Conclusion — where the industry is headed and what we offer

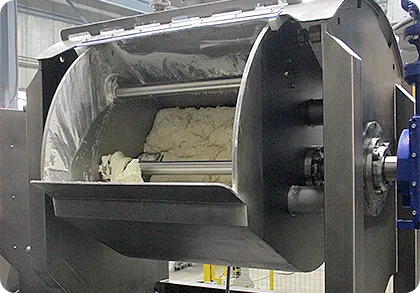

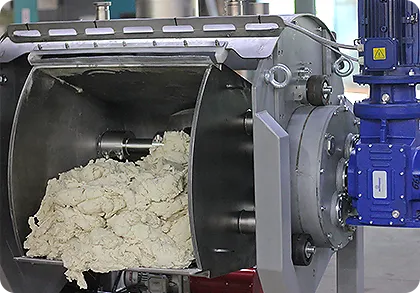

Today, dough preparation is one of the key stages in bakery and confectionery production. Modern requirements for hygiene, energy efficiency, speed, and flexibility of processes set increasingly high standards for equipment manufacturers, stimulating the search for new engineering solutions and approaches to the design of professional dough mixers.

Key market trends

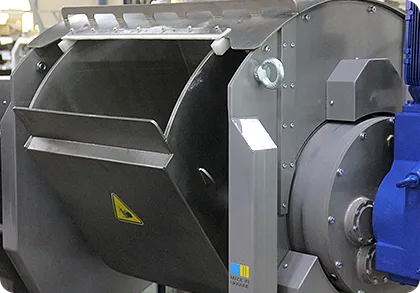

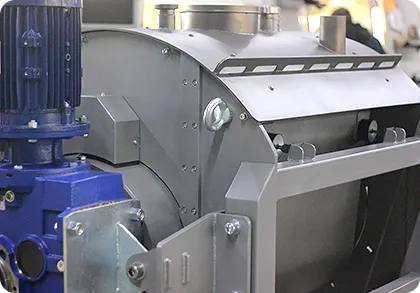

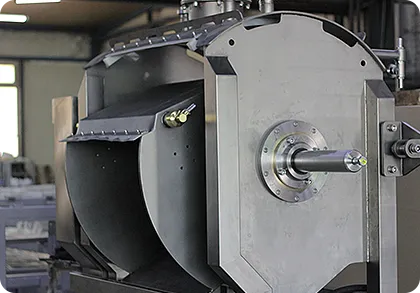

Open frame designs — for hygiene and ease of maintenance;

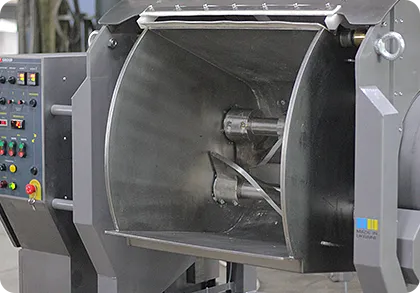

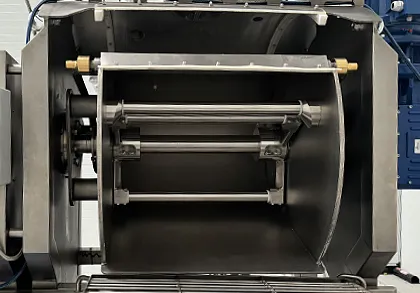

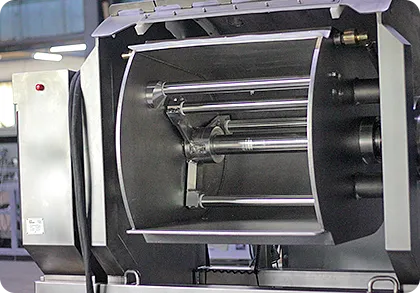

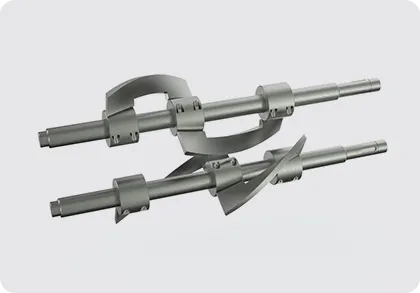

A variety of mixing elements — for specific types of dough and recipes;

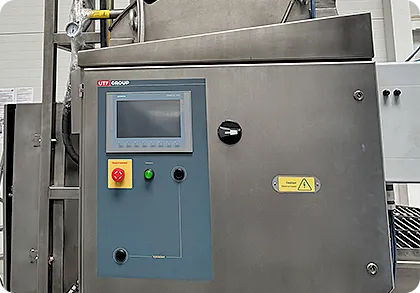

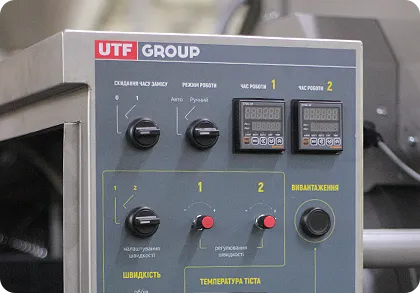

Speed control and mixing curve formation — for precise texture control;

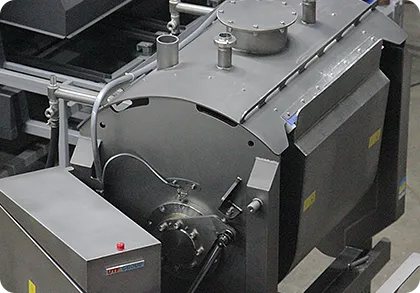

Bowl cooling or heating (jackets, double walls) — for temperature stability;

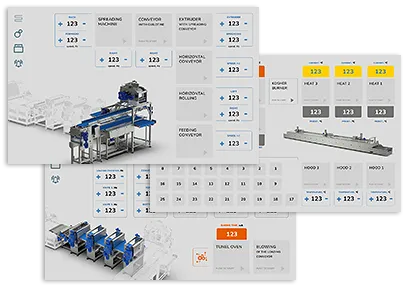

Integration with liquid and bulk ingredient dosing systems;

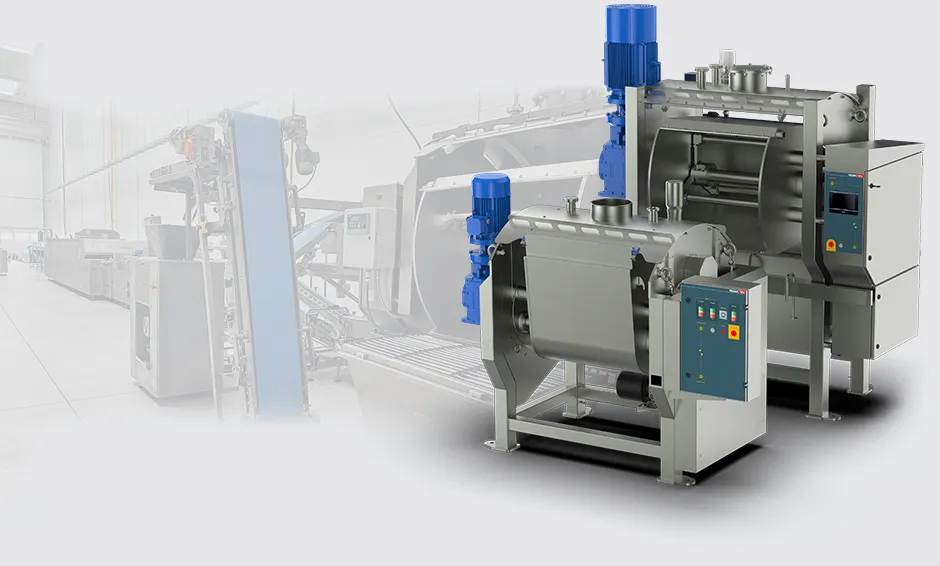

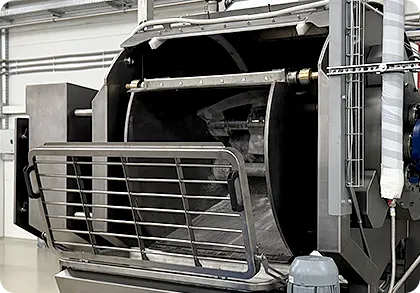

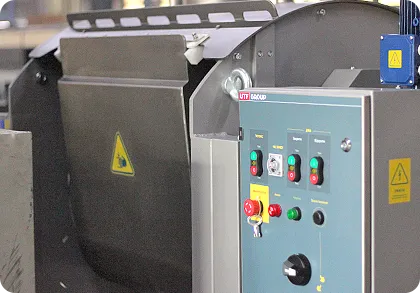

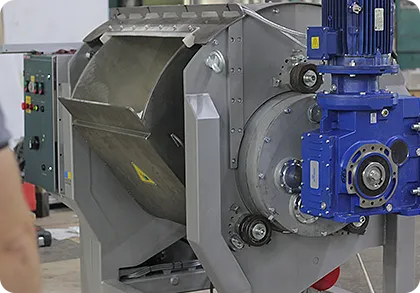

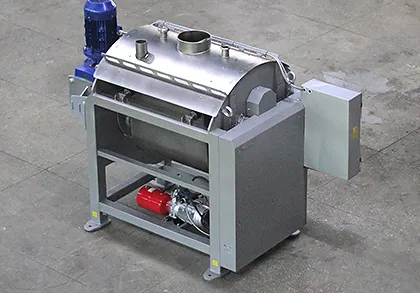

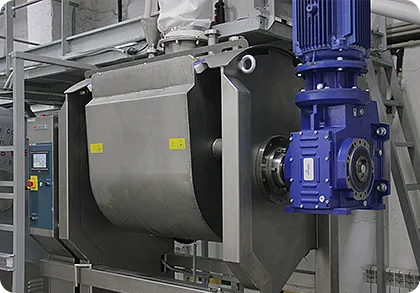

UTF GROUP horizontal dough mixers are a modern and competitive solution, created with the characteristics of Ukrainian production and the practical requirements of technologists in mind.

We don’t just create equipment — we build an ecosystem of horizontal dough mixers and auxiliary modules that work as a single, integrated system, where you can:

select a model or complex for a specific product;

adapt the design to the technological line and recipe;

be confident in the reliability of the equipment, protection of investments, and sustainable growth of production.

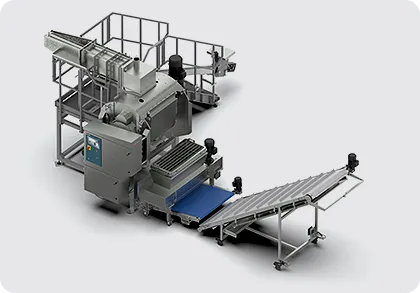

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H