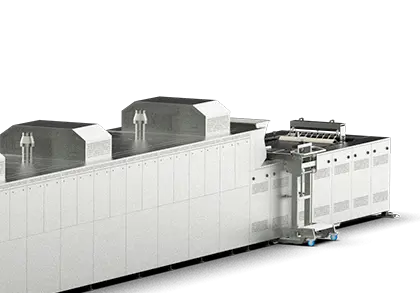

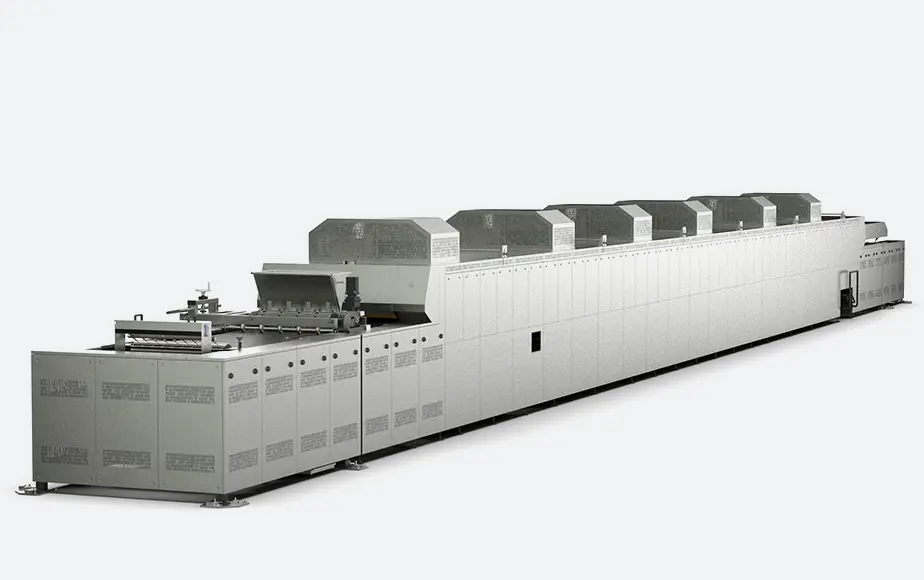

Мы разрабатываем и производим оборудование, на котором можно выпускать заварные пирожные различных видов и размеров. Наши машины и линии отличаются современным дизайном, эргономичностью, высоким уровнем пищевой и производственной безопасности.

ОБОРУДОВАНИЕ ДЛЯ ПРОИЗВОДСТВА ЭКЛЕРОВ И ПРОФИТРОЛЕЙ

Наша компания занимается производством промышленного оборудования для эклеров, профитролей, заварных палочек и других изделий из заварного теста.

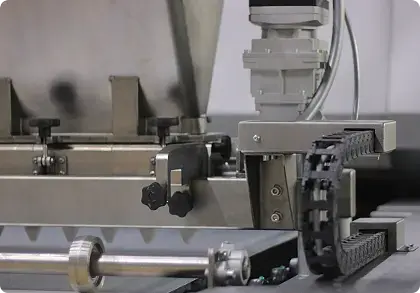

UTF GROUP разрабатывает и выпускает автоматические линии и агрегаты с производительностью до 10 000 штук в час. В ассортимент оборудования входят туннельные печи, машины для отсадки заварного теста, устройства для наполнения начинкой и другие устройства.

Автоматические линии для производства лаваша

Автоматические линии для производства лаваша