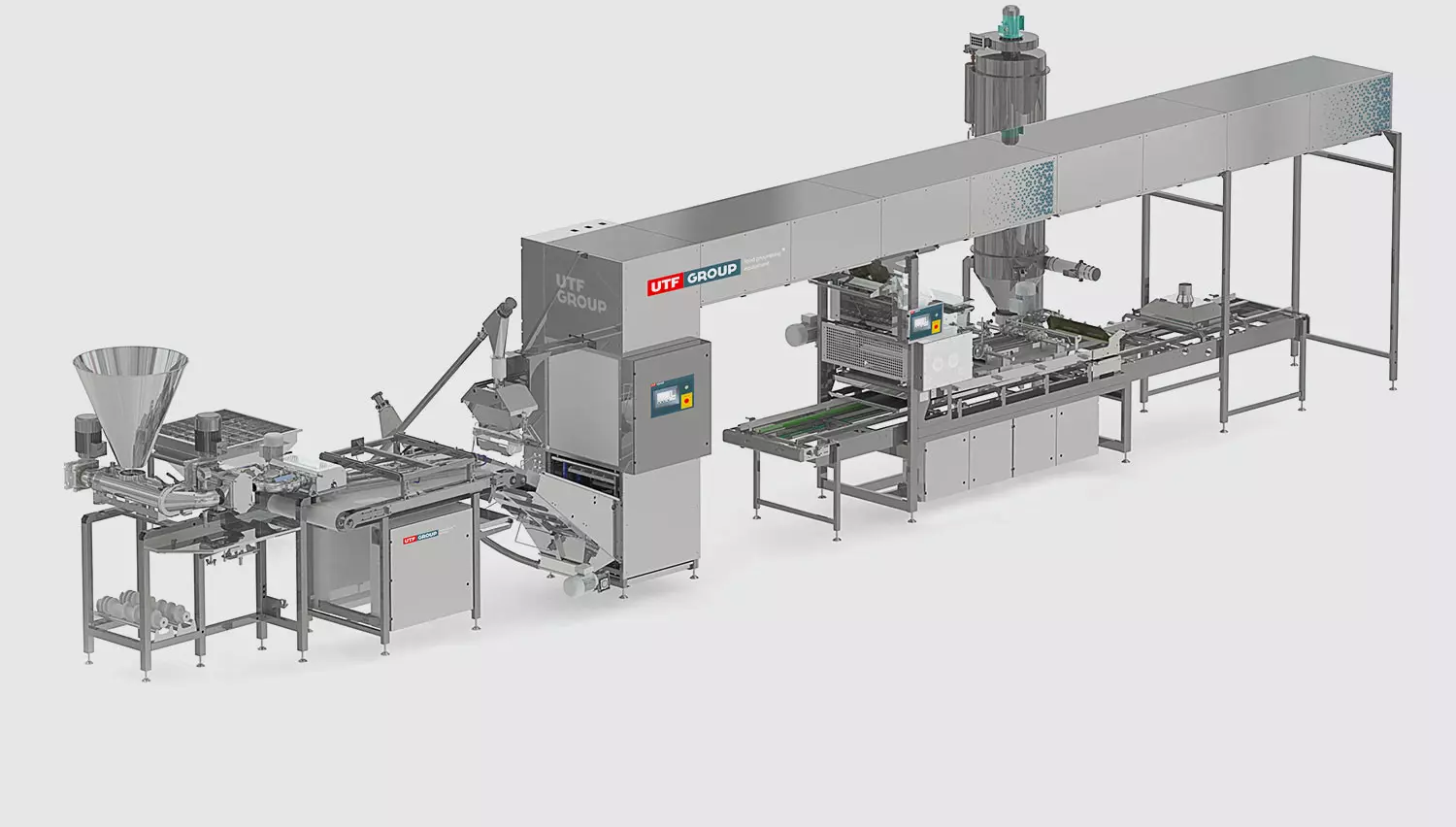

DOUGH PIECE DIVIDER

The dough piece dividing machine delivers set portions of dough in two rows. The portion separation is performed by a wireg, the cutting step is controlled by a sensor.

The process of dough pieces forming for various bakery products including burger buns and hot dog buns is fully automated.

The forming area can work with both tunnel and rotary ovens.

Capacity

up to 500 kg/h

burger buns

up to 5000 pcs/h

hot dog buns

up to 4000 pcs/h

Piece weight

25-140 g

The dough piece dividing machine delivers set portions of dough in two rows. The portion separation is performed by a wireg, the cutting step is controlled by a sensor.

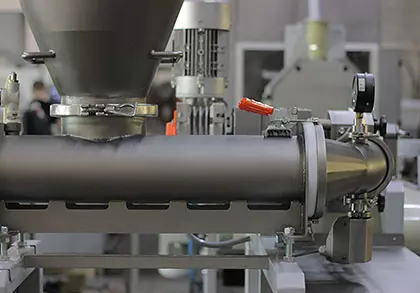

The dough is fed for cutting by a screw unit and a pumping station, which ensures the stability of the portion weight. The pressure is controlled by a pressure gauge.

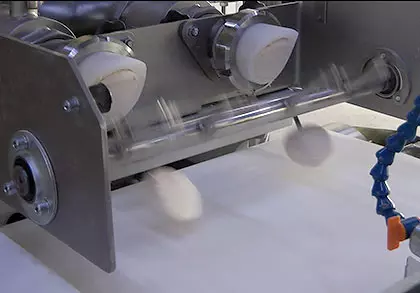

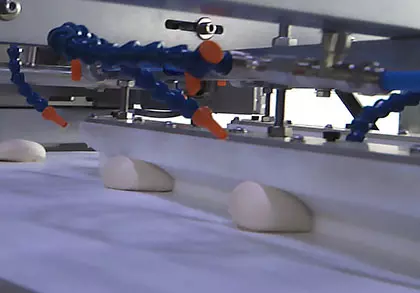

Workpieces passing through the conveyor with guides get a spherical shape. The blowing unit prevents the dough from sticking to the belt.

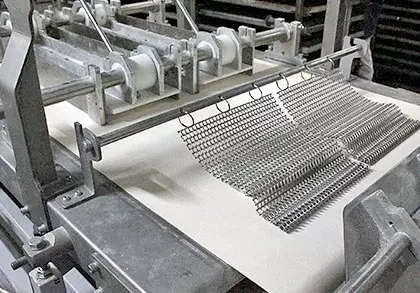

The dough pieces are sprinkled with flour. Before sprinkling, the flour is sifted on a pneumatically driven tray.

Excess flour is diverted by a screw conveyor into a separate container for reuse.

It accumulates 4 workpieces, then they are fed into the cells of the proofing chamber. Feeding is carried out with a vibrating plate

In the chamber, under controlled parameters of humidity and temperature, the dough pieces take the desired shape and the dough acquires a uniform microporous structure.

The dough pieces are moved inside the chamber by a chain conveyor in cradles and the proofing time is adjustable. After the process is completed, the cradles are tipped over and the blanks are fed to the forming machines.

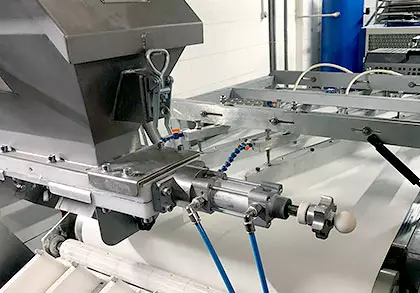

The rolling unit of the bun forming machine gives the dough pieces the required shape by means of feeding along the guides.

To produce hot dog buns, the dough pieces are additionally passed through a rolling machine with a feeding conveyor.

The trays are fed manually, moving along the conveyor in steps. Hot dog buns are loaded 2 in a row, hamburger buns 4 in a row.

Flour from the trays is removed by the extraction system and accumulated in the hopper with filters.

The panshaker shakes the pieces to center them in the baking tray sockets allowing to obtain perfectly shaped products during baking.

Buns can be baked in both tunnel and rotary ovens. With rotary ovens, the trolleys are fed directly into the ovens.

When working with tunnel ovens, the trays are placed on a special conveyor belt, which feeds them to the conveyor belt of the tunnel oven.

We also offer a complete range of industrial equipment for the production of buns and bakery products starting from dough preparation to product cooling

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?