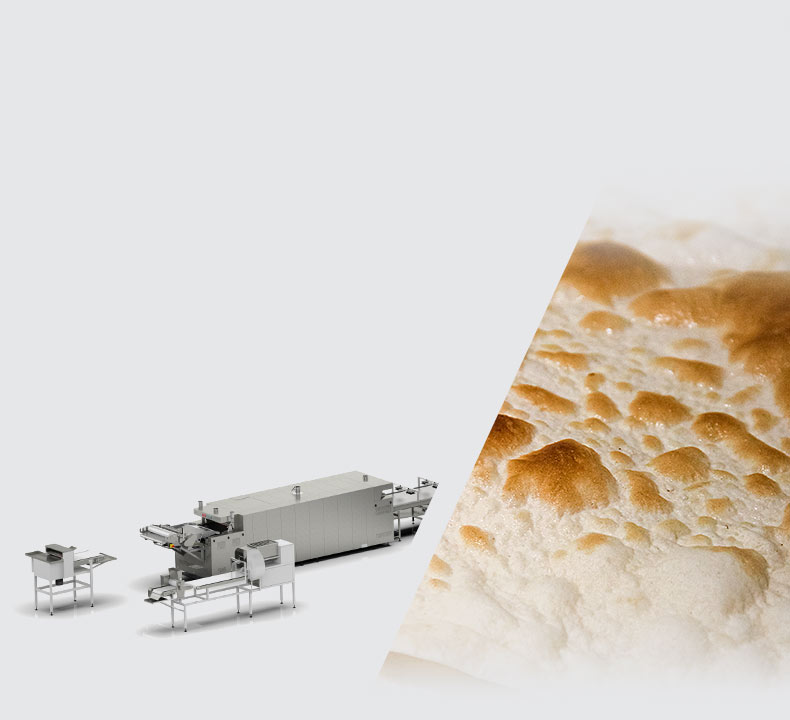

КАЧЕСТВЕННАЯ ПРОДУКЦИЯ

получение лаваша с равномерной толщиной по всей площади (без толстых краев)

Производительность линии до 80 кг/ч

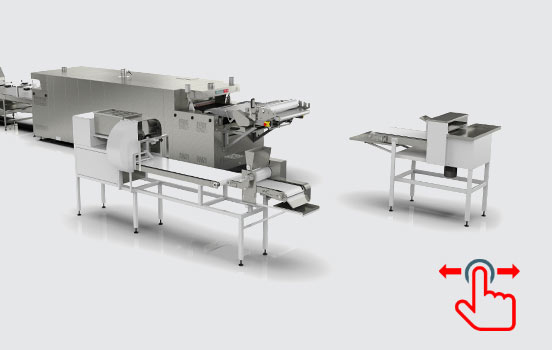

Оптимальный вариант для начала бизнеса. Поэтапная автоматизация и расширение производства. Готовый продукт — лаваш ручной работы. Небольшая занимаемая площадь

Производительность

50-80 кг / час

Потребляемая мощность

от 25 кВт

Занимаемая площадь

от 50 м2

получение лаваша с равномерной толщиной по всей площади (без толстых краев)

возможность работы 24 часа в сутки благодаря качественным материалам и комплектующим

снижение требований к профессиональным навыкам сотрудников за счет автоматизации наиболее сложных операций — формовки и выпечки

размещение оборудования в помещении заказчика по индивидуальному плану

По желанию заказчика линию можно укомплектовать тестоподготовительным оборудованием, оптимизированным для получения лавашного теста.

Возможно полностью автоматизировать процесс производства лаваша с сохранением большинства машин, входящих в состав полуавтоматической линии.

В зависимости от требований заказчика линия комплектуется туннельными печами для выпечки лаваша, работающими на электричестве или природном газе.

Европейское качество и безопасность, подтвержденные сертификатами. Разработка оборудования под конкретный продукт. Запуск оборудования под ключ в любой точке мира.

ХОТИТЕ ПОЛУЧИТЬ КОММЕРЧЕСКОЕ

ПРЕДЛОЖЕНИЕ?

УЗНАТЬ СТОИМОСТЬ ЛИНИИ

И ДОПОЛНИТЕЛЬНОГО ОБОРУДОВАНИЯ?