ЗАТЯЖНЕ ПЕЧИВО

Дієтичне затяжне печиво виготовляють із тіста з низьким вмістом жиру та цукру. Пружне та еластичне затяжне тісто вимагає тривалого багатоетапного прокочування з відлежкою між етапами, чому і називається затяжним.

Виробництво автоматичних ліній та іншого обладнання для печива різних видів: цукрового, затяжного, галетного, пісочного (відсадного), печива з начинкою, крекерів.

Стабільна якість готової продукції, мінімальний брак та низькі витрати на виробництво, максимальне виключення людського фактору.

UTF GROUP - український виробник, розробник та проектувальник обладнання для харчової промисловості з досвідом понад 25 років.

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Дієтичне затяжне печиво виготовляють із тіста з низьким вмістом жиру та цукру. Пружне та еластичне затяжне тісто вимагає тривалого багатоетапного прокочування з відлежкою між етапами, чому і називається затяжним.

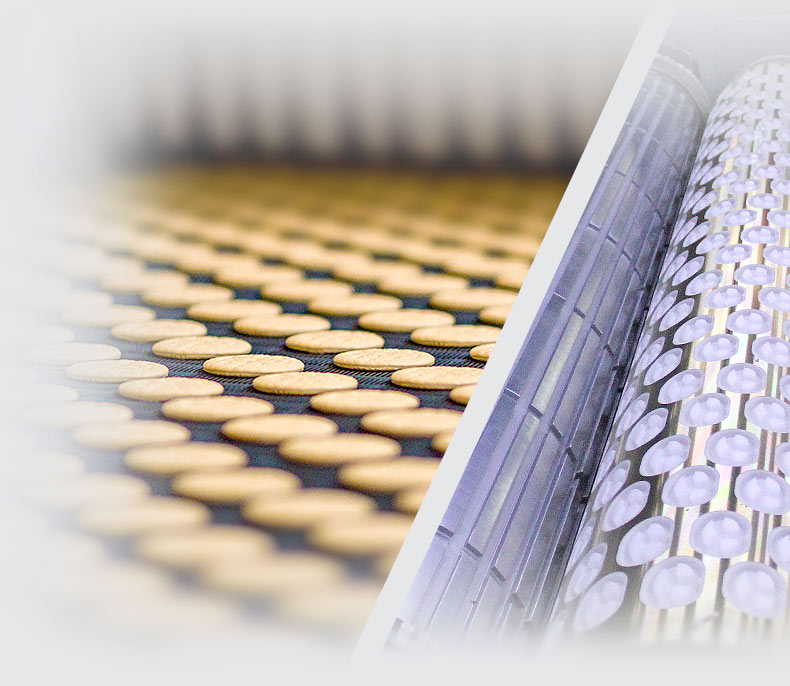

Розсипчасте та солодке цукрове печиво виготовляється з густого пластичного тіста. Це печиво за рахунок формування в осередках роторної машини дозволяє легко отримати будь-який візерунок на поверхні.

До відсадного належать кілька видів печива, які поєднує технологія формування заготовок видавлюванням через насадки безпосередньо на сталевий лист печі.

Виробництво печива починається із приготування тіста. Після дозування та подачі компонентів тіста змішувач виконує його змішування в горизонтальних тістомісах крутого тіста.

При виробництві затяжного печива необхідне розстоювання тіста, воно може бути прискорена за рахунок внесення домішок або застосування окремої ферментаційної камери з оптимальними умовами для розстоювання.

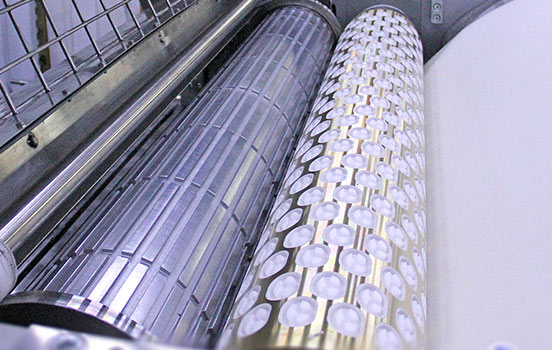

Для отримання затяжного печива виконується формування стрічки тіста за допомогою екструдера. Сформована стрічка пропускається через ламінатор із багаторазовою прокаткою та відлежкою.

Для затяжного печива заготовки вирізують із тестової стрічки формуючим ротором, який вирубує заготовки із заданою формою, розмірами та малюнком поверхні.

Для розширення номенклатури готової продукції виконується декорування печива швидкомонтованими декоруючими машинами, які можуть встановлюватися як до випічки, так і після.

Випікання виконується на кондитерських тунельних печах довжиною до 40 м і шириною пода до 1200 мм з широким діапазоном регулювання для забезпечення оптимальної випічки печива різних видів.

Охолодження готового продукту до температури упаковки виконується на конвеєрній системі охолодження, розміри і склад якої визначаються в залежності від продукту, що випускається, і компонування лінії.

Для цукрового печива формування заготовок проводиться безпосередньо штампуванням із тіста.

Формуючі ділянки для одержання цукрового та затяжного печива можуть бути встановлені для роботи на одну піч. У цьому випадку можливий швидкий перехід із одного виду печива на інший.

Велике виробництво печива потребує автоматизації процесу пакування. Для автоматизації упаковки в пачки потрібно попередньо впорядкувати печиво в стопки, для чого застосовується машина-стекер.

Для отримання широкого асортименту форм і розмірів печива застосовуються швидкозмінні ротори для машин, що формують. Їх виготовлення проводиться на замовлення за каталогом або ескізами замовника.

При виробництві із затяжного печива залишається значна кількість обрізків тіста, що може використовуватися повторно. При цьому воно може повертатися в екструдер лінії або подаватися додатковий екструдер.

На лінії можливе виготовлення сендвіч-печива.

Для цього виконується поділ печива після випікання на два потоки — на першому печиві перевертають і наносять начинку, після чого зверху виконується укладання печива з другого потоку та накочування.

Формування тестових заготовок відсадного печива виконується головками відсадження, які в процесі відсадки можуть обертатися і переміщатися в двох площинах.

Для випікання відсадного печива застосовують тунельні печі зі сталевим подом із нанесеним на нього шаром жиру.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?

Печиво – це один із небагатьох видів кондитерських виробів, який є продуктом повсякденного споживання, що забезпечує стабільний попит та високу рентабельність його виробництва.

Існують різні види печива, що відрізняються застосовуваним тестом та технологією виробництва, а також широке розмаїття смаків, розмірів, форм, малюнків, наявності посипання (цукор, сіль, подрібнені горіхи тощо), глазурування та інших елементів.

Для організації інноваційного та економічно ефективного підприємства недостатньо просто купити обладнання для виробництва печива, значно важливіше правильно організувати технологічний процес з урахуванням планованої продуктивності, майбутнього асортименту, планування приміщення та багатьох інших факторів. Компанія надає кваліфіковані консультації клієнтам з питань організації виробництва, технології випуску, розширення асортименту. Ми маємо великий досвід реалізації комплексних проектів з виробництва різних видів печива, у тому числі виконаних “під ключ”.