ТЕСТОПОДГОТОВКА

Для приготовления теста для затяжного печенья применяются системы подачи и дозирования муки и воды, а также горизонтальный тестомес с гидравлическим опрокидыванием. Готовое тесто подается в дежу или в конвейерную систему подачи теста.

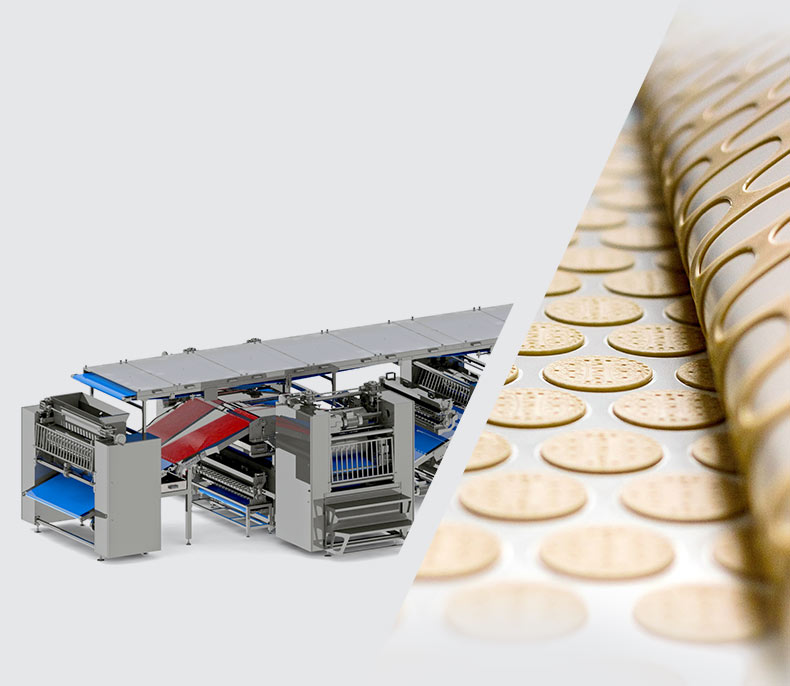

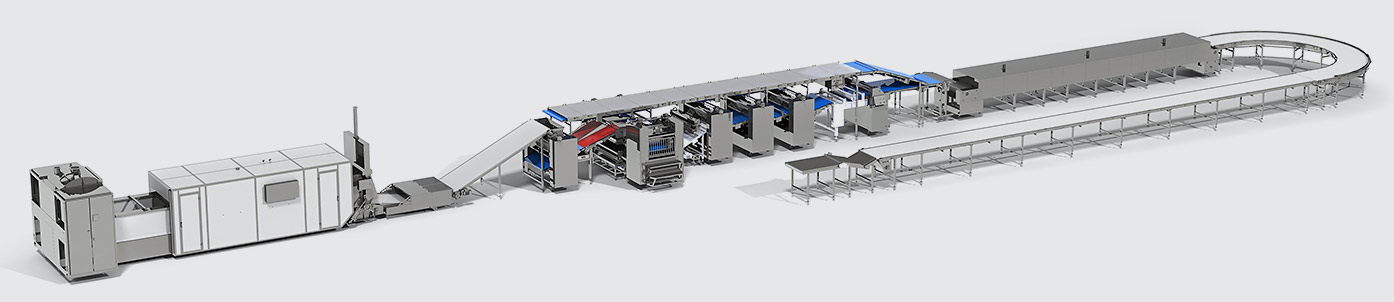

Автоматические линии для производства лаваша

Автоматические линии для производства лаваша