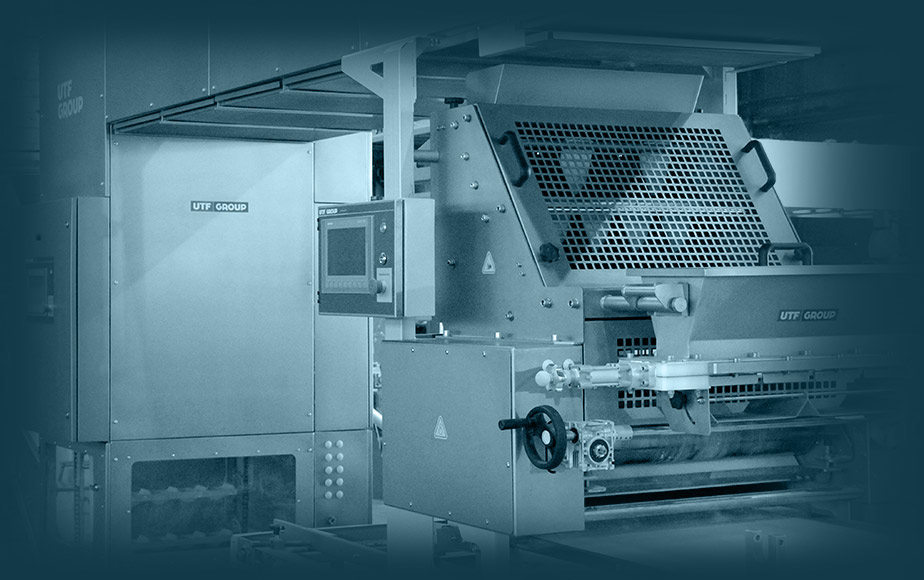

АВТОМАТИЗИРОВАННАЯ ЛИНИЯ ДЛЯ ПРОИЗВОДСТВА МАТНАКАША

Низкая себестоимость производства матнакаша. Автоматизация технологического процесса. Возможность выпуска других подовых хлебов. Соответствие европейским требованиям пищевой безопасности.

Автоматические линии для производства лаваша

Автоматические линии для производства лаваша