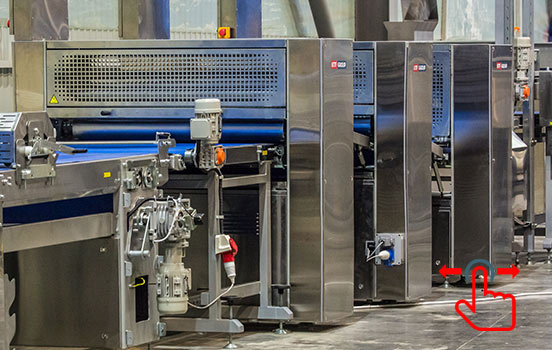

ТЕСТОПОДГОТОВИТЕЛЬНОЕ ОБОРУДОВАНИЕ

Предварительно подготовленные просеянная мука и подогретая вода подаются в миксер при помощи автоматических дозаторов. Обеспечивается минимальное время контакта воды с мукой.

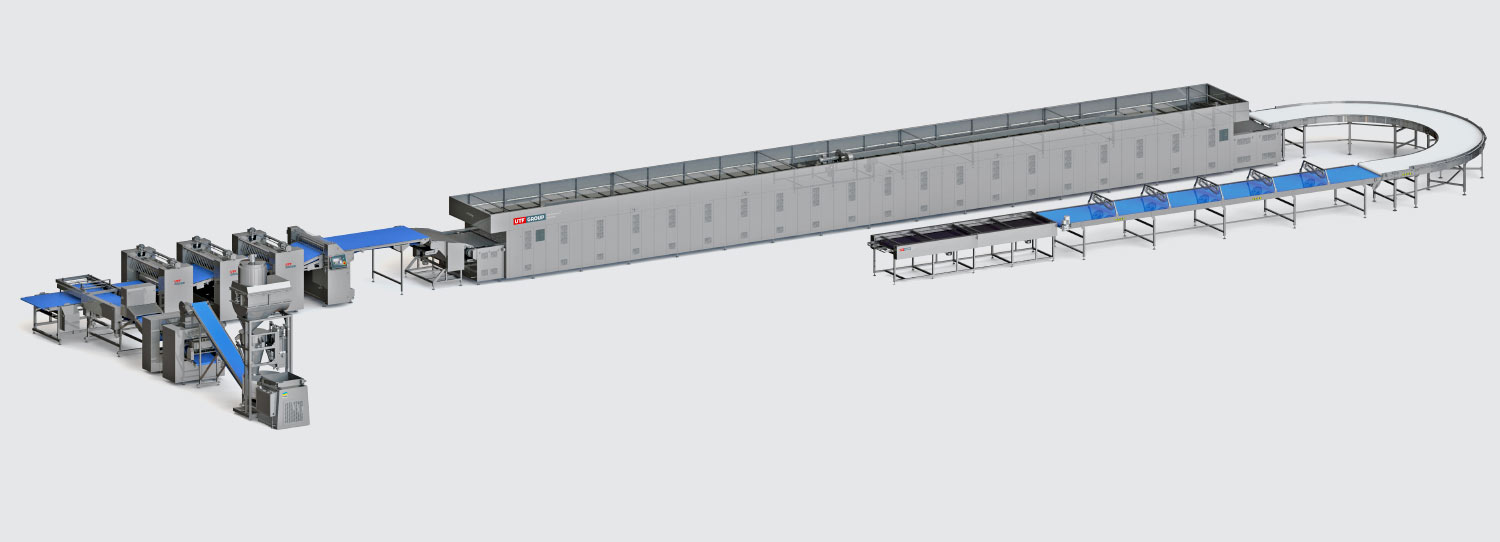

Производительность линии 1000 кг/ч

Позволяет производить кошерную мацу. Исключает задержку теста в процессе производства. Цикл производства готового изделия составляет меньше 18 минут.

Высокая производительность и автоматизация всего техпроцесса.

UTF GROUP - украинский завод-изготовитель, разработчик и проектировщик оборудования для пищевой промышленности с опытом более 25 лет

МОДЕРНИЗИРУЙТЕ СВОЕ ПРОИЗВОДСТВО С ОБОРУДОВАНИЕМ UTF GROUP

ПРОИЗВОДИТЕЛЬНОСТЬ

1000 КГ/ЧАС

ВРЕМЯ ВЫПЕЧКИ

1.5 МИН

ГОТОВЫЙ ПРОДУКТ

< 10 МИН

ТЕМПЕРАТУРА ВЫПЕЧКИ

380-400 °С

ОБСЛУЖИВАЮЩИЙ ПЕРСОНАЛ

3 ЧЕЛОВЕКА

Предварительно подготовленные просеянная мука и подогретая вода подаются в миксер при помощи автоматических дозаторов. Обеспечивается минимальное время контакта воды с мукой.

Валковый экструдер формирует тестовую ленту для мацы, при этом конструкция бункера и системы валков исключает задержку теста.

Выполняет калибровку тестовой ленты по толщине с исключением задержки теста в элементах машины.

Порезка гильотиной пластов тестовой ленты равной длины и их поперечная укладка в несколько слоев позволяет создать необходимую структуру теста.

Выполняет раскатку теста с получением тестовой ленты необходимой толщины. Конструкция машин исключает задержку теста в элементах оборудования.

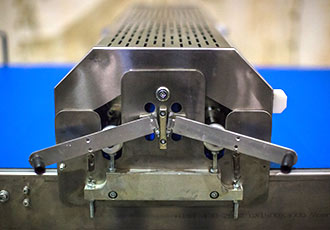

Система дисковых ножей разделяет тестовую ленту на полосы заданной ширины с перфорацией теста специальным блоком. Залипание теста в узлах исключено.

Окончательное получение тестовых заготовок мацы осуществляется узлом поперечной резки, который разделяет полосы теста на заготовки заданной длины.

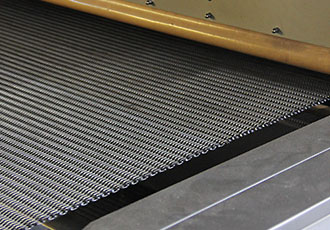

Конвейер с металлической сетчатой лентой может работать с горячими элементами туннельной печи. Выполняет автоматическую укладку заготовок мацы на сетчатый под печи.

Выпекает мацу на металлическом сетчатом поде в пекарной камере с несколькими температурными зонами имеющими индивидуальную регулировку нагрева для оптимального и быстрого процесса выпечки.

Охлаждает готовую мацу после выпечки до комнатной температуры. Представляет собой систему конвейеров, спроектированную с учетом планировки помещения и упаковочного оборудования.

ХОТИТЕ ПОЛУЧИТЬ КОММЕРЧЕСКОЕ

ПРЕДЛОЖЕНИЕ?

УЗНАТЬ СТОИМОСТЬ ЛИНИИ

И ДОПОЛНИТЕЛЬНОГО ОБОРУДОВАНИЯ?