ПРОИЗВОДИТЕЛЬНОСТЬ

Туннельные печи разработаны для обработки больших объемов продукции, что делает их идеальными для промышленного производства.

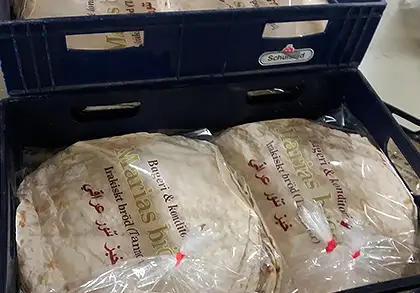

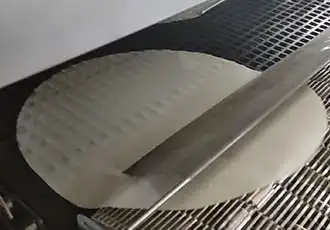

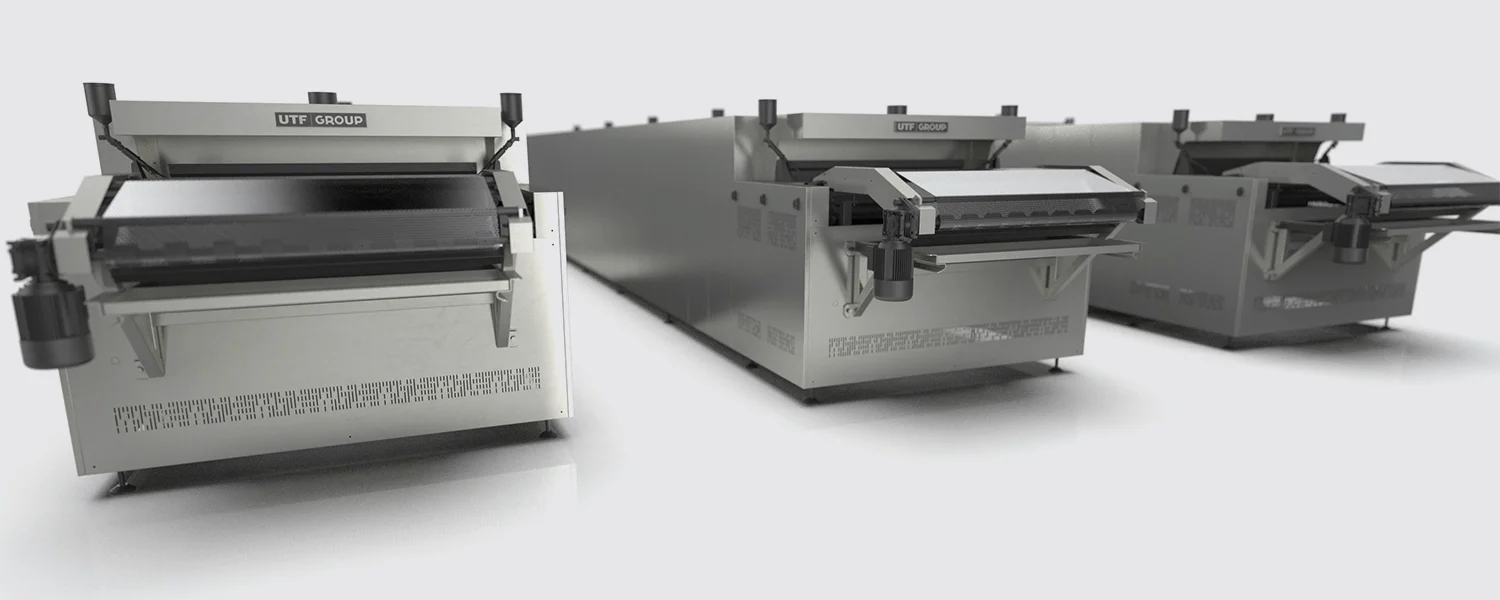

Туннельная печь с траковым подом специально создана для изготовления лаваша и других подобных национальных видов хлеба, благодаря чему обеспечивает оптимальные условия для их выпечки.

Туннельные печи предназначены для автоматической выпечки продукта и применяются при массовом производстве хлебобулочных, кондитерских и снековых изделий.

Туннельные печи разработаны для обработки больших объемов продукции, что делает их идеальными для промышленного производства.

Это позволяет значительно увеличить производственные мощности и эффективность, сокращая время выпечки и снижая затраты на производство.

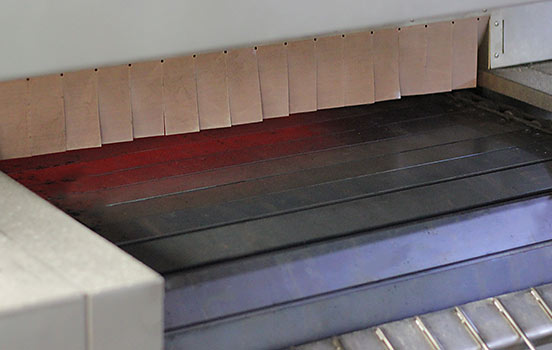

Печи обеспечивают двустороннюю выпечку изделий на металлических траках и управление параметрами нагревательных элементов.

Туннельные печи обычно оснащены автоматическим управлением температурой, регулировкой скорости конвейеров и другими параметрами.

Теплоизоляция на основе базальтового волокна, закрытая кожухами конструкция печи и минимальные зазоры на входе и выходе из пекарной камеры обеспечивают минимальные потери тепла.

Устройство автоматической смазки цепей, неметаллические направляющие и закрытые кожухами подвижные части обеспечивают минимальный уровень уровень шума.

Печи спроектированы для оптимального использования доступной площади производственных помещений.

Комплектующие рассчитанные на работу в условиях высоких температур и внешняя обшивка из нержавеющей стали обеспечивают непрерывную долговременную работу печи без необходимости ремонта.

Могут использоваться для выпечки ряда других плоских хлебных изделий, включая некоторые виды питы и тортильи.

Траки с фигурными вырезами позволяют выпускать лаваш с индивидуальным рисунком поверхности.

ПРОИЗВОДИТЕЛЬНОСТЬ ПЕЧЕЙ

500 / 300 / 200 / 100 КГ/Ч

ДЛИНА ПЕКАРНОЙ КАМЕРЫ

3-10 М

ШИРИНА ПОДА

650-1000 ММ

ЭНЕРГОНОСИТЕЛЬ НАГРЕВА ПЕЧИ

ЭЛЕКТРИЧЕСТВО ИЛИ ГАЗ

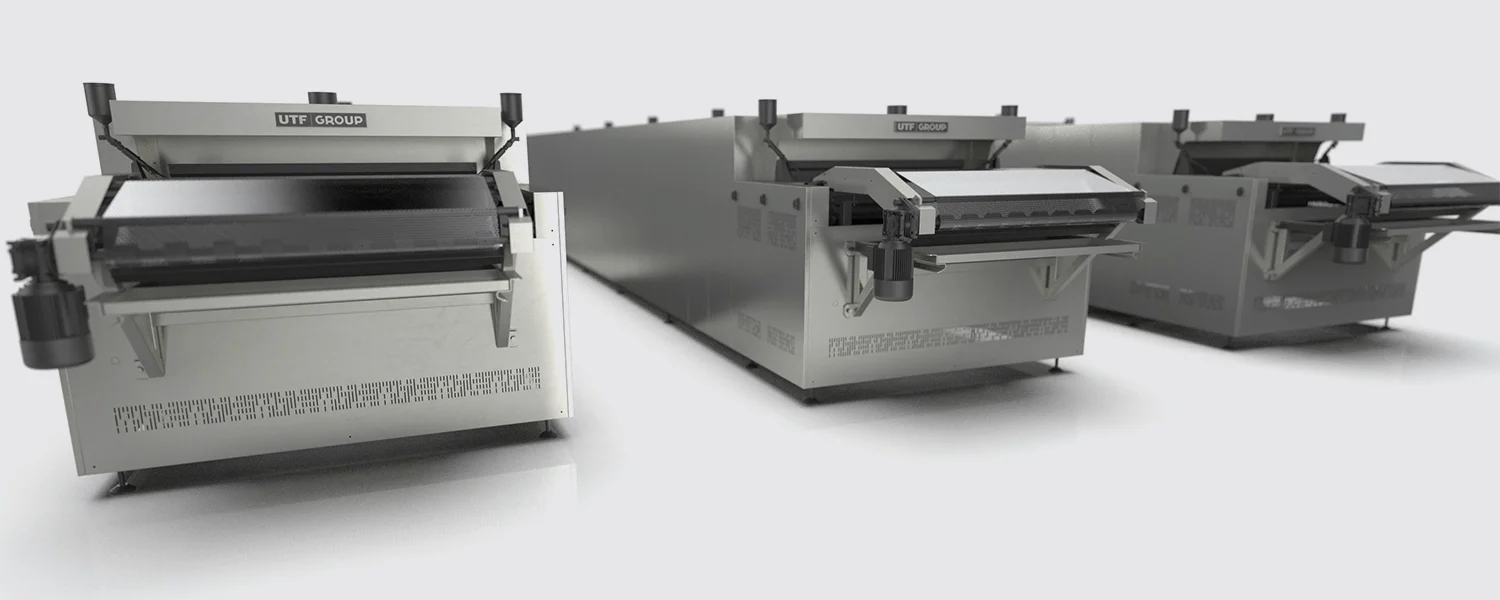

Предлагаем туннельные траковые печи с двусторонним расположением ТЭНов. В зависимости от требуемой производительности печи имеют различную длину пекарной камеры и ширину траков.

Применение инфракрасных ТЭНов с передачей энергии излучением и повышенной энергоотдачей существенно расширяет возможности печи.

Вместо электрического нагрева в туннельных печах может применяться газовый. Источником тепла в таких печах могут быть газовые горелки или газовые инфракрасные излучатели.

ХОТИТЕ ПОЛУЧИТЬ КОММЕРЧЕСКОЕ

ПРЕДЛОЖЕНИЕ?

УЗНАТЬ СТОИМОСТЬ ЛИНИИ

И ДОПОЛНИТЕЛЬНОГО ОБОРУДОВАНИЯ?

Длина пекарной камеры

10 м

—

Ширина пода печи

1000 мм

Длина пекарной камеры

7.5 м

—

Ширина пода печи

1000 мм

Длина пекарной камеры

6 м

—

Ширина пода печи

1000 мм

Длина пекарной камеры

4 м

—

Ширина пода печи

650 мм

Длина пекарной камеры

3 м

—

Ширина пода печи

650 мм

Длина пекарной камеры

4 м

—

Ширина пода печи

650 мм