ПІТА

Піта (пітта) — круглий, плоский прісний хліб, який готується як з борошна грубого помелу, так і з борошна пшеничного вищого гатунку. Надзвичайно популярний на узбережжі Середземного моря та у країнах Близького Сходу.

Виробництво обладнання

для виготовлення різних видів піти.

Автоматичні та напівавтоматичні лінії з продуктивністю від 1200 до 7200 одиниць на годину дають можливість організувати як невелике виробництво, так і велике підприємство з випуску піти.

UTF-GROUP, один із найбільших виробників промислових ліній та обладнання для виробництва національних видів хліба у Східній Європі.

МОДЕРНІЗУЙТЕ СВОЄ ВИРОБНИЦТВО З ОБЛАДНАННЯМ UTF GROUP

Піта (пітта) — круглий, плоский прісний хліб, який готується як з борошна грубого помелу, так і з борошна пшеничного вищого гатунку. Надзвичайно популярний на узбережжі Середземного моря та у країнах Близького Сходу.

Існує багато різновидів: арабська піта, грецька, ізраїльська, іракські лафи і т.і.

Відмінна риса традиційної піти полягає в тому, що водяна пара, що утворюється в тісті при випіканні, накопичується в міхурі в центрі піти, розділяючи шари тіста.

Таким чином, усередині піти утворюється «кишеня», яку можна відкрити, надрізавши край гострим ножем. У «кишеню» можна покласти салати, м’ясо та іншу начинку.

Автоматичний дільник тесту видає задані порції тіста, які подаються на попереднє вистоювання. Формування заготовок виконується після вистоювання розкочувальними машинами послідовним розкочуванням у двох перпендикулярних напрямках.

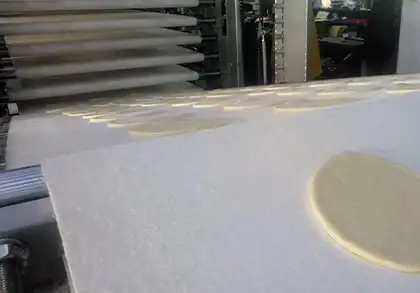

Іншою технологією виробництва піти є висікання заготовки із стрічки тіста. Екструдер формує стрічку, з якої ріжучі барабани пластиковими ножами з широкою закругленою кромкою отримують заготовки з пресованими краями.

Необхідним етапом виробництва піти є розстоювання. Двоетапне розстоювання тіста в конвеєрних камерах забезпечує отримання готової продукції високої якості в автоматичному режимі.

Деякі різновиди пити не вимагають двох етапів розстоювання тесту. У цьому випадку використовується тільки одна камера розстоювання.

Випікання піти виконується в траковій тунельній печі з електричним або газовим нагріванням. Піч оптимізована для випікання національних видів хліба.

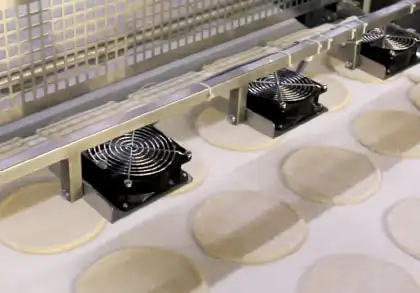

Для економії місця використовуються складні технічні рішення: багаторівневі або спіральні конвеєри, системи примусового охолодження і т.п.

Бажаєте отримати комерційну

пропозицію?

Дізнатися вартість ліній

та додаткового обладнання?

Важливим елементом автоматизації виробництва піти є автоматизація вистоювання. Цей процес повинен виконуватися у два етапи: перший перед розкочуванням, другий перед випіканням. Конвеєрні камери забезпечують розстоювання, не перериваючи технологічний процес.

Для максимальної економії місця розстоювальні камери мають багатоярусну конструкцію та складну траєкторію руху.