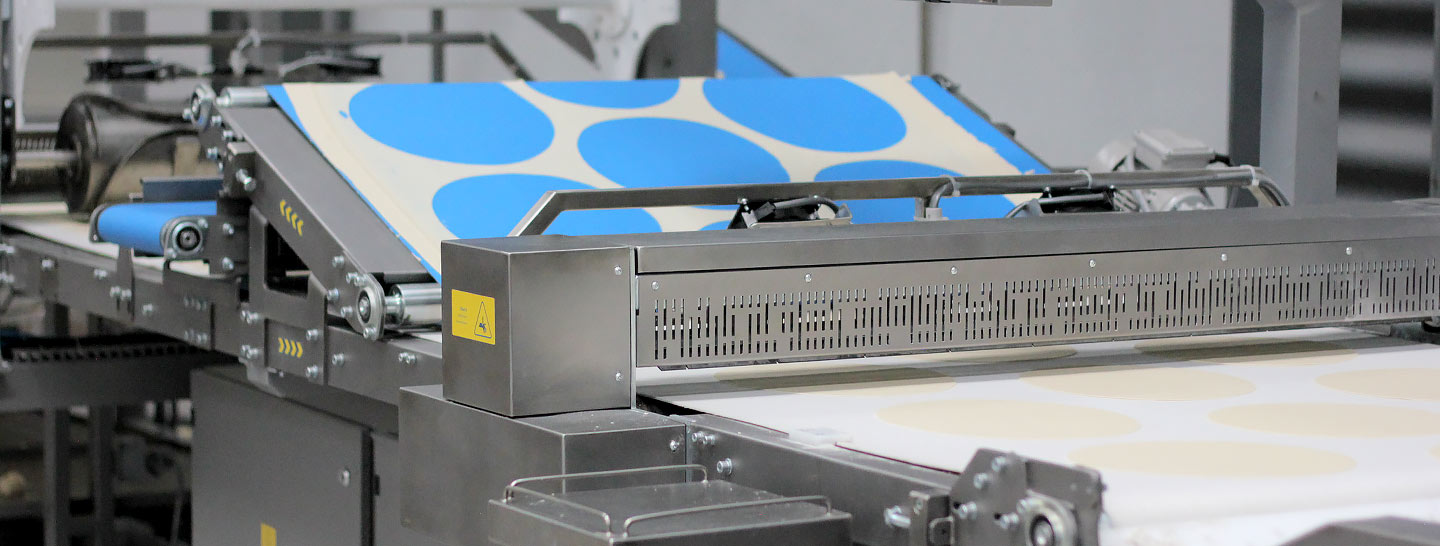

A line for thin lavash production was installed in Ukraine

An automatic line with a capacity of up to 2000 pieces of lavash per hour was manufactured and launched on the territory of Ukraine.

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

AUTOMATIC LINE FOR LAVASH PRODUCTION WITH THE CAPACITY OF 100 KG/H

More

More

More

More

More

More

More

More