EQUIPMENT FOR DOUGH PREPARATION

provides an efficient process for obtaining dough from the dosing of raw materials to the supply of the finished dough to the preparation area

Capacity is 100 kg/h

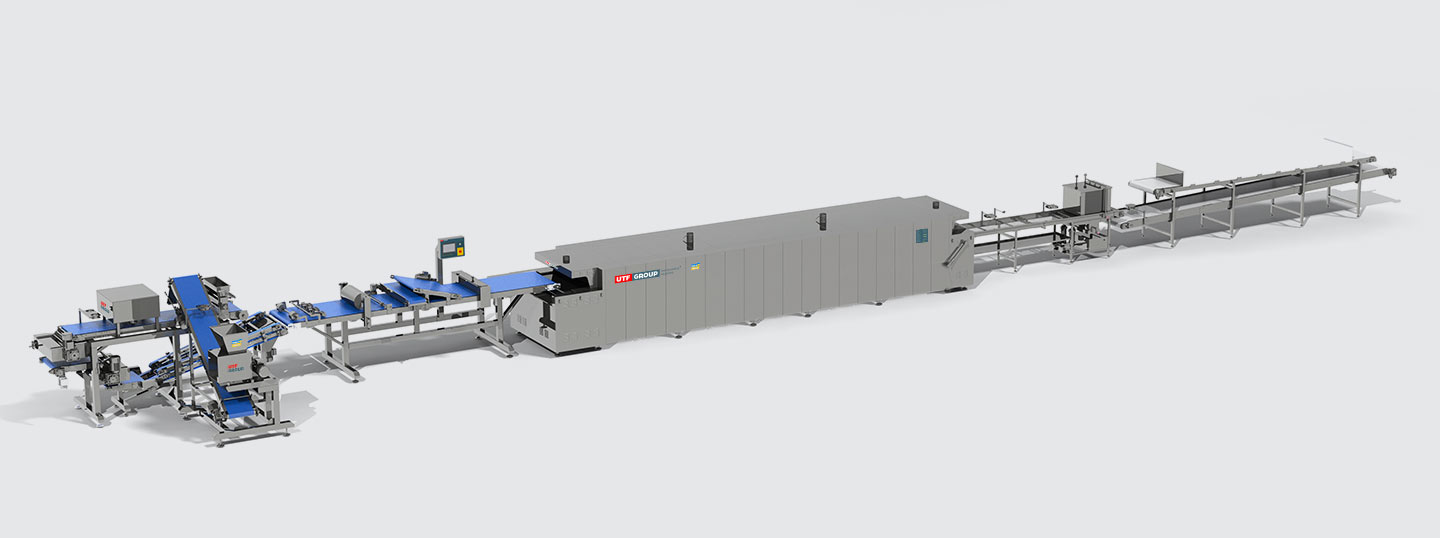

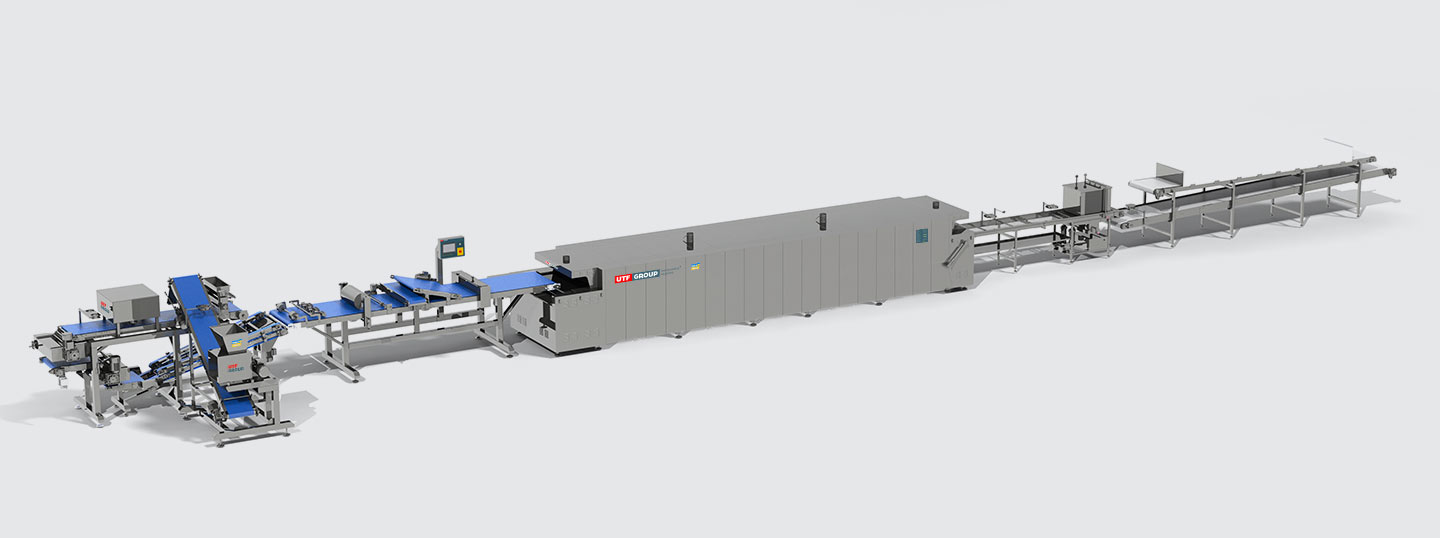

Automation of the entire production process from forming to packaging. Round-the-clock work of the line for maximum economic return. Certificate of compliance with European safety and hygiene standards.

Individual project for optimal placement of equipment in the workshop

UTF GROUP is a Ukrainian manufacturer, developer and designer of equipment for the food industry with over 25 years of experience.

UPGRADE YOUR PRODUCTION WITH UTF GROUP MACHINERY

CAPACITY

UP TO 100 KG/HOUR

OPERATING MODE

ROUND-THE-CLOCK

ENERGY SOURCE

ELECTRICITY OR GAS

EQUIPMENT AREA

FROM 130 M2

POWER CONSUMPTION

60 kW

INSTALLED CAPACITY

90 kW

provides an efficient process for obtaining dough from the dosing of raw materials to the supply of the finished dough to the preparation area

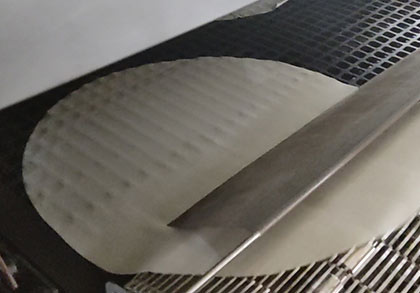

designed for forming a thin dough ribbon, its rolling and stretching up to 0.2 mm thick with a wide range of regulation

Formation of lavash of various shapes from a dough ribbon (round, oval, rectangular, rounded edges)

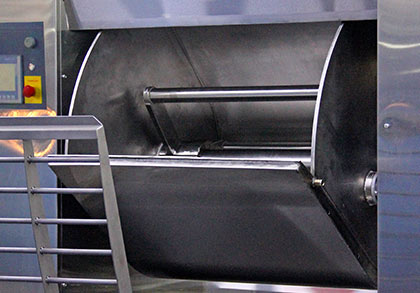

designed for baking lavash in optimal conditions with minimal heat loss

designed to automatically humidifying the surface of baked thin lavash with water to make it soft and flexible

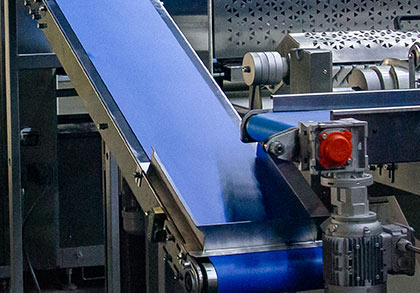

On the stabilization conveyor, lavash reaches normal temperature and humidity

the process of obtaining the finished dough from the dosing of raw materials

provides an efficient process for obtaining dough from the dosing of raw materials to the supply of the finished dough to the preparation area

Automatic return of dough scraps to the extruder hopper after forming dough pieces on the knife table

It is possible to install a rotary knife module with four replaceable cutting drums for the convenience and speed of transition to the production of lavash of another size or shape.

Would you like to receive a

commercial offer?

Ask quotation of the line

and additional equipment?